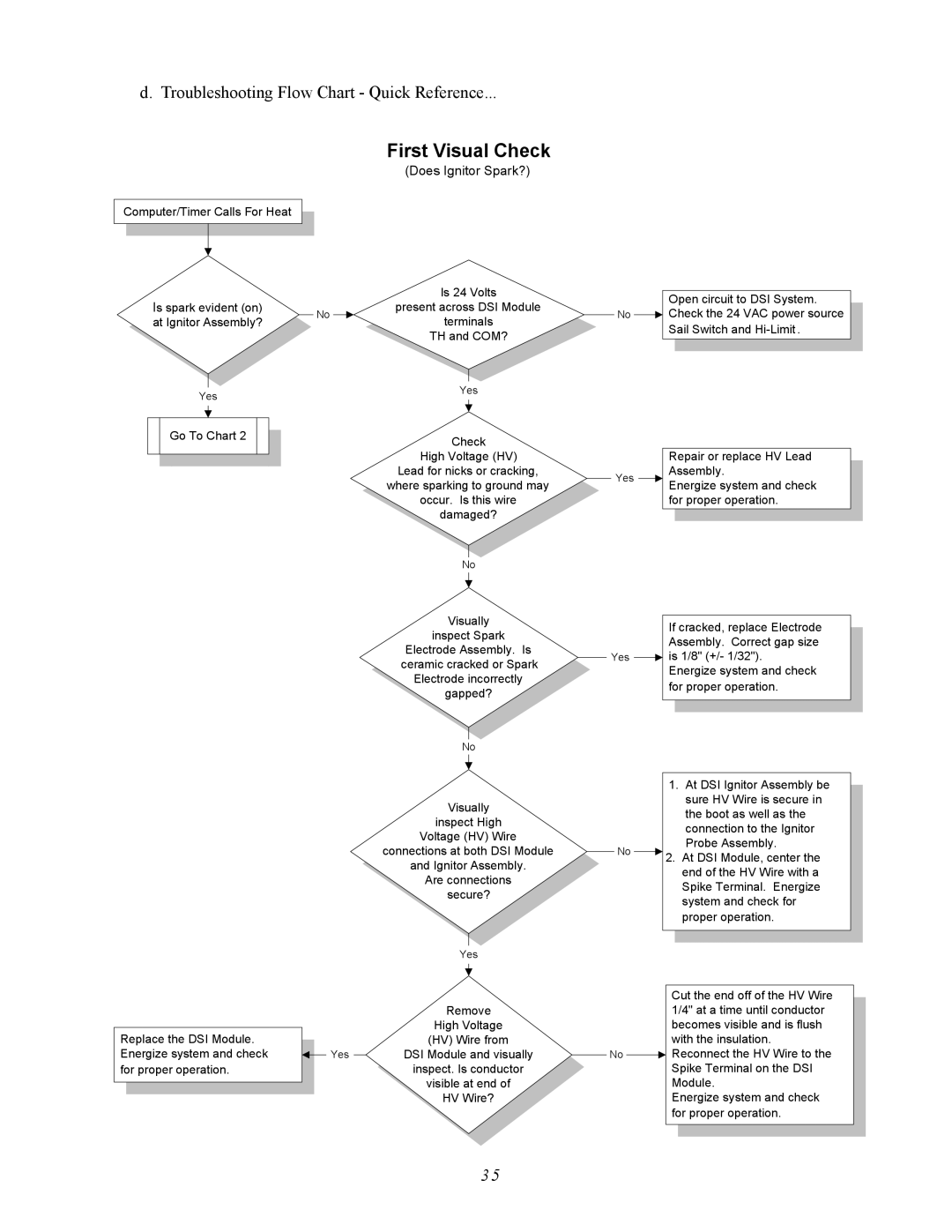

d. Troubleshooting Flow Chart - Quick Reference...

First Visual Check

(Does Ignitor Spark?)

Computer/Timer Calls For Heat

Is spark evident (on) |

|

|

| Is 24 Volts | ||||||

|

|

| present across DSI Module | |||||||

| No |

| ||||||||

at Ignitor Assembly? |

|

| terminals | |||||||

|

|

| ||||||||

|

|

|

|

|

|

| TH and COM? | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Yes |

| |

| Yes |

|

|

| ||||||

|

|

|

|

|

|

|

|

| ||

Open circuit to DSI System.

No ![]() Check the 24 VAC power source Sail Switch and

Check the 24 VAC power source Sail Switch and

Go To Chart 2

Replace the DSI Module. Energize system and check for proper operation.

Check

High Voltage (HV) Lead for nicks or cracking,

where sparking to ground may

occur. Is this wire

damaged?

No

Visually

inspect Spark

Electrode Assembly. Is ceramic cracked or Spark Electrode incorrectly gapped?

No

Visually

inspect High

Voltage (HV) Wire

connections at both DSI Module

and Ignitor Assembly.

Are connections

secure?

Yes

Remove

High Voltage (HV) Wire from

![]() Yes DSI Module and visually inspect. Is conductor

Yes DSI Module and visually inspect. Is conductor

visible at end of

HV Wire?

| Repair or replace HV Lead | |

Yes | Assembly. | |

Energize system and check | ||

| ||

| for proper operation. |

If cracked, replace Electrode Assembly. Correct gap size

Yes ![]() is 1/8" (+/- 1/32"). Energize system and check

is 1/8" (+/- 1/32"). Energize system and check

for proper operation.

1.At DSI Ignitor Assembly be sure HV Wire is secure in the boot as well as the connection to the Ignitor

Probe Assembly.

No ![]() 2. At DSI Module, center the end of the HV Wire with a Spike Terminal. Energize system and check for proper operation.

2. At DSI Module, center the end of the HV Wire with a Spike Terminal. Energize system and check for proper operation.

Cut the end off of the HV Wire 1/4" at a time until conductor becomes visible and is flush with the insulation.

No ![]() Reconnect the HV Wire to the Spike Terminal on the DSI Module.

Reconnect the HV Wire to the Spike Terminal on the DSI Module.

Energize system and check for proper operation.

3 5