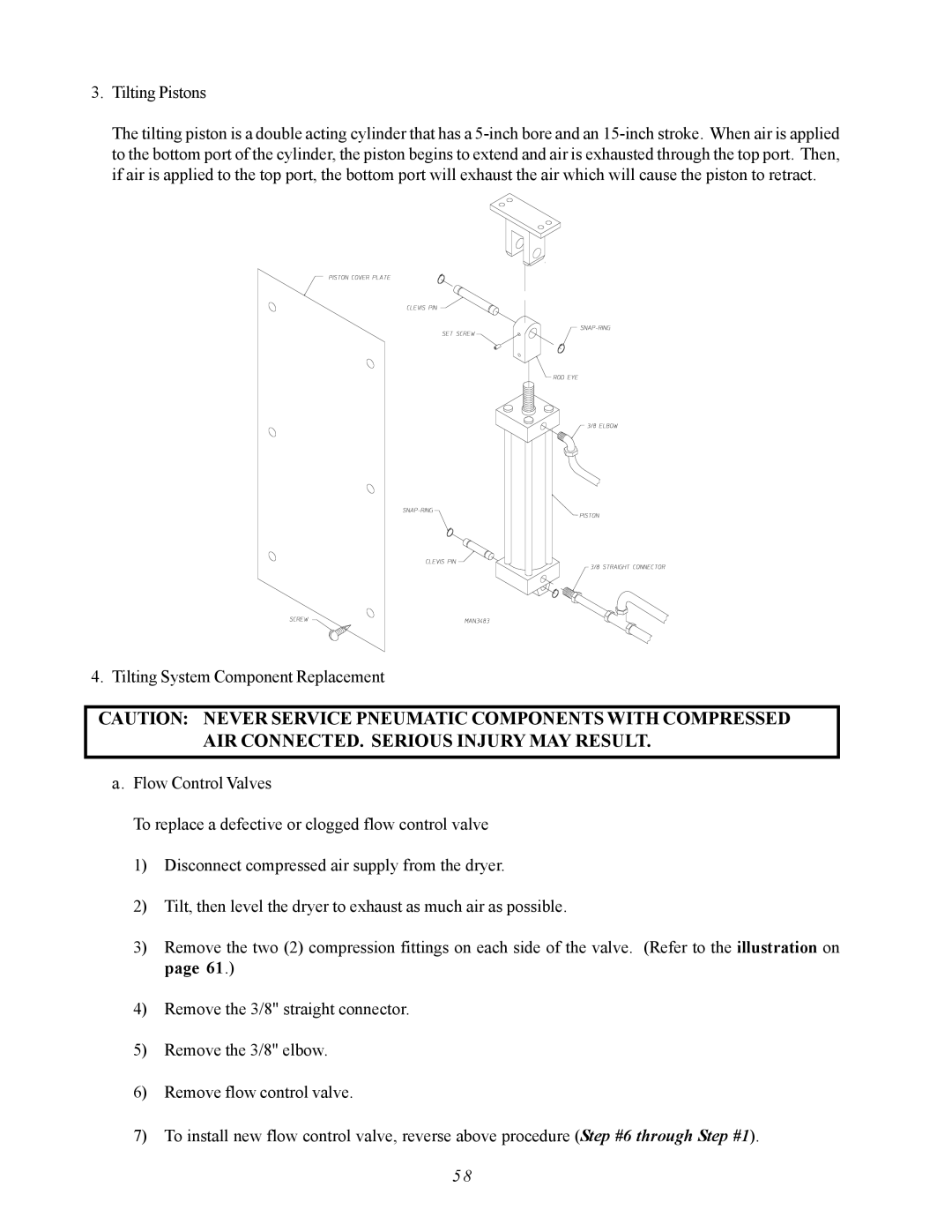

3.Tilting Pistons

The tilting piston is a double acting cylinder that has a

4. Tilting System Component Replacement

CAUTION: NEVER SERVICE PNEUMATIC COMPONENTS WITH COMPRESSED AIR CONNECTED. SERIOUS INJURY MAY RESULT.

a.Flow Control Valves

To replace a defective or clogged flow control valve

1)Disconnect compressed air supply from the dryer.

2)Tilt, then level the dryer to exhaust as much air as possible.

3)Remove the two (2) compression fittings on each side of the valve. (Refer to the illustration on page 61.)

4)Remove the 3/8" straight connector.

5)Remove the 3/8" elbow.

6)Remove flow control valve.

7)To install new flow control valve, reverse above procedure (Step #6 through Step #1).

5 8