a. System Diagnosis

1) Gas Pressure

A gas pressure test should be taken at the gas valve pressure tap provided on every gas valve to assure that the water column (W.C.) pressure is correct and consistent.

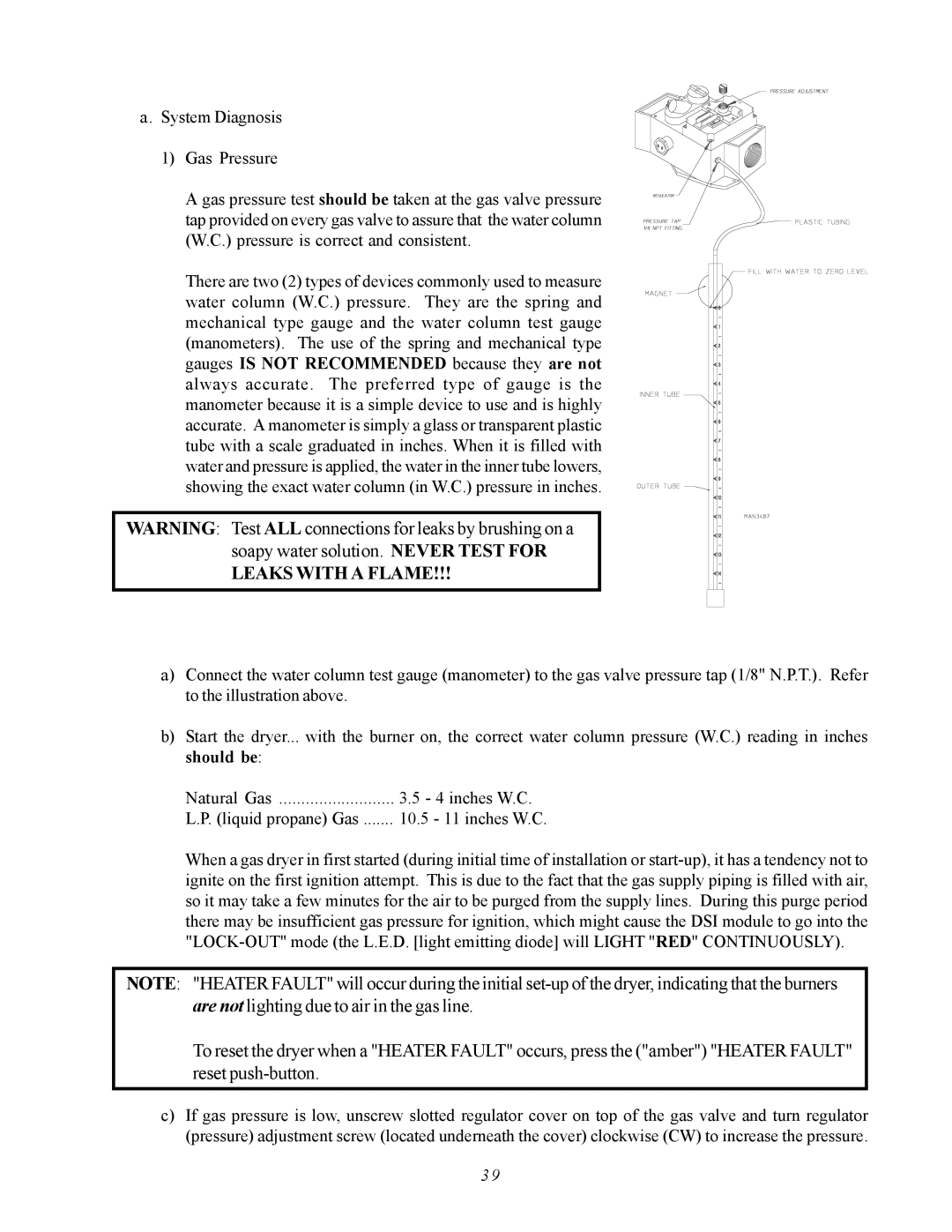

There are two (2) types of devices commonly used to measure water column (W.C.) pressure. They are the spring and mechanical type gauge and the water column test gauge (manometers). The use of the spring and mechanical type gauges IS NOT RECOMMENDED because they are not always accurate. The preferred type of gauge is the manometer because it is a simple device to use and is highly accurate. A manometer is simply a glass or transparent plastic tube with a scale graduated in inches. When it is filled with water and pressure is applied, the water in the inner tube lowers, showing the exact water column (in W.C.) pressure in inches.

WARNING: Test ALL connections for leaks by brushing on a soapy water solution. NEVER TEST FOR

LEAKS WITH A FLAME!!!

a)Connect the water column test gauge (manometer) to the gas valve pressure tap (1/8" N.P.T.). Refer to the illustration above.

b)Start the dryer... with the burner on, the correct water column pressure (W.C.) reading in inches should be:

Natural Gas .......................... 3.5 - 4 inches W.C. L.P. (liquid propane) Gas ....... 10.5 - 11 inches W.C.

When a gas dryer in first started (during initial time of installation or

NOTE: "HEATER FAULT" will occur during the initial

To reset the dryer when a "HEATER FAULT" occurs, press the ("amber") "HEATER FAULT" reset

c)If gas pressure is low, unscrew slotted regulator cover on top of the gas valve and turn regulator (pressure) adjustment screw (located underneath the cover) clockwise (CW) to increase the pressure.

3 9