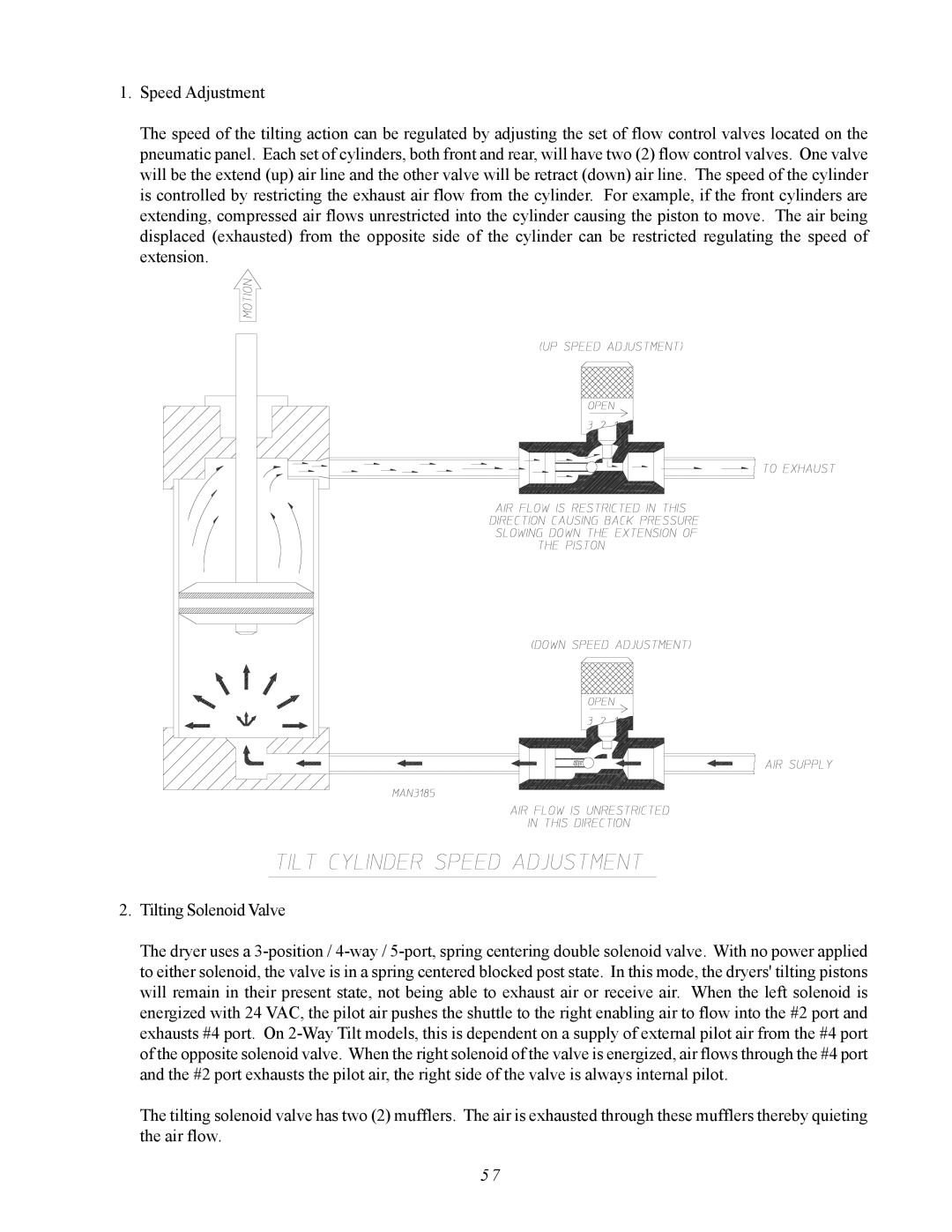

1.Speed Adjustment

The speed of the tilting action can be regulated by adjusting the set of flow control valves located on the pneumatic panel. Each set of cylinders, both front and rear, will have two (2) flow control valves. One valve will be the extend (up) air line and the other valve will be retract (down) air line. The speed of the cylinder is controlled by restricting the exhaust air flow from the cylinder. For example, if the front cylinders are extending, compressed air flows unrestricted into the cylinder causing the piston to move. The air being displaced (exhausted) from the opposite side of the cylinder can be restricted regulating the speed of extension.

2.Tilting Solenoid Valve

The dryer uses a

The tilting solenoid valve has two (2) mufflers. The air is exhausted through these mufflers thereby quieting the air flow.

5 7