Table 1. Specifications and Operating Characteristics (Cont’d)

*REMOTE PROGRAMMING SPEED |

| DC ISOLATION | ||

Maximum time required for output voltage to change from initial | ± 240 Vdc maximum between either output terminal and earth | |||

value to within a tolerance band (0.1%) of the newly programmed | ground including the output voltage. | |||

value following the onset of a step change in the programming |

| |||

input voltage. | Full load | No load | *COOLING: Convection cooling is employed. | |

|

|

| ||

Up: | E3614A: | 3 msec | 2 msec | *WEIGHT: 12.1 lbs/5.5 Kg net, 14.9 lbs/6.75 Kg shipping. |

| E3615A: | 9 msec | 6 msec |

|

| E3616A: | 85 msec | 85 msec | * Operating Characteristics |

| E3617A: | 200 msec | 200 msec |

|

Down: E3614A: | 7 msec | 1.6 sec |

| |

| E3615A: | 13 msec | 2.2 sec |

|

| E3616A: | 65 msec | 1.8 sec |

|

| E3617A: | 200 msec | 3.2 sec |

|

|

|

|

|

|

INSTALLATION

INITIAL INSPECTION

Before shipment, this instrument was inspected and found to be free of mechanical and electrical defects. As soon as the instru- ment is unpacked, inspect for any damage that may have occurred in transit. Save all packing materials until the inspection is completed. If damage is found, a claim should be filed with the carrier. The Agilent Technologies Sales and Service office should be notified.

Mechanical Check

This check should confirm that there are no broken knobs or connec- tors, that the cabinet and panel surfaces are free of dents and scratches, and that the meter is not scratched or cracked.

Electrical Check

The instrument should be checked against its electrical specifi- cations. Paragraph

INSTALLATION DATA

The instrument is shipped ready for bench operation. It is neces- sary only to connect the instrument to a source of power and it is ready for operation.

instructions. |

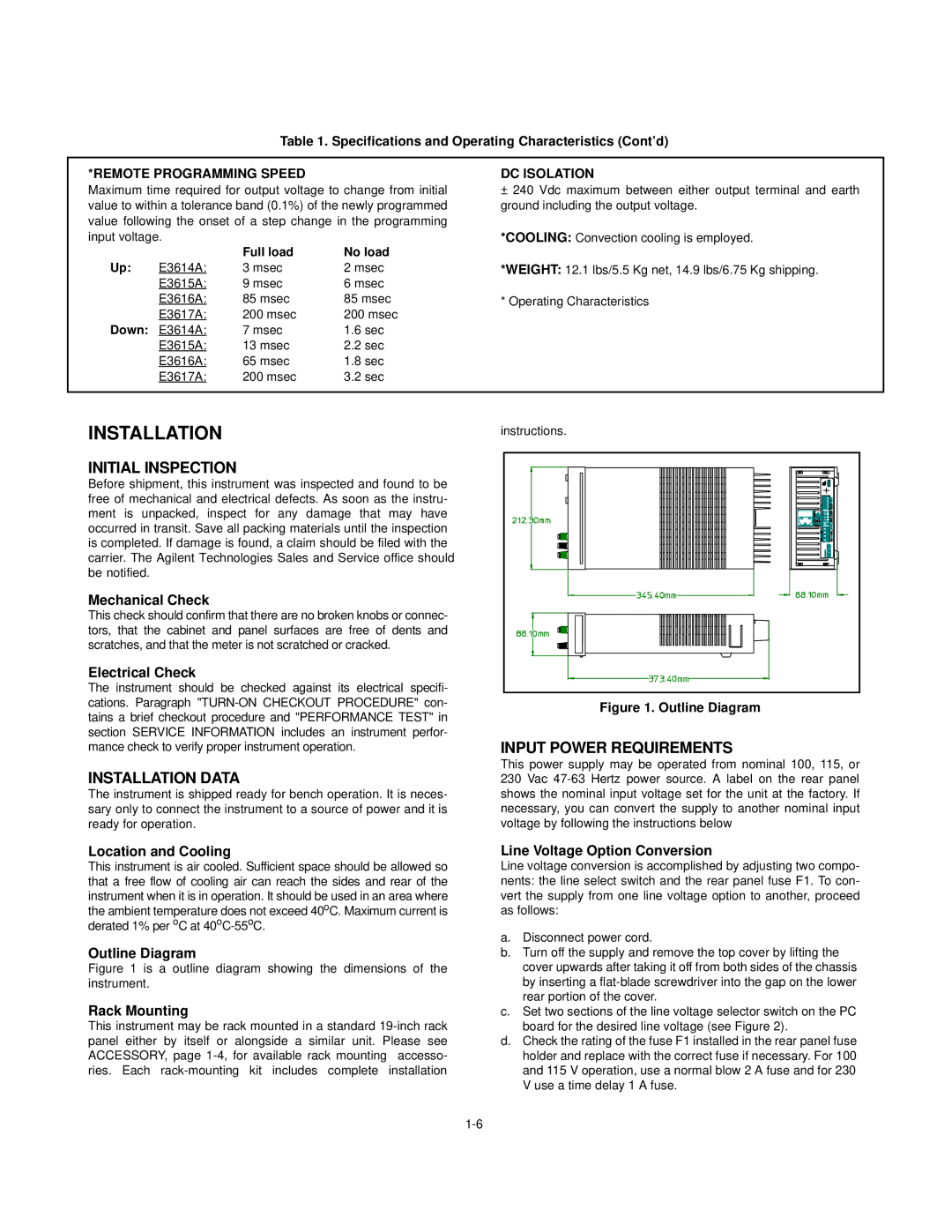

Figure 1. Outline Diagram

INPUT POWER REQUIREMENTS

This power supply may be operated from nominal 100, 115, or 230 Vac

Location and Cooling

This instrument is air cooled. Sufficient space should be allowed so that a free flow of cooling air can reach the sides and rear of the instrument when it is in operation. It should be used in an area where the ambient temperature does not exceed 40oC. Maximum current is derated 1% per oC at

Outline Diagram

Figure 1 is a outline diagram showing the dimensions of the instrument.

Rack Mounting

This instrument may be rack mounted in a standard

Line Voltage Option Conversion

Line voltage conversion is accomplished by adjusting two compo- nents: the line select switch and the rear panel fuse F1. To con- vert the supply from one line voltage option to another, proceed as follows:

a.Disconnect power cord.

b.Turn off the supply and remove the top cover by lifting the cover upwards after taking it off from both sides of the chassis by inserting a

c.Set two sections of the line voltage selector switch on the PC board for the desired line voltage (see Figure 2).

d.Check the rating of the fuse F1 installed in the rear panel fuse holder and replace with the correct fuse if necessary. For 100 and 115 V operation, use a normal blow 2 A fuse and for 230 V use a time delay 1 A fuse.