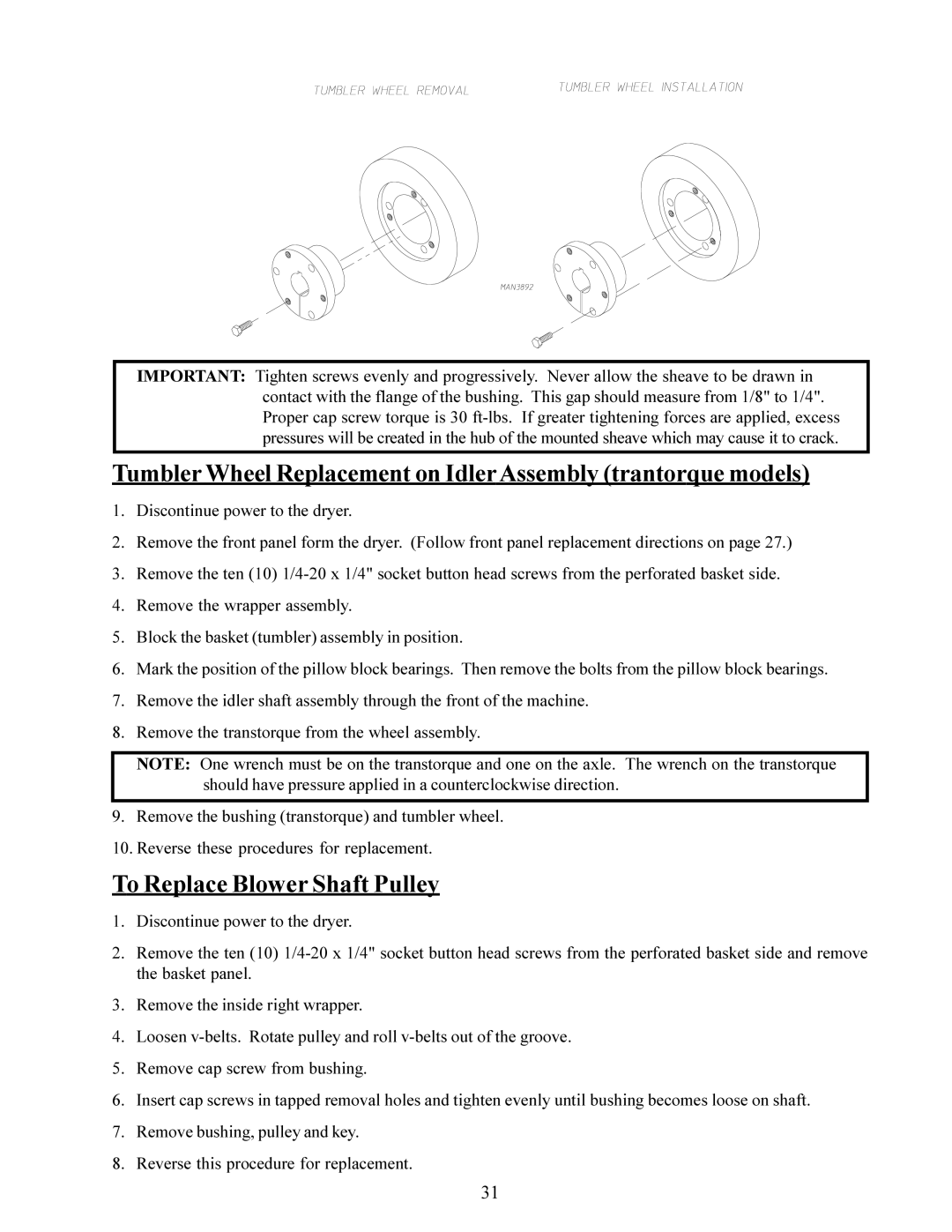

IMPORTANT: Tighten screws evenly and progressively. Never allow the sheave to be drawn in contact with the flange of the bushing. This gap should measure from 1/8" to 1/4". Proper cap screw torque is 30

Tumbler Wheel Replacement on IdlerAssembly (trantorque models)

1.Discontinue power to the dryer.

2.Remove the front panel form the dryer. (Follow front panel replacement directions on page 27.)

3.Remove the ten (10)

4.Remove the wrapper assembly.

5.Block the basket (tumbler) assembly in position.

6.Mark the position of the pillow block bearings. Then remove the bolts from the pillow block bearings.

7.Remove the idler shaft assembly through the front of the machine.

8.Remove the transtorque from the wheel assembly.

NOTE: One wrench must be on the transtorque and one on the axle. The wrench on the transtorque should have pressure applied in a counterclockwise direction.

9.Remove the bushing (transtorque) and tumbler wheel.

10.Reverse these procedures for replacement.

To Replace Blower Shaft Pulley

1.Discontinue power to the dryer.

2.Remove the ten (10)

3.Remove the inside right wrapper.

4.Loosen

5.Remove cap screw from bushing.

6.Insert cap screws in tapped removal holes and tighten evenly until bushing becomes loose on shaft.

7.Remove bushing, pulley and key.

8.Reverse this procedure for replacement.

31