134200, 137200, 133200, 136200, 135200 specifications

The Briggs & Stratton 136200 is a powerful and reliable small engine that is engineered to deliver exceptional performance and durability for a variety of applications. This versatile engine is a popular choice among outdoor power equipment manufacturers due to its robust features and advanced technologies.One of the standout characteristics of the Briggs & Stratton 136200 is its 5.5 horsepower output, which is capable of powering lawn mowers, pressure washers, and other equipment. The engine operates with a displacement of 142cc, providing a great balance between power and fuel efficiency. Users can expect a long service life, thanks to the engine's rugged construction and high-quality materials.

The engine features a reliable overhead valve (OHV) design, which enhances fuel efficiency while optimizing the combustion process. This design contributes to lower emissions, making the Briggs & Stratton 136200 environmentally friendly. The OHV configuration also provides improved thermal regulation, resulting in better performance in various operating conditions.

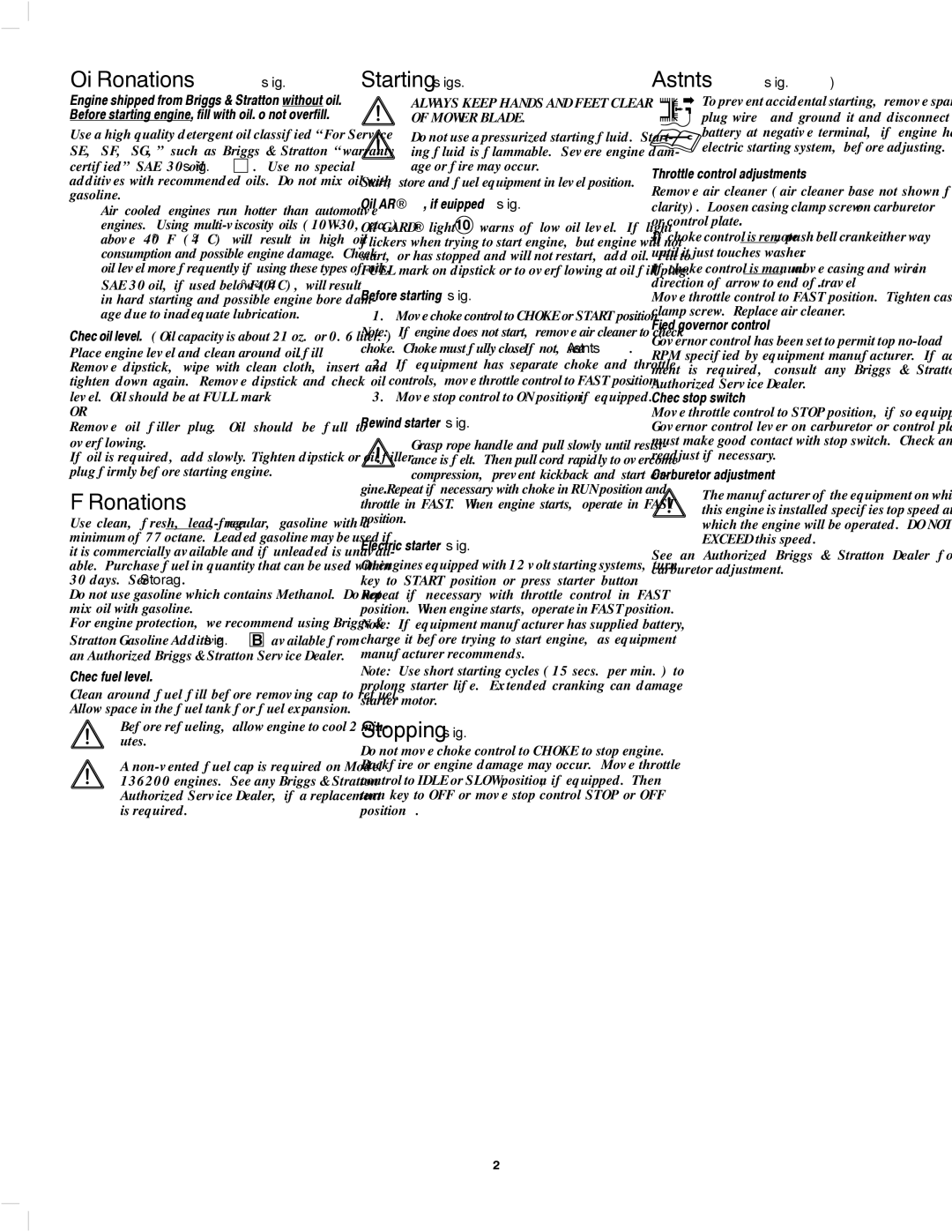

Equipped with a ReadyStart system, the engine simplifies starting. This technology eliminates the need for a manual choke, allowing for effortless starting even in cold weather. Users appreciate the convenience of the automatic primer system, which ensures the correct amount of fuel reaches the combustion chamber with minimal effort.

Another key feature of the Briggs & Stratton 136200 is its low oil shutdown mechanism. This safety feature automatically stops the engine when the oil level becomes too low, preventing potential damage and prolonging the engine's lifespan. Additionally, the engine is designed for easy maintenance, with easily accessible components that allow for quick oil changes and tune-ups.

Furthermore, the built-in dual air cleaner system enhances filtration and ensures the engine operates smoothly, regardless of the dust and debris in the environment. This attention to air quality contributes to improved overall engine performance and longevity.

In summary, the Briggs & Stratton 136200 is a well-engineered small engine that combines power, efficiency, and convenience, making it an excellent choice for various outdoor equipment applications. Its advanced technologies, user-friendly features, and durable design position it as a trusted option for both manufacturers and end-users alike. Whether for residential lawn care or commercial cleaning tasks, the 136200 continues to prove its worth in the field.