Please read this manual before making any adjustments

SERVICE MANUAL

BAS-311E,311EL

BAS-326E,326EL

z Safety indications and their meanings

Symbols

DANGER

Indications

Sewing

x Notes on safety

Installation

Cleaning

Maintenance and inspection

c Warning labels

Safety devices Thread take-up cover Eye guard, Belt cover

Finger guard, etc

Moving parts may cause injury

Explanation of models

INDEX

Chapter 4. Adjustments

Chapter 5. How to make up the work clamp

Chapter 1. Mechanical description

Chapter 1. Mechanical description

1. Needle bar, thread take-up, lower shaft and shuttle hook mechanism

2. Work clamp lifting mechanism 1 Solenoid type, 311E

e r q w t y u

Work clamp lifting mechanism 2 311E, 311EL Pneumatictype

Work clamp lifting mechanism 326E

w e q r

w eq r

u i y o

3. Feed mechanism X axis 311E, 311EL, 326E, 326EL

e r w

Feed mechanism Y axis 311E and 311EL

Feed mechanism Y axis 326E, 326EL

ey q

q w i r e t

4. Presser foot mechanism

r t e q w y u

Presser foot mechanism

e r q w

5. Thread trimmer mechanism

t yu i o

6. Thread nipper 1 when presser foot rises

Thread nipper 2 during thread trimming

r r e q w

q w e t y r

7. Thread wiper 1 vertical wiper standard

Thread wiper 2 horizontal wiper optional

q w e r t

q w e r

Chapter 2. Disassembly

1. Covers 1 311E

Chapter 2. Disassembly

q w r y e u t

Covers 2 311EL

Covers 3 326E, 326EL

q !1 e i y u o

w u o

2. Feed mechanism

t y r q w

2. Remove the bolt and the work clamp r

3. Remove the screw, the feed plate t and the needle sub plate y

3. Presser foot mechanism

w q u y e

4. Needle bar mechanism

t r o i

e y r u w

7 !6 y

5. Upper shaft mechanism

wt y ru o i e!0 q

r !7

5q !2 !1 6r !4

6. Feed mechanism Y axis 1 311E and 311EL

w q e r t

1. Loosen the set screw and remove the X-feed shaft q

2. Remove the screws and the work clamp arm w

Feed mechanism Y axis

q r t

Feed mechanism Y axis 3 326E, 326E

r w e q u q i t y

7. Feed mechanism X axis 1 311E

r y w e

Feed mechanism X axis 2 311EL and 326E, 326EL

@3 o 0!1 6 !2!3

u r q

@2 @0

1!0 o i

8. Lower shaft mechanism

w r q e

9. Work clamp lifter Solenoid type

i t q r

10. Thread nipper mechanism

r u r t y i e w q t r y o

@0!3 !7

11. Thread trimmer mechanism

@2 t

Chapter 3. Assembly

1. Thread trimmer mechanism

Chapter 3. Assembly

t y r e

2. Thread nipper mechanism

i 0 !1

work clamp lifter wire @1, and tighten the bolt @2

4 !5

u @2 y @4 !4 t

3. Work clamp lifter mechanism

o !1

Sliding portions of link shaft C q and link B w

u r y t e i u w q

e w q

2 !3

4. Feed mechanism X axis 311E

e q w r

Adjustment procedure

Feed mechanism X axis 311EL, 326E

w !5

i u

t 0i y

o @7

Feed mechanism X axis 311EL and 326E

@0 w

e 1!0

t r qty o

r !2

q 1w

@9 #2 @8 #0 @3

@0 @2

#1 @4 @5

@6 !6

Feed mechanism Y axis 326E

r q w e

5. Temporarily attach the work clamp Arm !2to the Y-feed bracket i using the bolts and washers

q w i

6. Upper shaft mechanism

e q w t y r e q

3!4 u i o

7. Needle bar mechanism

q !5

8. Presser foot mechanism

o 0 !4

@3 w

q 1!4

w @1

9. Lower shaft mechanism

w q e t o u 0y

10. Lower shaft Rotary hook

r r e o !0

t o e y i q u

i !0

r e t w q i u y !1 o

2. Secure the needle sub plate e with the screw r

12.Press the P key and adjust the X-sensor setting plate !7so that the needle !4is aligned with the home position X=0, Y=0 of the H-position standard plate !1

Feed guide mechanism Home position adjustment Y 311E and 311EL

Feed guide mechanism Home position adjustment Y 326E and 326EL

qt w

P key

13. Covers 311E

e q

o !0

@1 @0 @2

311EL

326E · 326EL

y w e i u t

o t !1

Chapter 4. Adjustments

1. Adjusting the needle bar height adjustment

2. Adjusting the needle bar lift amount

Chapter 4. Adjustments

3. Adjusting the needle clearance

4. Adjusting the driver needle guard

5. Adjusting the shuttle race thread guide

q w e

6. Adjusting the two-step work clamp lift amount

6-1. Solenoid type

6-2. Pneumatic type

rr q

yw w r

BAS-311E · 311EL

7. Adjusting the movable knife

7-1. Replacing the movable and fixed knives

u w q

A. After the movable knife and fixed knife are properly engaged, tighten shoulder screw

311E, 311EL

326E, 326EL

r q t

8. Adjusting the lowest point of the presser foot

w o e y

8-1. Presser foot adjustment

9. Changing the presser foot lift

r e q w w

q e

10. Wiper adjustment

For vertical wiper standard

For horizontal wiper optional

re y t q w

11. Adjusting the home position

X axis

Y axis 311E and 311EL

e r e r

Y axis 326E, 326EL

12. Adjusting the tension of the timing belt

Adjusting the tension of X-timing belt 311E

Adjusting the tension of Y-timing belt

e w r

Adjusting the tension of X-timing belt B326

311EL and 326E, 326EL

Adjusting the tension of X-timing belt A326

Y-axis feed

13. Adjusting backlashes

Lower shaft

Most 0.15 mm

14. Adjusting the driving lever stopper position

15. Adjusting the thread trimmer driving lever position

17. Adjusting the presser foot height

16. Work clamp lift components for manual operation Sole- noid type

q q w

y t r

18. Adjusting the needle up stop position

wu y

Chapter 5. How to make up the work clamp

1. How to make up clamping type work clamp

How to make up the work clamp

How to make up the feed plate

2. How to make up cassette type work clamp

How to make up the plastic work clamp

Cassette presser

Clamp spring

Chapter 6 Power supply and electrical parts adjustment

1. Precautions at the time of adjustment

2. Components inside the control box

Power supply circuit board

3. Fuse explanation

4. Connectors

Connector positions Outside of the control box

Outside of the panel Panel circuit board

Programmer and programmer circuit board

LCD contrast VR

2. Work clamp lifter and thread trimmer mechanisms

Contact failure

1. Feed mechanism

Power

Power switch

3. Sewing operation

supply circuit

DC fan

4. Programmer operation

5. Others

Error E.40 appears

Error E.12 appears

Emergency stop switch is rejected

DIP switch A

5. DIP switches

Panel DIP switch functions

DIP switch B

DIP switches inside the control box

DIP switch C

DIP switch D

6. Changing special functions using the memory switches

BAS-300E series

メニュー

MENU

Memory Switches 00 - 0F

Memory Switches 20 - 2F

Memory Switches 10 - 1F

Chapter 6 Power supply and electrical parts adjustment

OFF OFF

7. Checking the input sensor and DIP switch input

BAS-300E series

9. Clearing all memory settings

8. Checking the input voltage

X-SCALE

R / W

10. Confirming software version

Version number indication example

BAS-300E series

Program NO display

11. Error codes

Error codes E.9 * - E.F

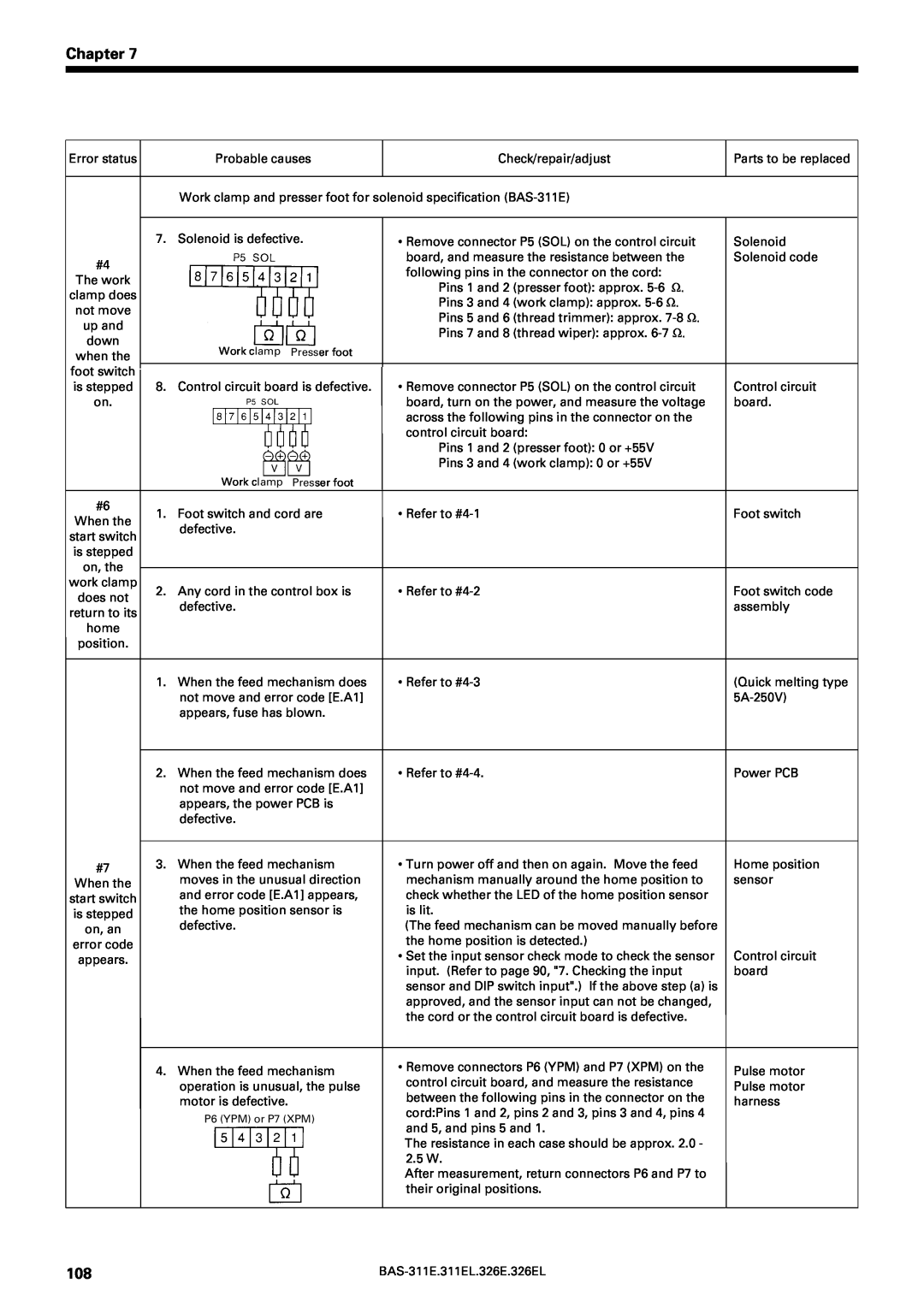

Chapter 7. Trouble shooting

Flowchart

Explanation of shapes

Chapter

off?

work clamp

Chapter

Is the TEST

Chapter

needle at the upper position when NO

stops?

Does the

machine stop with the

Before adjustment

Problem solution and measures

Precautions

V, 380 V, 400 V, and

For 200 V, 220 V, and

For 100 V, 110 V

Chapter

Chapter

#1.2

switches

pressed

After a few

Presser

Chapter

Chapter

switch is

occurs

cannot sew

Chapter

S51037326LA-001

Chapter 8. 1. Gauge parts list according to subclasses

S51038326LB-001

Chapter 9. Gauge parts list

Chapter 9. Gauge parts list

Presser foot

Needle hole plate

Work clamp, Feed plate BAS-311E

OPTION PARTS

Feed plate blank and Work clamp blank BAS-311E

Work clamp and Feed plate BAS-311EL

Feed plate blank and Work clamp blank BAS-311EL

Feed mechanism BAS-326E

Feed mechanism Option parts BAS-326E

Feed mechanism BAS-326E, 326EL

For one-touch work clamp plate assy

Feed mechanism Option parts

Feed mechanism Option parts BAS-326E,326EL

BAS-311E.311EL.326E.326EL

Chapter 10. Option parts

Chapter 10. Option parts

Programmer assy Inner clamp device One-touch clamping device

Milling device WP stitch device Auto bobbin changer

Programmer

Inner clamping device Option device

A45254000

Inner clamping device Option device BAS-326EL

For Supplry parts

For change the feed plate setting position

One-touch work clamp

S20822101

S20289101

One-touch work clamp Option parts BAS-326EL

Snap fastener and hook attachment device

M-508K

M-520K

M-525K

For sewing the belt with hook

S24621-101

S24628-101

S18598-001

S18606-001

Wide perfect device

Needle cooler set

Soft work clamp set

Play prevention work clamp

For Horizontal Wiper

Thread wiper set Pneumatic type

2-step tension device

Auxiliary device

Chapter 10. Option parts

Control Block Diagram

Presser toot

Yellow

Brown

Convertion

Orange

per shaft mo

SERVICE MANUAL

Printed in Japan

151-V11, V12

I9080764 1999. 08. B