FEATURES/BENEFITS

580D036-072 579F180,216 580D090-150 579F240,300

Page

Table of Contents

Model Number Nomenclature

580D036-150 Models only

Model Number Nomenclature 579F180-300 Models only

ARI* Capacity Ratings

Heating Capacities and Efficiencies Ð 579F180-300

ARI* Capacity Ratings

Heating Capacities and Efficiencies Ð 580D036-150

Rise Efficiency

Physical Data Ð 580D036-072

Unit Size 580D

Physical Data Ð 580D036-072

Unit Size 580D Medium LOW/MEDIUM High Heat

Quantity...Diameter Motor Hp...Rpm

Physical Data Ð 580D090-150

090 102 120 150 Nominal Capacity tons

Pulley Center Line Distance Std

Physical Data Ð 580D090-150

Unit Size 580D LOW/MEDIUM High Heat Hihg Heat Medium Heat

Physical Data Ð 579F180-300

Unit Size 579F

LOW/HIGH Heat

Physical Data Ð 579F180-300

Unit Size 579F

Head Pressure Control

Options and Accessories

Option ACCESSORY²

Head Pressure Control Speed Control 180,216

Durablade Economizer

Options and Accessories

Time Guard II Control

Sizes

Only

Power Exhaust 180-300 Shown Accusensor Sensor

Accusensor Control

Thermostat

Base Unit Dimensions Ð 580D036-072

Unit

Base Unit Dimensions Ð 580D090-150

Unit Corner Weight Dimensions

Base Unit Dimensions Ð 579F180,216

486 220 636 288

Base Unit Dimensions Ð 579F240,300

Dimension

Accessory Dimensions

Roof Curb Ð 580D036-072

Accessory Dimensions

Roof Curb Ð 580D090-150

Unit DEG

Dimensions degrees and inches

PKG. NO. REF Curb Description Height

579F

Accessory Curb Description Package no Height

Horizontal Supply/Return Adapter Installation 579F180-300

Power Exhaust 579F180-300

Pre-Assembled, High Static

Selection Procedure with 579F180 example

II Select Unit Based on Required Cooling Capacity

Performance Data Cooling Capacities

SHC

Performance Data

Cooling Capacities

580D150 121¤2 Tons

Performance Data Cooling Capacities

580D120 10 Tons

579F216 18 Tons

579F180 15 Tons Temp F Air Entering Evaporator Ð Cfm/BF

4500/0.08 5250/0.10 6000/0.11 6750/0.12 7500/0.14 Condenser

5400/0.06 6000/0.07 7200/0.08 9000/0.09

7000/0.03 8750/0.05 10,000/0.07 11,250/0.09

579F240 20 Tons Temp F Air Entering Evaporator Ð Cfm/BF

579F300 25 Tons

Fiop

FAN Performance Ð 580D036-150 Vertical Discharge Units

580D036 3 Tons Ð Standard Motor Direct Drive

580D036 3 Tons Ð Alternate Motor Belt Drive

580D048 4 Tons Ð Standard Motor Direct Drive

580D048 4 Tons Ð Alternate Motor Belt Drive

580D060 5 Tons Ð Standard Motor Direct Drive

580D060 5 Tons Ð Alternate Motor Belt Drive

2600

580D072 6 Tons Air¯ow External Static Pressure in. wg

Rpm Bhp Watts 1800

1562

2550

580D090 71¤2 Tons Air¯ow External Static Pressure in. wg

Rpm Bhp Watts 2250

3100

891 2188 3300

580D102 81¤2 Tons Air¯ow External Static Pressure in. wg

Rpm Bhp Watts 2550

904 2300 3400

4300

580D120 10 Tons Air¯ow External Static Pressure in. wg

Rpm Bhp Watts 3000

985

5100

580D150 121¤2 Tons Air¯ow External Static Pressure in. wg

Rpm Bhp Watts 3750

5200

FAN Performance Ð 580D036-150 Horizontal Discharge Units

299 761 357 859 483 901 546 943 609 1300 604 231 673

1989 1466 2171 Bhp Brake Horsepower Input to Fan

Rpm Bhp Watts 1200 569 189 641

352 788 410 887 546 928 615 968 683 1400 640 284 705

1365 2038 1426

Medium Speed High Speed 208 230, 460, 575 230,460, 575

1392

1331 1986 1400 2227 1461

1496 2240 1529

1536

1514

1603

882

997 3055 1040 3333 Bhp Brake Horsepower Input to Fan

894

895

783

1062 3676 1102 3860 Bhp Brake Horsepower Input to Fan

Rpm Bhp Watts 2550 669 627 867 692 1056 754

812

973

962

1008

1019

1178

Bhp Watts 3750

1166

1131

FAN Performance Ð 579F180-300 Units

Performance Data FAN Performance Ð 579F180-300 Units

Rpm Bhp Watts 6000

10,000 Bhp Brake Horsepower Input to Fan

579F240 20 Tons Air¯ow External Static Pressure in. wg

9500

Rpm Bhp Watts 500

10,500 11,000 11,250 Bhp Brake Horsepower Input to Fan

579F300 25 Tons Air¯ow

3507

AIR Quantity Limits

Sound Power Total Unit

Sound Weighted Octave Bands Unit Rating

Unit Minimum CFM Maximum CFM

Component CFM

ACCESSORY/FIOP Static PRESSURE* in. wg − 580D090-150

ACCESSORY/FIOP Static PRESSURE* in. wg − 579F180-300

Unit Motor Pulley Turns Open

Nominal Input

Altitude COMPENSATION* Ð

Btuh Nominal

Input

EVAPORATOR-FAN Motor Efficiency

Fan Performance Using Accessory Power Exhaust 579F180-300

Altitude COMPENSATION* Ð 580D090-150

Altitude Derating FACTOR* Ð ALL Units

Continuous Operating AMP Draw BHP

EVAPORATOR-FAN Motor Performance

Maximum Unit EVAPORATOR-FAN Acceptable

580D036

Electrical Data Ð 580D036-150

RLA LRA FLA MCA MOCP²

Electrical Data Ð 579F180-300

Horizontal Discharge Ducting

Typical Piping and Wiring Ð 580D036-150

Vertical Discharge Ducting

NEC Ð National Electrical Code

Typical Piping and Wiring Ð 579F180-300

579F180 shown

Typical Wiring Schematic Ð 580D036-150

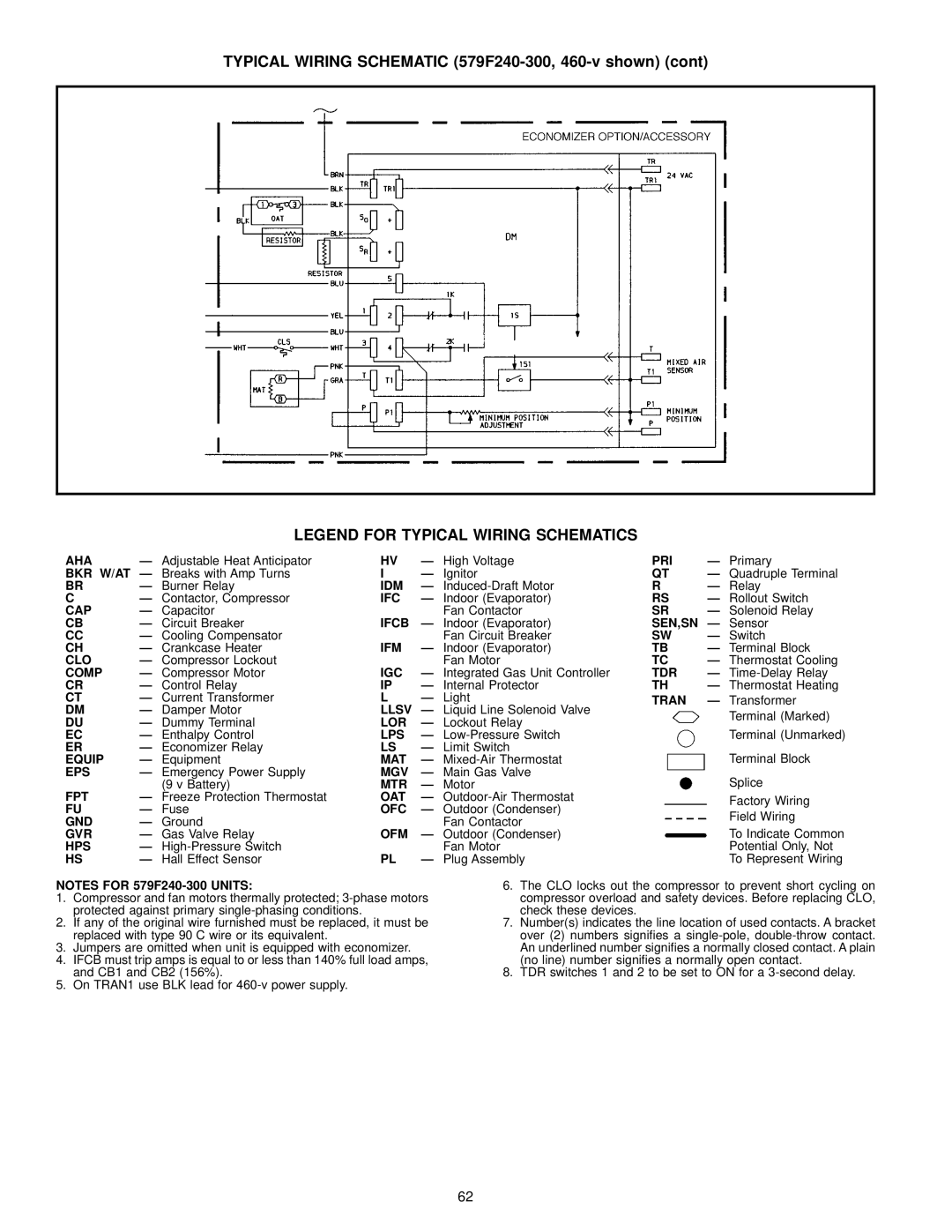

Typical Wiring Schematic 579F240-300, 460-v shown

IDM

AHA

PRI

IFC

Controls

Operating Sequence

Controls

Cooling, Units With Parablade Economizer 580D036-072

Application Data

580D036-150

Application Data

Guide Specifications Ð 580D036-150

Part 1 Ð General

Guide Specifications Ð 580D036-150

Guide Specifications Ð 580D036-150

Guide Specifications Ð 579F180-300

Guide Specifications Ð 579F180-300

Copyright 1998 Bryant Heating & Cooling Systems