Installation, Start-Upand Service Instructions

CONTENTS

SAFETY CONSIDERATIONS

GENERAL

MAJOR SYSTEM COMPONENTS Constant Volume CV Units

a50-7257ef

INSTALLATION

Step 1 - Complete Pre-InstallationChecks

Table 2 - Modular Unit Shipping Table

Fig. 2 - 50BVC,J,Q020-034Dimensions

Fig. 3 - 50BVE,K020-034Dimensions

a50-8201

Fig. 4 - 50BVT,V,W034 High-BoyDimensions

Fig. 5 - 50BVT,V,W034 Low-BoyDimensions

Fig. 6 - 50BVT,V,W044-064 High-BoyDimensions

Fig. 7 - 50BVT,V,W044-064 Low-BoyDimensions

Fig. 8 - 50BVU,X034 High-BoyDimensions

Fig. 9 - 50BVU,X034 Low-BoyDimensions

Fig. 10 - 50BVU,X044-064 High-BoyDimensions

Fig. 11 - 50BVU,X044-064 Low-BoyDimensions

a50-7306ef

NOTES 1.Dimensions in inches mm

a50-7307ef

NOTES 1.Dimensions in inches mm

Shipping Weights lb

a50-8235

Size 034 Units Size 044-064Units

Table 3A - Physical Data - 50BVC,E,J,K,Q

Table 3B - Physical Data - 50BVT,U,V,W,X

Multiple Fan Units

Fig. 15 - Typical Fan Discharge Connections for

a50-7267ef

a50-7138ef

Fig. 16 - Duct Static Pressure Probe

P/N 39EK20462

Fig. 18 - DHS Pressure Limit Location

Fig. 19 - DHS Limit Switch P/N

Step 4 - Make Piping Connections

a50-8253

50BVT,V,W Units

Table 5A - Condenser Pressure Drop

50BVC,J,Q Units

Table 5B - Condenser Pressure Drop

50BVT,U,V,W,X Units

Table 6A - Hot Water Pressure Drop

50BVC,E,J,K,Q Units

Table 6B - Hot Water Pressure Drop

a50-7270ef

Step 5 - Complete Electrical Connections

Table 7B - Economizer Pressure Drop Curve

ft wg, 50BVT,U,V,W,X Units

Table 9A - Electrical Data - 50BVC,E,J,K,Q

Table 9B - Electrical Data - 50BVT,U,V,W,X

Fig. 24 - Typical Wiring 18 to 30 Ton Units

a50-7272ef

Two-StageCooling Units

Fig. 26 - Field Terminal Block

a50-7273ef

Table 10 - Recommended Cables

a50-7164tf

a39-1867t

Installation Unit Discharge Location

a50-7275ef

Fig. 27 - Modular Unit VAV Control Panel

10 Kilo- ohm

START-UP

Table 11 - Thermistor Resistance vs Temperature

Values for Supply-AirTemperature Sensor

Table 13 - Fan Performance - 50BVC,E,Q020

CV Unit Start-Up

Table 14 - Fan Performance - 50BVC,E,Q024

Table 15 - Fan Performance - 50BVC,E,Q028

Table 16 - Fan Performance - 50BVC,E,Q034

Table 17 - Fan Performance - 50BVT,U,V034

Table 17 - Fan Performance - 50BVT,U,V034 cont

Table 18 - Fan Performance - 50BVT,U,V044

Table 19 - Fan Performance - 50BVT,U,V054

Table 19 - Fan Performance - 50BVT,U,V054 cont

Table 20 - Fan Performance - 50BVT,U,V064

Table 20 - Fan Performance - 50BVT,U,V064 cont

VAV Unit Start-Up

a50-7425ef

OMNIZONE VPAC

02-06-04

Fig. 32 - LID

Fig. 33 - 50BV VFD Display

The LID display will show Year

Table 21 - Controller Set Points

Table 22 - Controller Hardware Points

Table 23 - Software Points

Table 24 - Configuration Parameters

Unoccupied space or return air temperature demand

MAINTENANCE

SERVICE

Fig. 35 - Forced Circulation Method

a50-186tf

Fig. 34 - Gravity Flow Method

a50-187tf

a50-7135tf

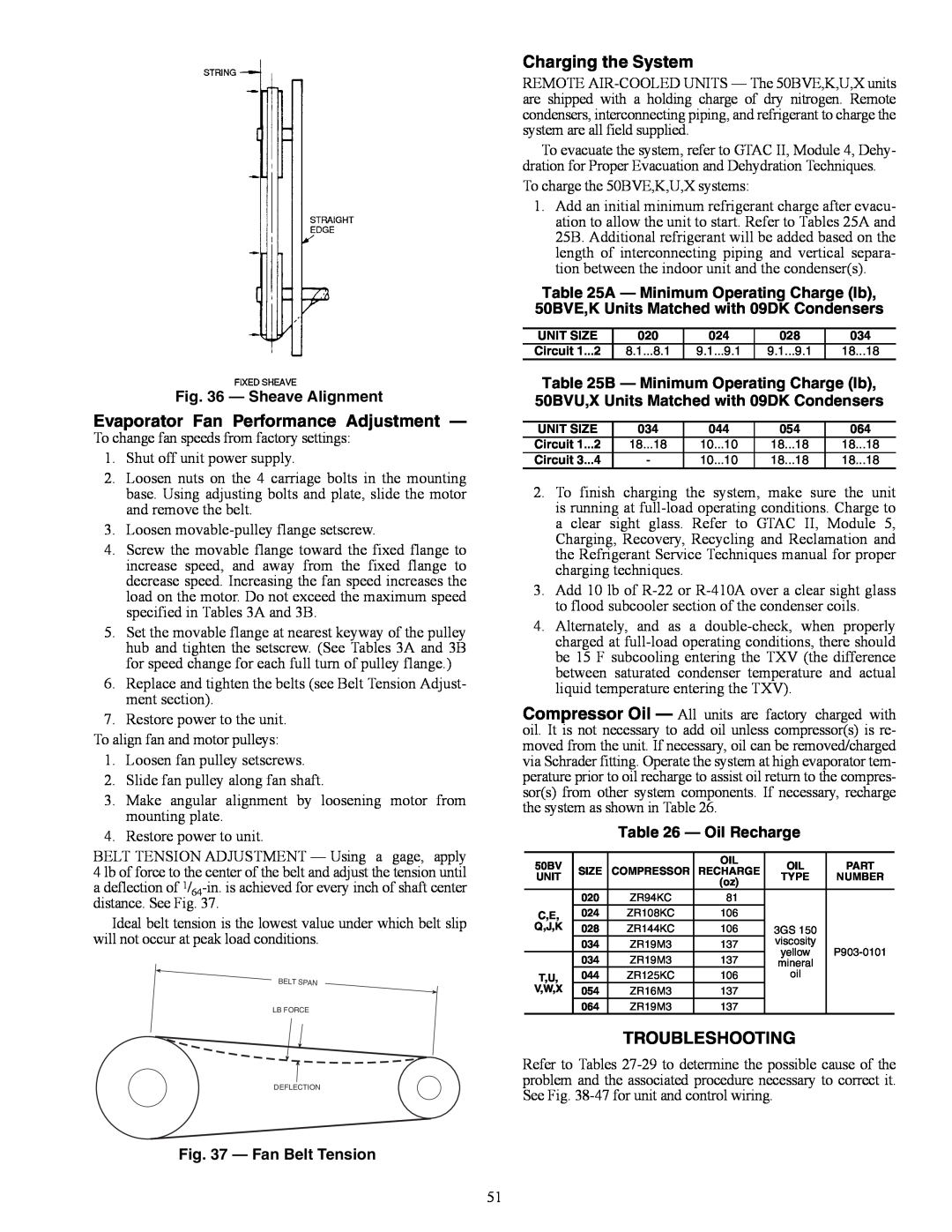

Evaporator Fan Performance Adjustment

TROUBLESHOOTING

Charging the System

POSSIBLE CAUSE

PROBLEM

POSSIBLE CAUSE

Table 28 - Unit Troubleshooting

PROBLEM

CORRECTION PROCEDURE

Table 29 - CV Units LED Diagnostic Codes

Table 30 - Forcing an Input or Output

Table 31 - Clearing a Forced Input or Output

Page

Page

Page

Page

UNIT WIRING

FIELD WIRING

Page

TRANS-1

FIELD WIRING

WIRE LEGEND

a50-7282ef

PCB2 J1

FIELD WIRING

FIELD WIRING

UNIT WIRING

PCB1

PCB1

FIELD WIRING

LEGEND AND NOTES FOR FIG

10-08

Copyright 2008 Carrier Corporation

Catalog No

Form 50BV-3SI

CONTROLS

START-UPCHECKLIST

I. PRELIMINARY INFORMATION

II. PRE-START-UP

III.START-UP