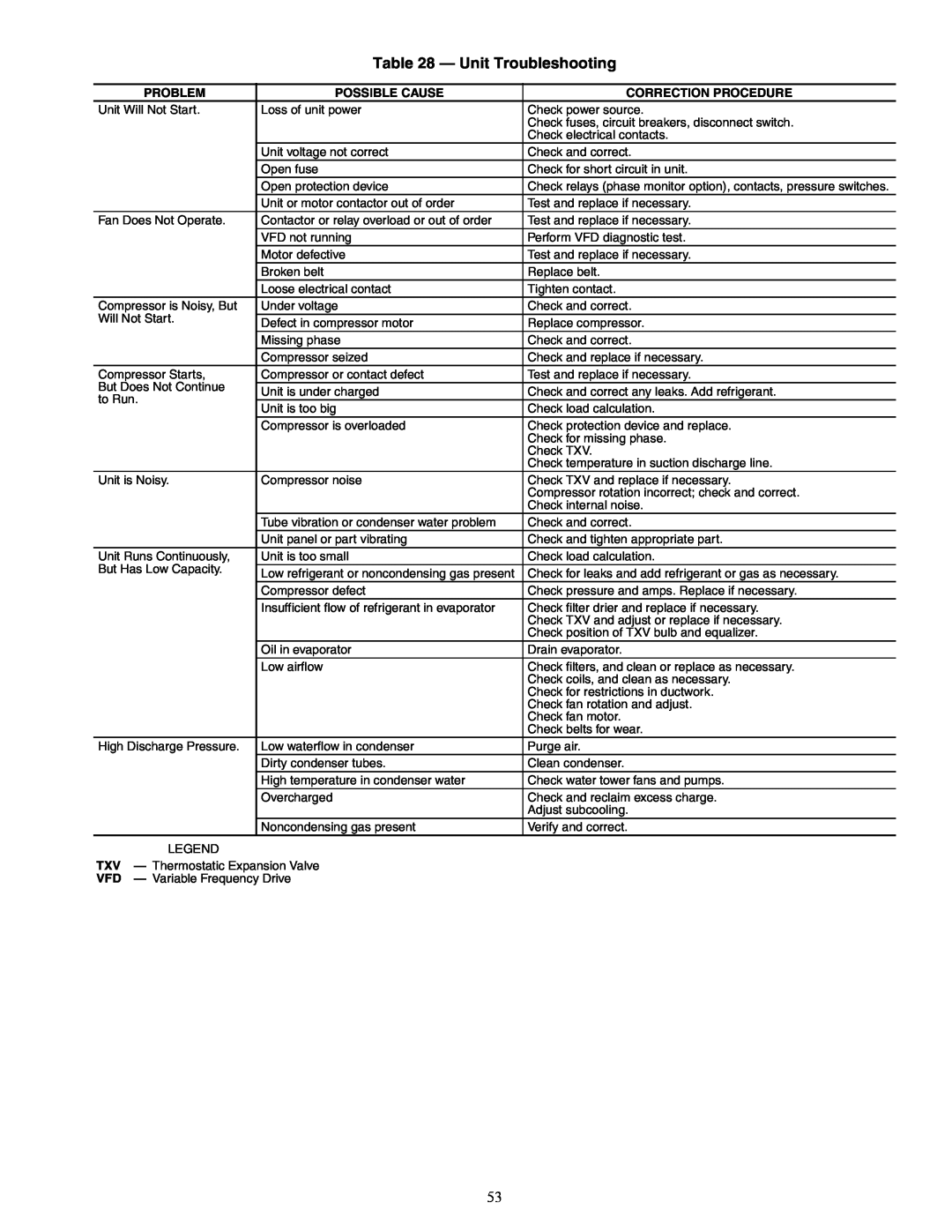

Table 28 — Unit Troubleshooting

PROBLEM | POSSIBLE CAUSE | CORRECTION PROCEDURE | |

Unit Will Not Start. | Loss of unit power | Check power source. | |

|

| Check fuses, circuit breakers, disconnect switch. | |

|

| Check electrical contacts. | |

| Unit voltage not correct | Check and correct. | |

| Open fuse | Check for short circuit in unit. | |

| Open protection device | Check relays (phase monitor option), contacts, pressure switches. | |

| Unit or motor contactor out of order | Test and replace if necessary. | |

Fan Does Not Operate. | Contactor or relay overload or out of order | Test and replace if necessary. | |

| VFD not running | Perform VFD diagnostic test. | |

| Motor defective | Test and replace if necessary. | |

| Broken belt | Replace belt. | |

| Loose electrical contact | Tighten contact. | |

Compressor is Noisy, But | Under voltage | Check and correct. | |

Will Not Start. |

|

| |

Defect in compressor motor | Replace compressor. | ||

| |||

| Missing phase | Check and correct. | |

| Compressor seized | Check and replace if necessary. | |

Compressor Starts, | Compressor or contact defect | Test and replace if necessary. | |

But Does Not Continue |

|

| |

Unit is under charged | Check and correct any leaks. Add refrigerant. | ||

to Run. | |||

Unit is too big | Check load calculation. | ||

| |||

| Compressor is overloaded | Check protection device and replace. | |

|

| Check for missing phase. | |

|

| Check TXV. | |

|

| Check temperature in suction discharge line. | |

Unit is Noisy. | Compressor noise | Check TXV and replace if necessary. | |

|

| Compressor rotation incorrect; check and correct. | |

|

| Check internal noise. | |

| Tube vibration or condenser water problem | Check and correct. | |

| Unit panel or part vibrating | Check and tighten appropriate part. | |

Unit Runs Continuously, | Unit is too small | Check load calculation. | |

But Has Low Capacity. |

|

| |

Low refrigerant or noncondensing gas present | Check for leaks and add refrigerant or gas as necessary. | ||

| |||

| Compressor defect | Check pressure and amps. Replace if necessary. | |

| Insufficient flow of refrigerant in evaporator | Check filter drier and replace if necessary. | |

|

| Check TXV and adjust or replace if necessary. | |

|

| Check position of TXV bulb and equalizer. | |

| Oil in evaporator | Drain evaporator. | |

| Low airflow | Check filters, and clean or replace as necessary. | |

|

| Check coils, and clean as necessary. | |

|

| Check for restrictions in ductwork. | |

|

| Check fan rotation and adjust. | |

|

| Check fan motor. | |

|

| Check belts for wear. | |

High Discharge Pressure. | Low waterflow in condenser | Purge air. | |

| Dirty condenser tubes. | Clean condenser. | |

| High temperature in condenser water | Check water tower fans and pumps. | |

| Overcharged | Check and reclaim excess charge. | |

|

| Adjust subcooling. | |

| Noncondensing gas present | Verify and correct. | |

LEGEND |

|

|

TXV — Thermostatic Expansion Valve

VFD — Variable Frequency Drive

53