11.Check supply fan belts, sheaves, and bearings. Check the lubrication of the fan and motor bearings. Check bear- ing and bearing set screws for tightness. Check sheave alignment and belt tension. Hand turn fan to ensure fan wheel does not rub on housing. The fan shaft and motor shaft must turn freely before power is applied to the unit.

12.Check exhaust fan belts, sheaves, and bearings. Check the lubrication of the fan and motor bearings. Check bear- ing and bearing set screws for tightness. Check sheave alignment and belt tension. Hand turn fan to ensure fan wheel does not rub on housing.

13.Check economizer linkage. Economizer dampers should be fully closed. Linkage should permit full and free travel.

14.Check that the correct return air ®lters are installed in the ®lter tracks. Do not operate unit without return air ®lters.

15.Check that all access doors on the air handler section have been closed and secured.

16.Fan motors are

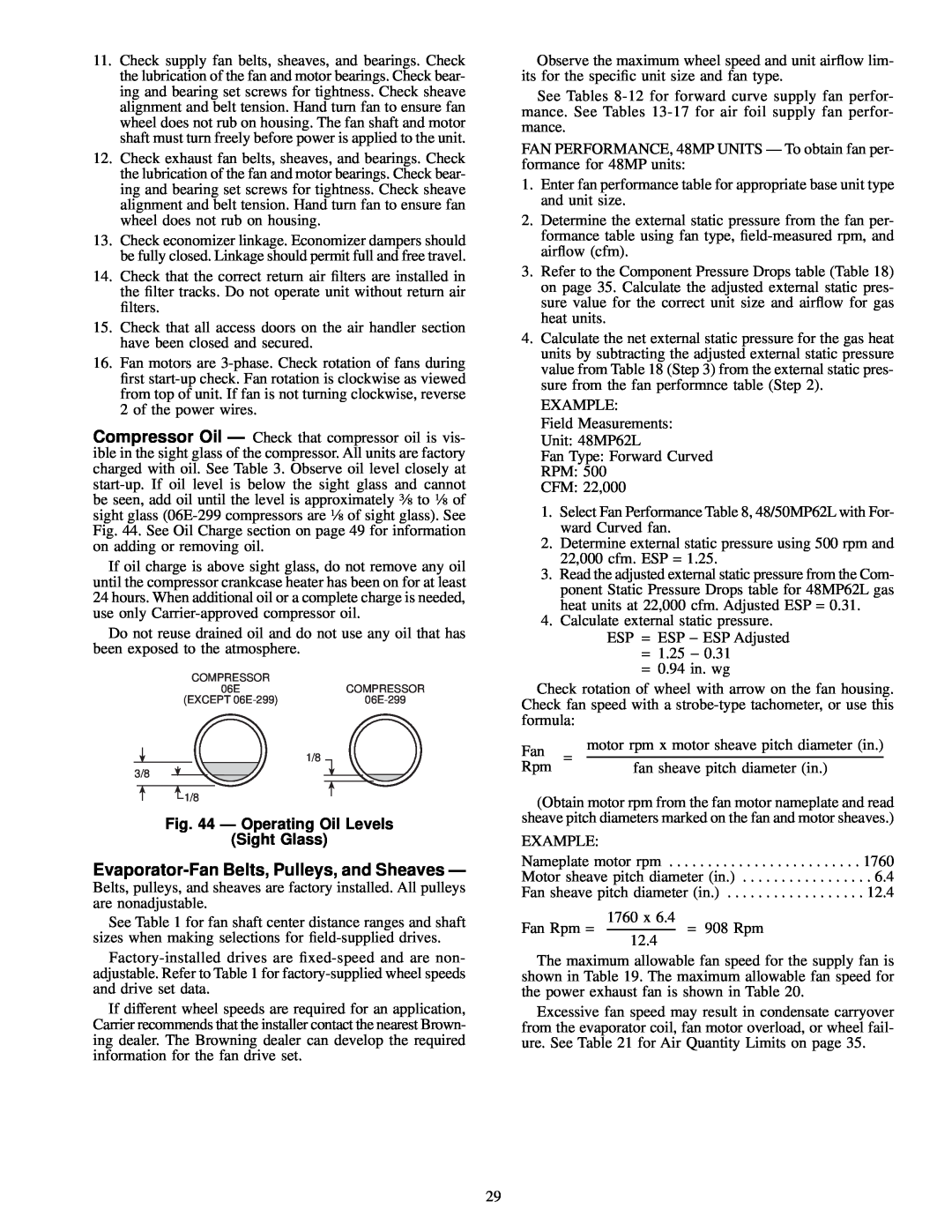

Compressor Oil Ð Check that compressor oil is vis- ible in the sight glass of the compressor. All units are factory charged with oil. See Table 3. Observe oil level closely at

If oil charge is above sight glass, do not remove any oil until the compressor crankcase heater has been on for at least 24 hours. When additional oil or a complete charge is needed, use only

Do not reuse drained oil and do not use any oil that has been exposed to the atmosphere.

COMPRESSOR |

|

06E | COMPRESSOR |

(EXCEPT |

1/8

3/8

![]() 1/8

1/8

Fig. 44 Ð Operating Oil Levels

(Sight Glass)

Evaporator-Fan Belts, Pulleys, and Sheaves Ð

Belts, pulleys, and sheaves are factory installed. All pulleys are nonadjustable.

See Table 1 for fan shaft center distance ranges and shaft sizes when making selections for

If different wheel speeds are required for an application, Carrier recommends that the installer contact the nearest Brown- ing dealer. The Browning dealer can develop the required information for the fan drive set.

Observe the maximum wheel speed and unit air¯ow lim- its for the speci®c unit size and fan type.

See Tables

FAN PERFORMANCE, 48MP UNITS Ð To obtain fan per- formance for 48MP units:

1.Enter fan performance table for appropriate base unit type and unit size.

2.Determine the external static pressure from the fan per- formance table using fan type,

3.Refer to the Component Pressure Drops table (Table 18) on page 35. Calculate the adjusted external static pres- sure value for the correct unit size and air¯ow for gas heat units.

4.Calculate the net external static pressure for the gas heat units by subtracting the adjusted external static pressure value from Table 18 (Step 3) from the external static pres- sure from the fan performnce table (Step 2).

EXAMPLE:

Field Measurements: Unit: 48MP62L

Fan Type: Forward Curved

RPM: 500

CFM: 22,000

1.Select Fan Performance Table 8, 48/50MP62L with For- ward Curved fan.

2.Determine external static pressure using 500 rpm and 22,000 cfm. ESP = 1.25.

3.Read the adjusted external static pressure from the Com- ponent Static Pressure Drops table for 48MP62L gas heat units at 22,000 cfm. Adjusted ESP = 0.31.

4.Calculate external static pressure.

ESP = ESP − ESP Adjusted

=1.25 − 0.31

=0.94 in. wg

Check rotation of wheel with arrow on the fan housing. Check fan speed with a

Fan | = | motor rpm x motor sheave pitch diameter (in.) |

Rpm | fan sheave pitch diameter (in.) |

(Obtain motor rpm from the fan motor nameplate and read sheave pitch diameters marked on the fan and motor sheaves.)

EXAMPLE:

Nameplate motor rpm . . . . . . . . . . . . . . . . . . . . . . . . . 1760 Motor sheave pitch diameter (in.) . . . . . . . . . . . . . . . . . 6.4 Fan sheave pitch diameter (in.) . . . . . . . . . . . . . . . . . . 12.4

| 1760 x 6.4 | ||

Fan Rpm = |

| = 908 Rpm | |

12.4 | |||

|

| ||

The maximum allowable fan speed for the supply fan is shown in Table 19. The maximum allowable fan speed for the power exhaust fan is shown in Table 20.

Excessive fan speed may result in condensate carryover from the evaporator coil, fan motor overload, or wheel fail- ure. See Table 21 for Air Quantity Limits on page 35.

29