3.6Print Head Offset Adjustments

CAUTION Ensure the print head offset adjustments are correct for your type of print media (thickness & width). Incorrect adjustments can cause premature failure of the print head.

The printer has already been

mm(4.4 in). However, the print head offset adjustments might be necessary depending on the width of the paper and the paper quality. If the print quality becomes inferior because of the use of the paper other than the standard, adjust it according to the following:

1.When the print is unclear or blurred because of poor paper quality:

Adjust the offset of the print head and platen by turning the offset adjust- screw. The print head offset adjustments are made by changing the inclination of the print head to the platen. This has already been

In those cases, make adjustments according to the criteria below.

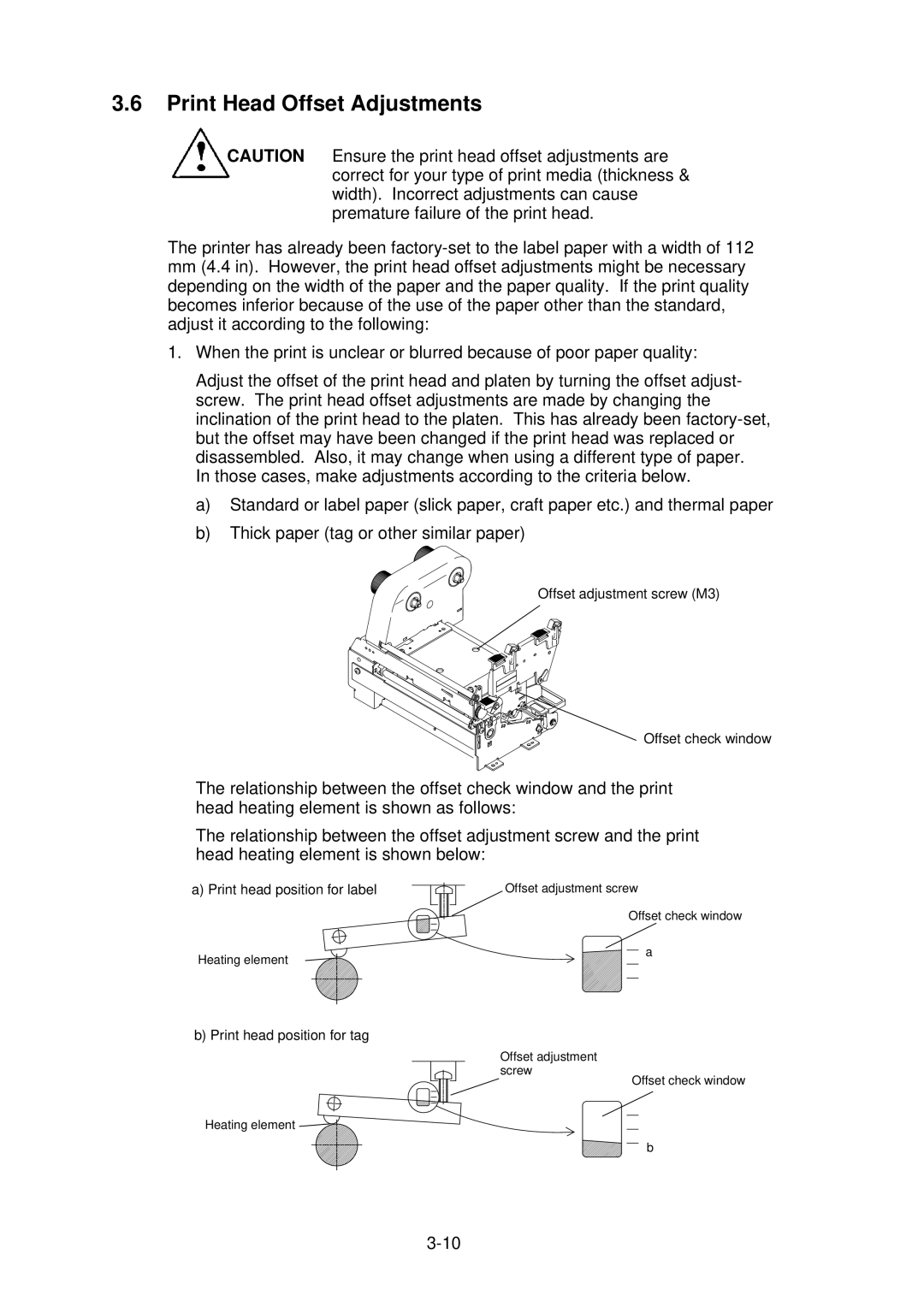

a)Standard or label paper (slick paper, craft paper etc.) and thermal paper

b)Thick paper (tag or other similar paper)

Offset adjustment screw (M3)

Offset check window

The relationship between the offset check window and the print head heating element is shown as follows:

The relationship between the offset adjustment screw and the print head heating element is shown below:

a) Print head position for label | Offset adjustment screw |

Offset check window

Heating element | a |

|

b) Print head position for tag

Offset adjustment screw

Heating element

Offset check window

b