MAINTENANCE

INSPECTION AND MAINTENANCE CHECKLIST

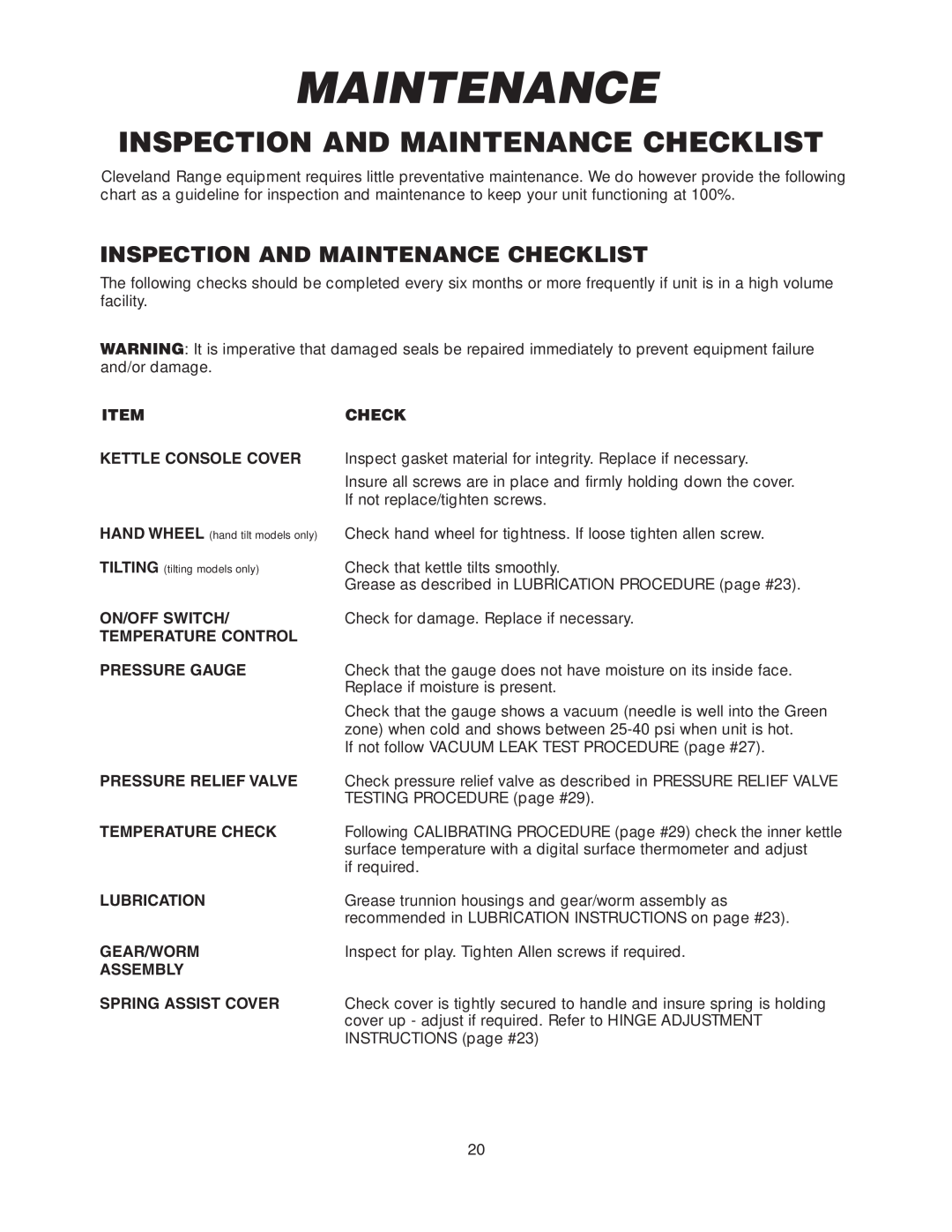

Cleveland Range equipment requires little preventative maintenance. We do however provide the following chart as a guideline for inspection and maintenance to keep your unit functioning at 100%.

INSPECTION AND MAINTENANCE CHECKLIST

The following checks should be completed every six months or more frequently if unit is in a high volume facility.

WARNING: It is imperative that damaged seals be repaired immediately to prevent equipment failure and/or damage.

ITEM | CHECK |

KETTLE CONSOLE COVER | Inspect gasket material for integrity. Replace if necessary. |

| Insure all screws are in place and firmly holding down the cover. |

| If not replace/tighten screws. |

HAND WHEEL (hand tilt models only) | Check hand wheel for tightness. If loose tighten allen screw. |

TILTING (tilting models only) | Check that kettle tilts smoothly. |

| Grease as described in LUBRICATION PROCEDURE (page #23). |

ON/OFF SWITCH/ | Check for damage. Replace if necessary. |

TEMPERATURE CONTROL |

|

PRESSURE GAUGE | Check that the gauge does not have moisture on its inside face. |

| Replace if moisture is present. |

| Check that the gauge shows a vacuum (needle is well into the Green |

| zone) when cold and shows between |

| If not follow VACUUM LEAK TEST PROCEDURE (page #27). |

PRESSURE RELIEF VALVE | Check pressure relief valve as described in PRESSURE RELIEF VALVE |

| TESTING PROCEDURE (page #29). |

TEMPERATURE CHECK | Following CALIBRATING PROCEDURE (page #29) check the inner kettle |

| surface temperature with a digital surface thermometer and adjust |

| if required. |

LUBRICATION | Grease trunnion housings and gear/worm assembly as |

| recommended in LUBRICATION INSTRUCTIONS on page #23). |

GEAR/WORM | Inspect for play. Tighten Allen screws if required. |

ASSEMBLY |

|

SPRING ASSIST COVER | Check cover is tightly secured to handle and insure spring is holding |

| cover up - adjust if required. Refer to HINGE ADJUSTMENT |

| INSTRUCTIONS (page #23) |

20