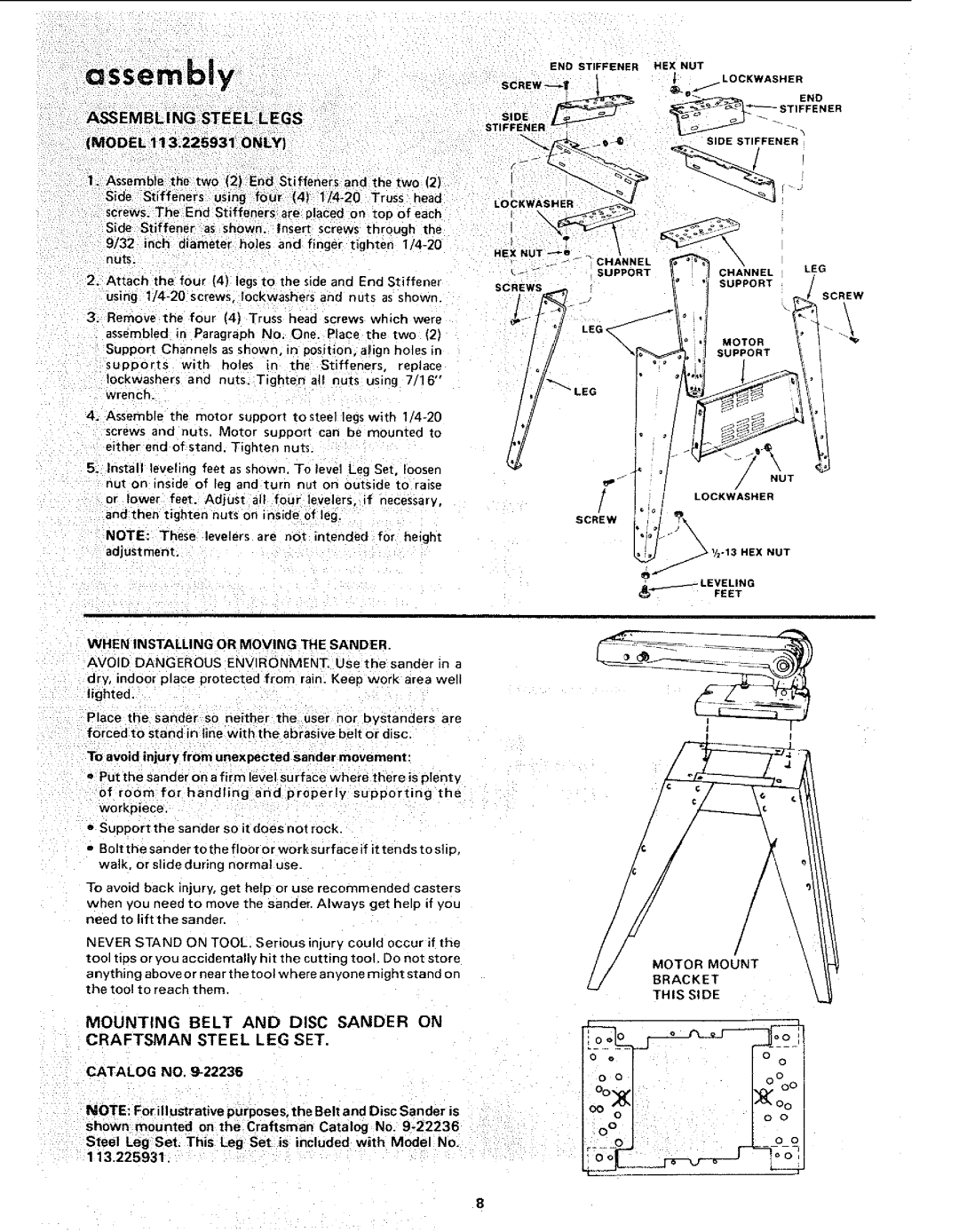

1. Assemble the two (2) End Stiffeners and the two 2 | ||||||

Side | Stiffeners | using four | (4) | Truss | head | |

screws. The End Stiffeners are placed On top of each | ||||||

Side | Stiffener | as shown. | Insert | screws | through | the |

END STIFFENER

SCREW _ 1

STIFFENERS,DE

LOCKWASHER

HEX NUT

LOCKWASHER

ST,FFEN R

SIDE STIFFENER

| 9/32 inch diameter holes and finger tighten | ||||||||||||||

| nutS. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2. | Attach |

| the | four | (4) | legs to the side and End | Stiffener |

| |||||||

| using | and | nuts | as shown. | |||||||||||

3. | Remove |

| the |

| four | (41 Truss | head | screws | which | were | |||||

| assembled in Paragraph No. One. Place the two (2 | ||||||||||||||

| Support |

| Channels | as shown, | in position |

| align holes | in | |||||||

| supports |

|

| with | holes | in | the | Stiffeners, |

| replace | |||||

| Iockwashers |

| and nuts, Tighten all nuts using 7/16 |

| |||||||||||

| wrench. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. | Assemble | the | motor | support | to steel | legs with | |||||||||

| screws | and | nuts. | Motor | support | can | be | mounted | to | ||||||

| either end of stand. Tignlen nuts |

|

|

|

|

|

| ||||||||

5. | Install | leveling | feet | as shown. | To | level | Leg Set, | loosen | |||||||

|

| \ | |

HEX NUT | _e | _ CH/%NNEL | |

| .r | ||

_- _ | SUPPORT | ||

|

_ | k | _. |

LEG

\

CHANNEL SUPPORT

MOTOR SUPPORT

LEG

SCREW

nut | on | inside of | leg | and | turn | nut | on outside to raise |

or lower feet. Adjust alt four levelers, if necessary, | |||||||

and | then | tighten | nuts | on | inside | of | leg. |

NOTE: These levelers are not intended for height adjustment.

WHEN INSTALLING OR MOVING THE SANDER.

AVOID DANGEROUS ENVIRONMENT, Use the sander n a dry, indoor place protected from rain. Keen work area well lighted.

Place the sander so neither the user nor bystanders are forced to stand in line with the abrasive belt or d sc.

To avoid injury from unexpected sandel movement:

=Put the sander on a firm level surface where there is plenty

of room for handling and properly supporting the workpiece.

- Support the sander so it does not rock.

,,Bolt the sander tothe floor or work surfaceif it tends to slip, walk. or slide during normal use.

To avoid back injury, get help or use recommended casters when you need to move the sander. Always get help if you need to lift the sander.

NEVER STAND ON TOOL. Serious injury could occur if the too] tips or you accidentally hit the cutting tool, Do not store

anything above or near the toot where anyone might stand on the tool to reach them.

/

SCREW

/NUT

LOCKWASHER

#

MOTOR MOUNT

BRACKET

THISSIDE

MOUNTING BELT AND DISC SANDER ON

CRAFTSMAN STEEL LEG SET.

CATALOG NO. 9-22236

NOTE: Forillustrative purposes, the Belt and Disc Sander is shown mounted on the Craftsman Catalog No.

0 C | OOc |

o°o

o o

___coc