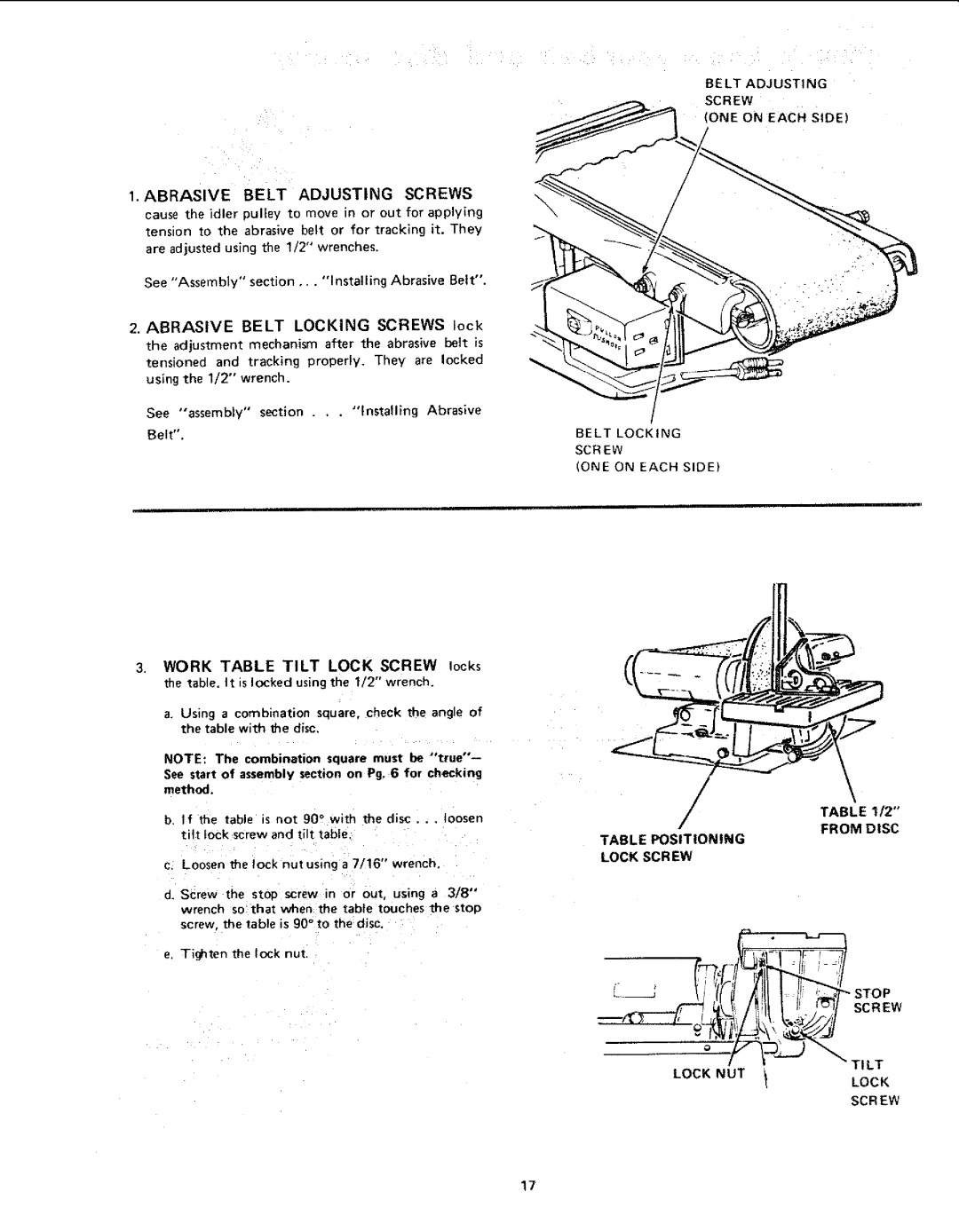

1. ABRASIVE BELT ADJUSTING SCREWS

cause the idler pulley to move in or out for applying tension to the abrasive belt or for tracking it. They are adjusted using the 1/2" wrenches,

See "Assembly" section... "Installing Abrasive Belt".

2. ABRASIVE BELT LOCKING SCREWS lock the adjustment mechanism after the abrasive belt is tensioned and tracking properly, They are locked using the 1/2" wrench.

See "assembly" section . . . "Installing Abrasive Belt".

3, WORK TABLE TILT LOCK SCREW locks

the table. It is locked using the 1/2" wrencn.

a. Using a combination square, check the angle of the table with the disc.

NOTE: The :ombination square must be

See start of assembly section on Pg. 6 for checking method.

b. If the table Js not 90 ° with the disc.., loosen tilt Ic_ck screw and ti t table,

c. Loosen the lock nut using a 7/16" wrench.

d. Screw the atop screw in or out. using a 3/8"" wrench so that when the table touches the stop screw, the table is 90 ° to the disc.

e. Tighten the lock nut

BELT ADJUSTING

SCREW

(ONE ON EACH SIDE)

BELT LOCKING

SCREW

(ONE ON EACH SIDE)

|

| \ |

| |

| / | TABLE | 1/2" | |

| FROM | DISC | ||

TABLE | POSITIONING | |||

|

| |||

LOCK | SCREW |

|

|

STOP

SCREW

_" TILT

LOCK NUT

LOCK

SCREW

17