Venting Installation

Instructions

Continued

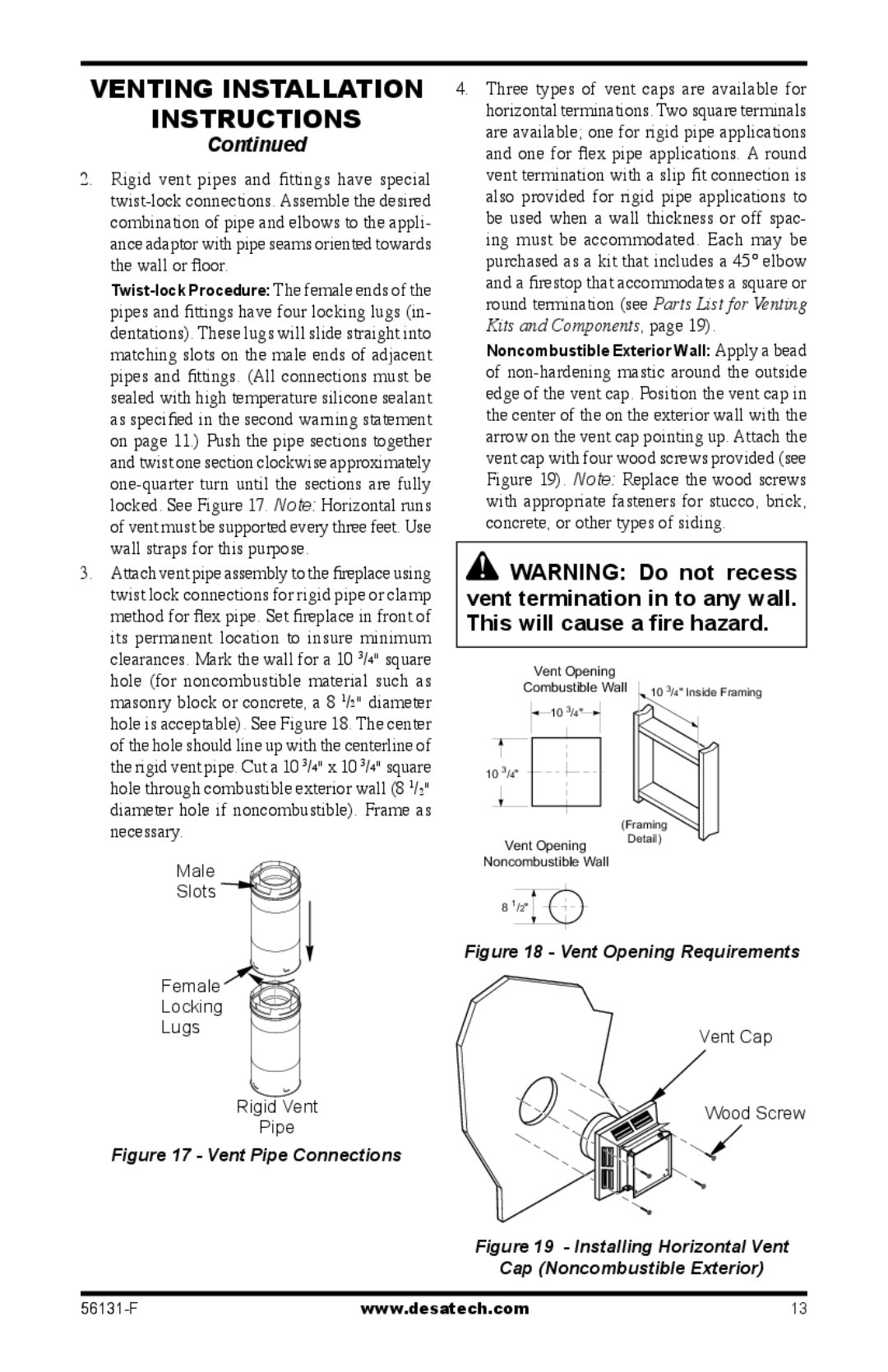

2. Rigid vent pipes and fittings have special | ||||

combination of pipe and elbows to the appli- | ||||

ance adaptor with pipe seams oriented towards | ||||

the wall or floor. |

|

|

|

|

pipes and fittings have four locking lugs (in- | ||||

dentations). These lugs will slide straight into | ||||

matching slots on the male ends of adjacent | ||||

pipes and fittings. (All connections must be | ||||

sealed with high temperature silicone sealant | ||||

as specified in the second warning statement | ||||

on page 11.) Push the pipe sections together | ||||

and twist one section clockwise approximately | ||||

locked. See Figure 17. Note: Horizontal runs | ||||

of vent must be supported every three feet. Use | ||||

wall straps for this purpose. |

|

|

|

|

3. Attach vent pipe assembly to the fireplace using | ||||

twist lock connections for rigid pipe or clamp | ||||

method for flex pipe. Set fireplace in front of | ||||

its permanent location to insure minimum | ||||

clearances. Mark the wall for a 10 3/4" square | ||||

hole (for noncombustible material such as | ||||

masonry block or concrete, a 8 | 1 | 2 |

| |

| / " diameter | |||

hole is acceptable). See Figure 18. The center | ||||

of the hole should line up with the centerline of | ||||

3 | 4 |

| 3 | 4 |

the rigid vent pipe. Cut a 10 / " x 10 / " square | ||||

hole through combustible exterior wall (8 1/2" | ||||

diameter hole if noncombustible). Frame as | ||||

necessary. |

|

|

|

|

4.Three types of vent caps are available for horizontal terminations. Two square terminals are available; one for rigid pipe applications and one for flex pipe applications. A round vent termination with a slip fit connection is also provided for rigid pipe applications to be used when a wall thickness or off spac- ing must be accommodated. Each may be purchased as a kit that includes a 45° elbow and a firestop that accommodates a square or round termination (see Parts List for Venting Kits and Components, page 19).

Noncombustible Exterior Wall: Apply a bead of

![]() WARNING: Do not recess vent termination in to any wall. This will cause a fire hazard.

WARNING: Do not recess vent termination in to any wall. This will cause a fire hazard.

Vent Opening

Combustible Wall | 10 3/4" Inside Framing |

10 3/4" |

|

103/4"

(Framing

Vent Opening

Detail)

Male

Slots

Female

Locking

Lugs

Rigid Vent

Pipe

Figure 17 - Vent Pipe Connections

Noncombustible Wall

8 1/2"

Figure 18 - Vent Opening Requirements

Vent Cap

Wood Screw

Figure 19 - Installing Horizontal Vent

Cap (Noncombustible Exterior)

www.desatech.com | 13 |