Rosemount 1154

Reference Manual

Conduit

1.Seal the conduit threads with thread sealant. (The transmitter conduit seal interface was qualified using Grafoil™ tape.) Conduit threads mate with a standard

2.Starting at zero thread engagement, install the conduit into the transmitter between 4 and 7 turns, or a minimum of 12.5

3.Provide separate support for the conduit if necessary.

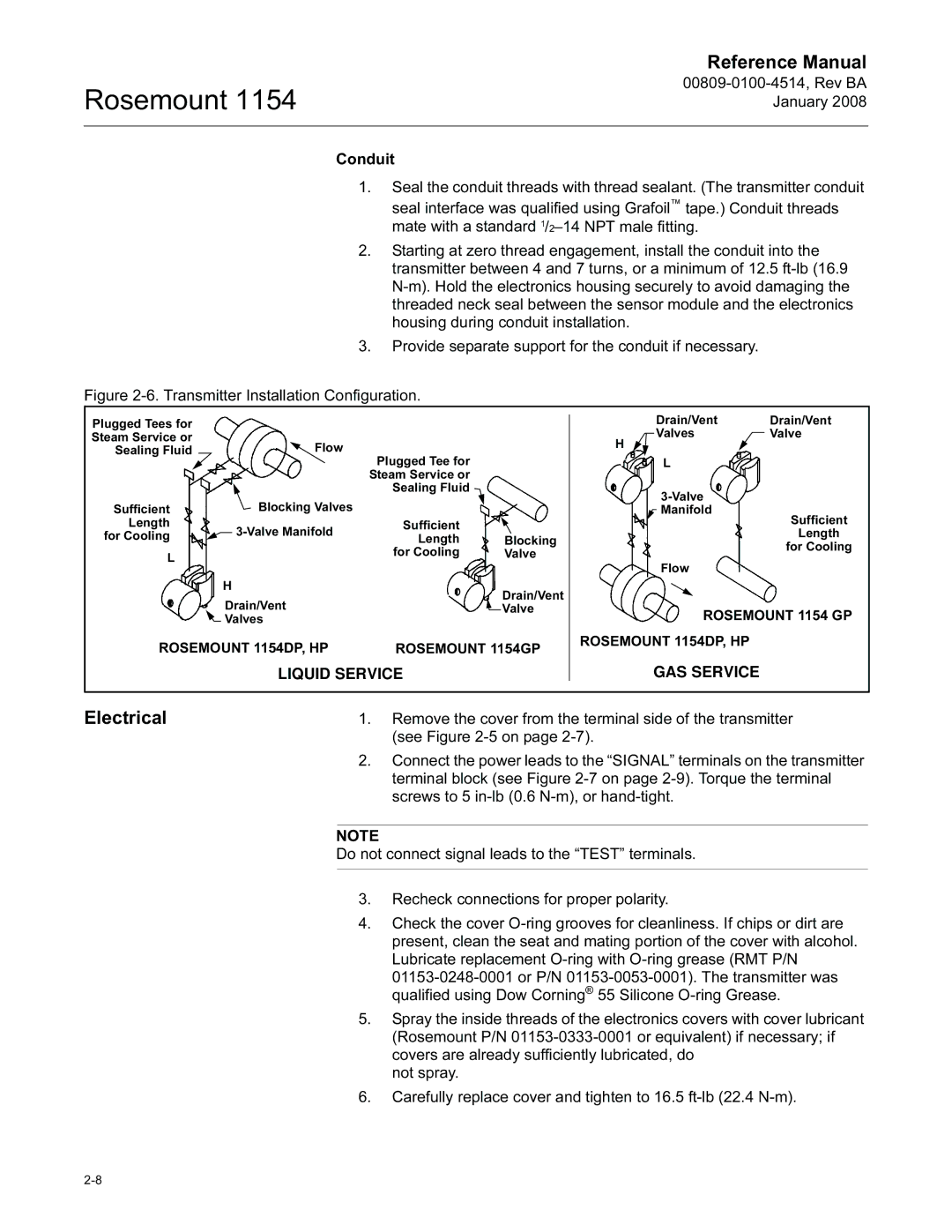

Figure 2-6. Transmitter Installation Configuration.

Plugged Tees for |

|

Steam Service or | Flow |

Sealing Fluid |

|

| Plugged Tee for |

| |

|

| Steam Service or |

| |

|

| Sealing Fluid |

| |

Sufficient | Blocking Valves |

|

| |

Length | Sufficient |

| ||

for Cooling |

| |||

Length | Blocking | |||

| ||||

|

| |||

L |

| for Cooling | Valve | |

|

|

| ||

| H |

| Drain/Vent | |

| Drain/Vent |

| ||

|

| Valve | ||

| Valves |

| ||

|

|

| ||

ROSEMOUNT 1154DP, HP | ROSEMOUNT 1154GP | |||

LIQUID SERVICE

Drain/Vent | Drain/Vent |

Valves | Valve |

H |

|

L |

|

![]()

![]() Manifold

Manifold

Sufficient

Length

for Cooling

Flow

ROSEMOUNT 1154 GP

ROSEMOUNT 1154DP, HP

GAS SERVICE

Electrical | 1. | Remove the cover from the terminal side of the transmitter | |

|

|

| (see Figure |

| 2. | Connect the power leads to the “SIGNAL” terminals on the transmitter | |

|

|

| terminal block (see Figure |

|

|

| screws to 5 |

|

|

|

|

| NOTE |

| |

| Do not connect signal leads to the “TEST” terminals. | ||

|

|

|

|

| 3. | Recheck connections for proper polarity. | |

| 4. | Check the cover | |

|

|

| present, clean the seat and mating portion of the cover with alcohol. |

|

|

| Lubricate replacement |

|

|

| |

|

|

| qualified using Dow Corning® 55 Silicone |

| 5. | Spray the inside threads of the electronics covers with cover lubricant | |

|

|

| (Rosemount P/N |

|

|

| covers are already sufficiently lubricated, do |

|

|

| not spray. |

| 6. | Carefully replace cover and tighten to 16.5 | |