ADJUSTING THE BALL BEARINGS AGAINST THE TRACK

![]() To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and removing accessories, before adjusting or changing

To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and removing accessories, before adjusting or changing

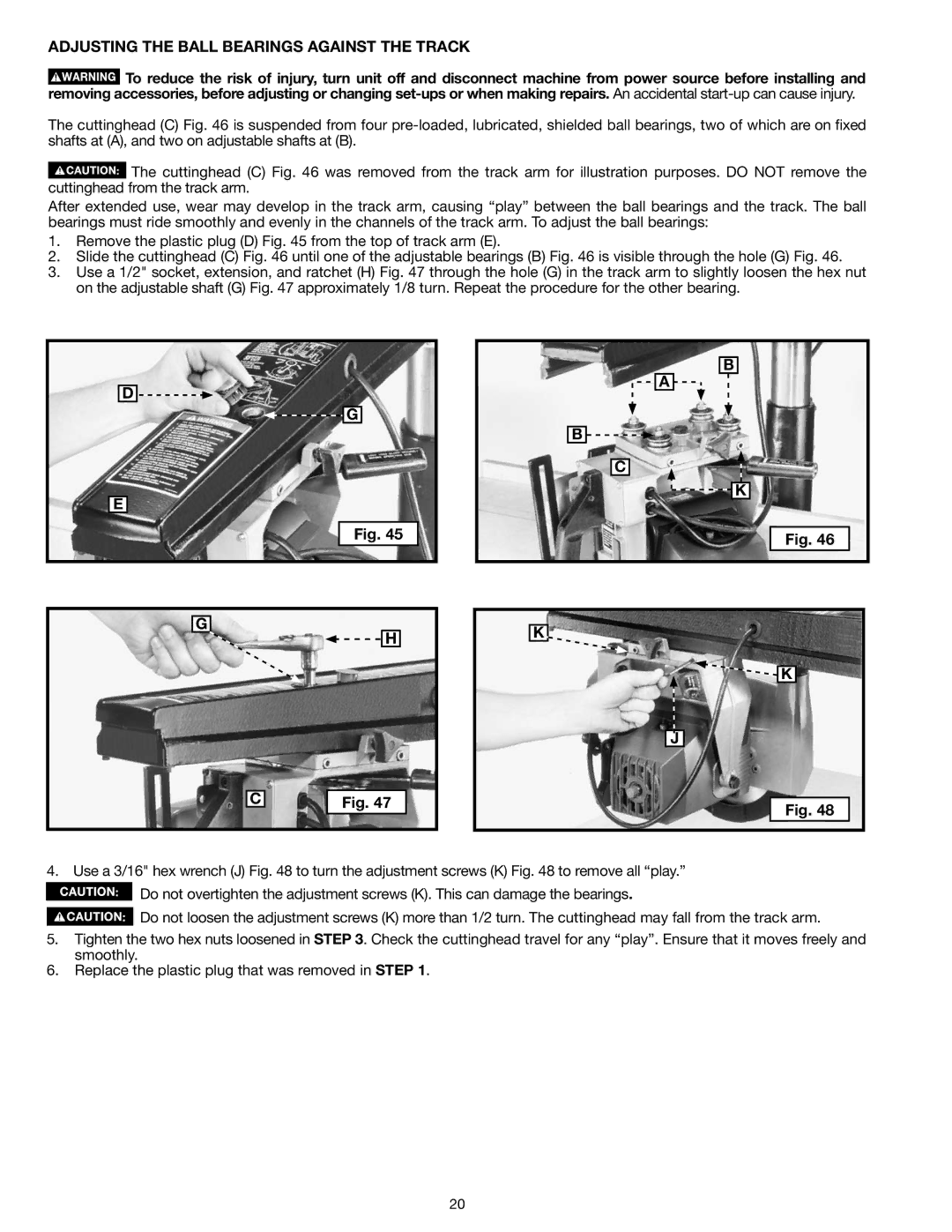

The cuttinghead (C) Fig. 46 is suspended from four

![]() The cuttinghead (C) Fig. 46 was removed from the track arm for illustration purposes. DO NOT remove the cuttinghead from the track arm.

The cuttinghead (C) Fig. 46 was removed from the track arm for illustration purposes. DO NOT remove the cuttinghead from the track arm.

After extended use, wear may develop in the track arm, causing “play” between the ball bearings and the track. The ball bearings must ride smoothly and evenly in the channels of the track arm. To adjust the ball bearings:

1.Remove the plastic plug (D) Fig. 45 from the top of track arm (E).

2.Slide the cuttinghead (C) Fig. 46 until one of the adjustable bearings (B) Fig. 46 is visible through the hole (G) Fig. 46.

3.Use a 1/2" socket, extension, and ratchet (H) Fig. 47 through the hole (G) in the track arm to slightly loosen the hex nut on the adjustable shaft (G) Fig. 47 approximately 1/8 turn. Repeat the procedure for the other bearing.

D ![]()

![]()

![]()

![]() G

G

B

![]() A

A ![]()

B

C

E

G

Fig. 45

![]()

![]() H

H

![]()

![]() K

K

Fig. 46

K

![]()

![]() K

K

J

|

|

|

C | Fig. 47 | |

|

Fig. 48

4.Use a 3/16" hex wrench (J) Fig. 48 to turn the adjustment screws (K) Fig. 48 to remove all “play.” ![]() Do not overtighten the adjustment screws (K). This can damage the bearings.

Do not overtighten the adjustment screws (K). This can damage the bearings.

![]() Do not loosen the adjustment screws (K) more than 1/2 turn. The cuttinghead may fall from the track arm.

Do not loosen the adjustment screws (K) more than 1/2 turn. The cuttinghead may fall from the track arm.

5.Tighten the two hex nuts loosened in STEP 3. Check the cuttinghead travel for any “play”. Ensure that it moves freely and smoothly.

6.Replace the plastic plug that was removed in STEP 1.

20