8196345 specifications

The Frymaster 8196345 is a premier commercial fryer designed to meet the demanding needs of foodservice operations. Renowned for its efficiency and technology, this versatile model is a popular choice among restaurants, food trucks, and catering companies.One of the standout features of the Frymaster 8196345 is its high-capacity oil filtration system. This system ensures that the oil remains clean and free of food particles, significantly extending the life of the oil and enhancing the flavor of fried foods. With automatic filtration capabilities, operators can focus on food preparation rather than oil maintenance, resulting in higher efficiency in busy kitchen environments.

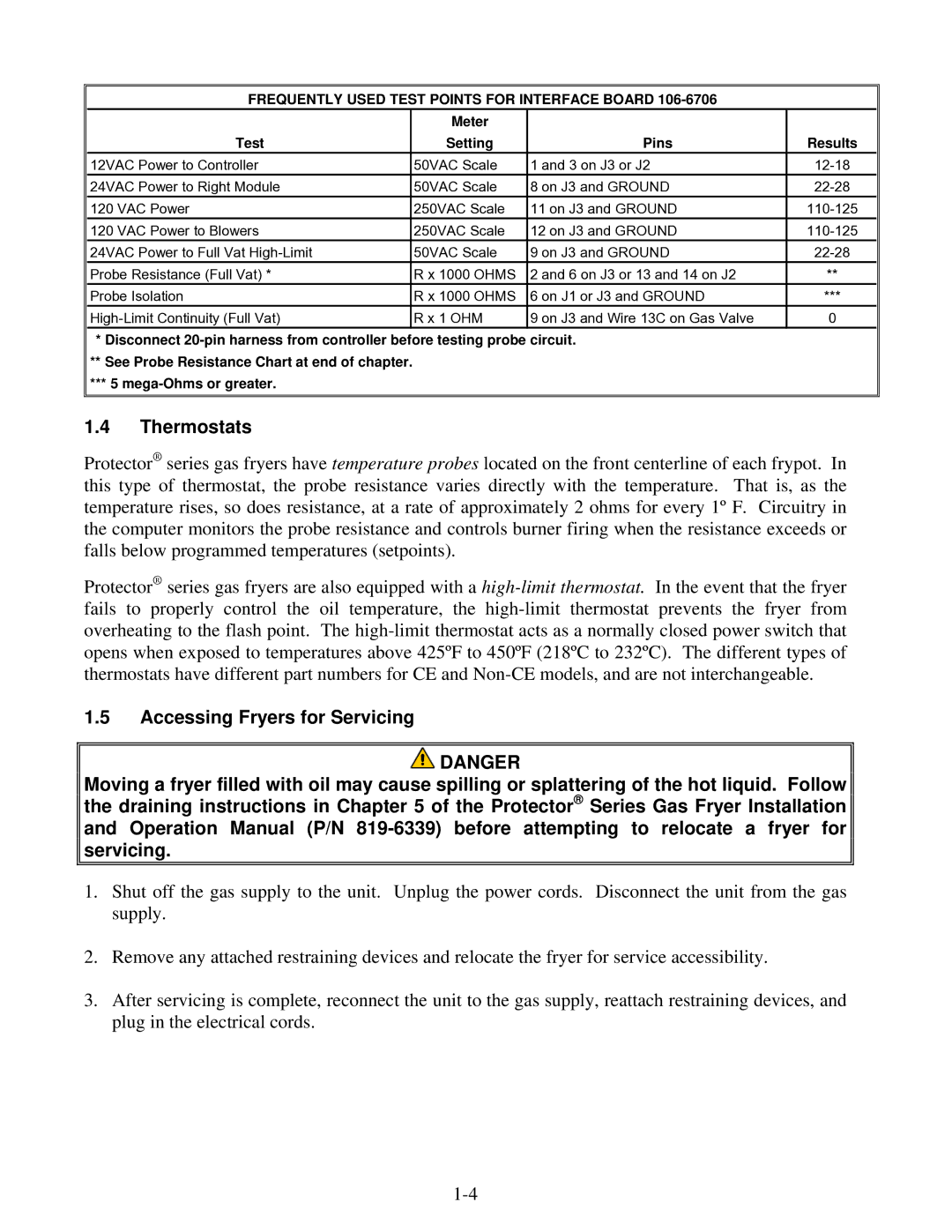

The Frymaster 8196345 also incorporates advanced temperature control technology. With precise digital thermostats, the fryer maintains consistent oil temperatures, reducing the risk of overcooking or burning food. This feature is crucial for achieving optimal frying results, especially for delicate items like fish or pastries. The user-friendly controls allow for quick adjustments, ensuring that chefs can adapt to various cooking requirements seamlessly.

Another key characteristic of the Frymaster 8196345 is its durable construction. Built with high-quality stainless steel, this fryer is designed to withstand the rigors of daily use, providing operators with a long-lasting investment. The smooth surfaces also make cleaning and maintenance significantly easier, helping to meet health and safety standards in commercial kitchens.

The Frymaster 8196345 can accommodate multiple basket sizes, allowing users to fry different foods simultaneously without compromising on quality. This flexibility is particularly beneficial during peak service times, allowing establishments to maximize output and minimize wait times for customers.

Additionally, the Frymaster 8196345 is designed with energy efficiency in mind. It features an eco-friendly operation mode, which reduces energy consumption without sacrificing performance. This not only lowers operational costs but also aligns with sustainability initiatives that many modern establishments strive for.

In summary, the Frymaster 8196345 is an exceptional commercial fryer that combines advanced technology, durability, and efficiency. Its high-capacity oil filtration system, precise temperature control, and robust build make it an ideal choice for busy kitchens aiming for consistent, high-quality frying results. Whether it’s for crispy fries, tempura, or chicken wings, the Frymaster 8196345 stands out as a reliable partner for any food service operation.