8196004

24-Hour Service Hotline

andPartsManualService,Operation,Installation

FRYERS

DANGER

CANADA

Never spray the fryer with water or use water jets to clean the fryer

NOTICE TO U.S. CUSTOMERS

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS U.S

Navy Surface Ship Electric Fryers

Installation, Operation, Service, and Parts Manual TABLE OF CONTENTS

1.1 General

1.2 Safety Information

NAVY SURFACE SHIP ELECTRIC FRYERS CHAPTER 1 INTRODUCTION

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE

1.4 Shipping Damage Claim Procedure

1.5 Service Information

1.3 Controller Information

Do not block the area around the base or under the fryers

NAVY SURFACE SHIP ELECTRIC FRYERS CHAPTER 2 INSTALLATION INSTRUCTIONS

2.1 Introduction

The contacts CANNOT have an external voltage applied

2.2 Power Requirements

Do not connect the contacts in series

Do not connect more than one fryer to each set of contacts

2.4 After Fryers Are Anchored At the Frying Station DANGER

2.3 Installation

2.5 Dimensions and Weights

BACK OF FRYER UNIT

2-Fryer Battery

Single Fryer

FRONT HANDLE

62.55

3-Fryer Battery

4-Fryer Battery

2.470

NAVY SURFACE SHIP ELECTRIC FRYERS CHAPTER 3 OPERATING INSTRUCTIONS

3.1 Equipment Setup and Shutdown Procedures

DESCRIPTION

3.2 Operation of the Solid-State Analog Controller

Shutdown

The analog controller has no timing features. The operator must monitor shake and pull times

properly filled with oil. See Section CONTROLLER OPERATING PROCEDURE

HIGH-LIMIT TEST PROCEDURE

5. Place the controller power switch in the OFF position

4.2 Preparing the Filter for Use

NAVY SURFACE SHIP ELECTRIC FRYERS CHAPTER 4 FILTRATION INSTRUCTIONS

4.1 Introduction

3. Place the metal filter screen in the center of the bottom of the pan, then lay a sheet of filter paper on top of the screen, over- lapping on all sides

4.3 Operation of the Filter DANGER

2. Remove the basket support rack from the frypot, raise the element assembly to the up position, and snap the Power Shower into position

6. Lower the elements into the frypot and reinstall the basket support rack. Ensure the drain valve is fully closed. If the drain valve is not fully closed, the fryer will not operate. Turn the fryer ON and allow the cooking oil to reach setpoint

4.4 Draining and Disposing of Waste Oil

5.1.2 Clean the Built-in Filtration System - Daily

NAVY SURFACE SHIP ELECTRIC FRYERS CHAPTER 5 PREVENTIVE MAINTENANCE

5.1 Cleaning the Fryer DANGER

5.1.1 Clean Inside and Outside of the Fryer Cabinet - Daily

2. Press the fryer ON/OFF switch to the ON position

5.1.3 Clean the Frypot and Heating Elements - Weekly DANGER

Boiling-Out the Frypot

5. Turn the fryer ON/OFF switchs to the OFF position

5.1.4 Clean Detachable Parts and Accessories - Weekly

5.2 Check Calibration of Temperature Control Knob - Monthly

Built-In Filtration System

5.3 Annual/Periodic System Inspection

Fryer

Check filtration system integrity as follows

− Verify that filter pan cover is present and properly installed

Verify that frypot drain valves are fully closed

NAVY SURFACE SHIP ELECTRIC FRYERS CHAPTER 6 OPERATOR TROUBLESHOOTING

6.1 Introduction

Verify that power is connected and that circuit breakers are on

Corrective Action

Problem

6.2 Troubleshooting 6.2.1 Control and Heating Problems

Probable Causes

Probable Causes

6.2.3 Filtration Problems

6.2.2 Error Messages and Display Problems

Filter pump runs

6.3 Replacing the Controller or Controller Wiring Harness

7.2 Replacing a Controller

NAVY SURFACE SHIP ELECTRIC FRYERS CHAPTER 7 SERVICE PROCEDURES

7.1 General

7.3 Replacing Component Box Components

1. Remove the filter pan and lid from the unit. Drain the frypots into a Shortening Disposal Unit SDU or other appropriate container

7.4 Replacing a Temperature Probe or High-Limit Thermostat

DO NOT drain more than one full frypot into the SDU at one time

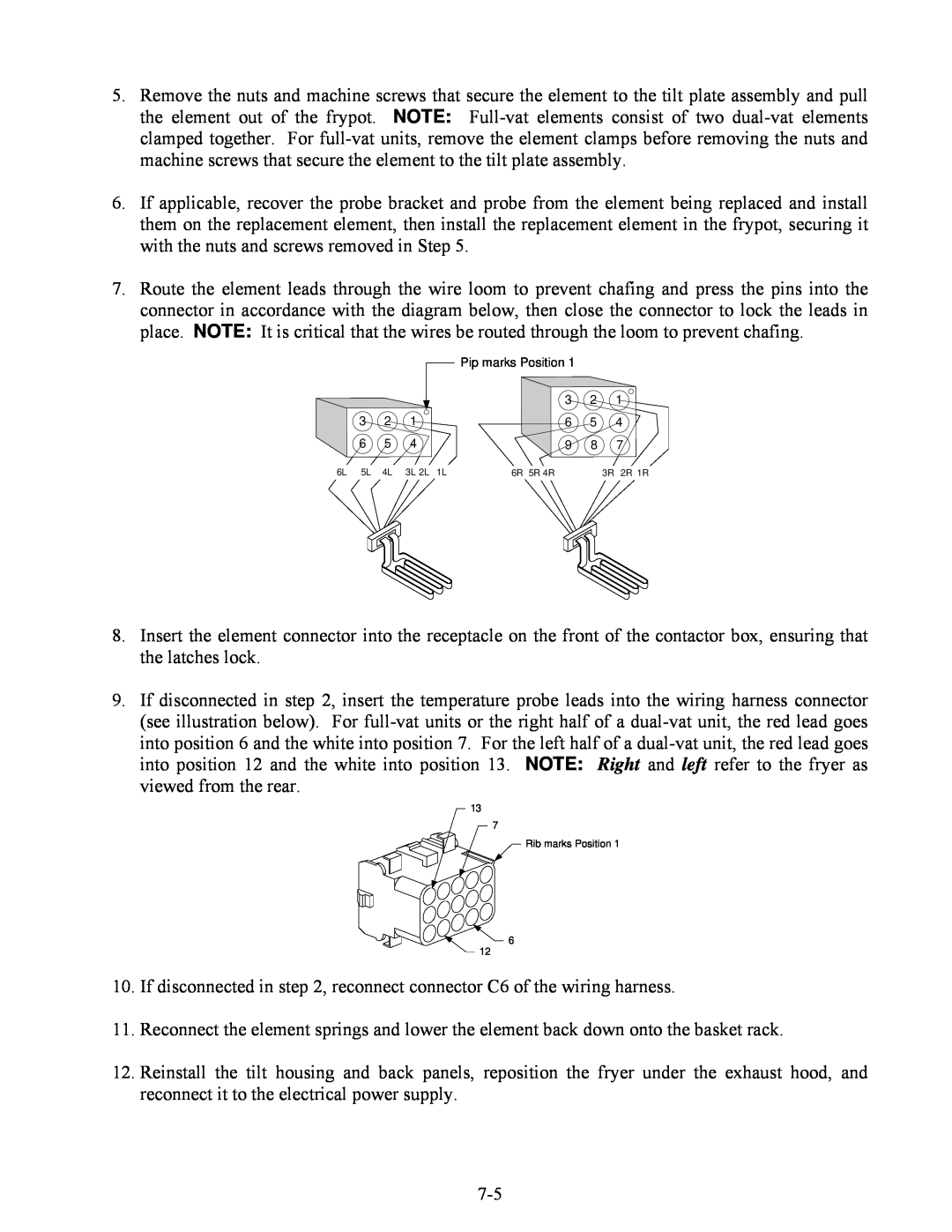

7.5 Replacing a Heating Element

viewed from the rear

7.7 Replacing a Frypot

7.6 Replacing Contactor Box Components

12. Disconnect the oil return flexlines at the frypot ends

22. Reinstall the drain tube assembly

Sediment Particle Oil Flow Up for reverse Down for forward

7.8.2 Replacing the Filter Motor, Filter Pump, and Related Components

7-10

7.8.3 Replacing the Filter Transformer or Filter Relay

Test

7.9 Interface Board Diagnostic Chart

Diagnostic LED Legend

Meter Setting

8051421F

7.10 Wiring Diagram, System

Refer to page 2-2 for power requirements

7-13

7-14

7.11 Wiring Diagram, Contactor Box

7.12 Components Description of Operation

Accessories

NAVY SURFACE SHIP ELECTRIC FRYERS CHAPTER 8 PARTS LIST

8.2 Cabinetry

106-3036SP

Side, Cabinet Single Left Use 212-8479 for Rt. Side

Handle Grab Rail For handle end use

Top Cap Single Top cap for five station fryer shown

8.2.2 Cabinet Bases, Braces, and Associated Parts

8.2.2 Cabinet Bases, Braces, and Associated Parts cont

Upright Assembly, Left Use 106-3828 for singles

Upright Assembly, Right Use 106-3829 for singles

Channel, Base Rear Use 106-4901 for singles base assembly

8.3.1 Drain Tube Sections and Associated Parts

8.3 Drain System Components

Valve Detail

8.3.1.1 Euro-Look Drain Tube Section and Associated Parts

See Page 8-10 for Drain

EURO-LOOK

8.3.1.1 Euro-Look Drain Tube Section and Associated Parts cont

8.3.2 Drain Valve Assembly and Component Parts

Page

ITEM EURO-LOOK

8.4 Electronics and Wiring Components 8.4.1.1 Single Component Box

8.4.1.2 Multiple Vat Component Boxes

8.4.2.1 Single Contactor Box

8.4.2.2 Multiple Vat Contactor Boxes

8.4.3 Heating Element Assembly and Associated Parts

8.4.3 Heating Element Assembly and Associated Parts cont

8.4.4

Wiring

8.4.5.1 Contactor Box Wiring Assembly - 12-Pin Full-Vat C-1

8.4.5.2 Contactor Box Wiring Assemblies - 6-Pin Left Element

P/N 106-3467SP 14/17kW or P/N 106-2472SP 22kW

8.4.5.3 Contactor Box Wiring Assemblies - 9-Pin Right Element

8.4.5.4 Single Contactor Box Wiring Assembly

8.4.5.5 Main Wiring Harness

8.4.5.9 Single Component Box Wiring Harness - 15-Pin without Filter

8.4.5.6 Single Main Wiring Harness

8.4.5.7 Component Box Wiring Harness - 15-Pin

8.4.5.8 Single Component Box Wiring Harness - 15-Pin

8.5.1 FPH117/122 Filtration Components

8.5 Filtration System Components

8.5.1 FPH117/122 Filtration Components cont

NOTE Some early production

8.5.2 FPH217/317 Multiple Battery Filtration System Components

units were configured this way

Lid for units built before Feb 04, use

8.5.2 FPH217/317 Multiple Battery Filtration System Components cont

STANDARD

EURO-LOOK

Thermostat P/N

8.6 Frypot Assembly and Thermostat

Frypot P/N 823-2451SP

8.7 Oil Return System Components

8.7 Oil Return System Components cont

COMPONENT

8.8 WIRING CONNECTORS, PIN TERMINALS, AND POWER CORDS

Power Cords

Connectors

Tech Support

SERVICE HOTLINE

Shipping Address 8700 Line Avenue, Shreveport, Louisiana

FAX Parts

![]() 6 12

6 12