Consumer Support . . . . . . . Back Cover

Write the model and serial numbers here Model # Serial #

California Safe Drinking Water and Toxic Enforcement Act

For complete details, follow the Installation Instructions

Clear the room, building or area of all occupants

Exhaust/Ducting

Ge.com

Never climb on or stand on the dryer top

When not Using Your Dryer

Quick Start

Power

About the dryer control panel

Cycle Knob

Sensor Dry Level

Dry Cycles

Timed Dry

Dry Temp

Clean Lint Filter message

To store a MY Cycle combination of settings

Display

Specialty Cycles include Garments

Specialty Cycles

Washer Communicated Cycles

Bed and Bath

About cycle options

Drum Lamp

About dryer features

Settings

Built-In Rack Dry System

Reverse Tumble

To Use the Built-In Hook for Hanging Garments

Sorting and Loading Hints

Using the dryer

Care and Cleaning of the Dryer

Fabric Care Labels

Before YOU Begin

For Your Safety

DPVH890 and UPVH890

For GAS Models only

Minimum Clearance Other than Alcove or Closet Installation

Installation Instructions

Dryer Dimensions

Location of Your Dryer

Installation must conform to

Bathroom or Bedroom Installation

Mobile or Manufactured Home Installation

Dryer Must be vented to the outdoors. See

Water Supply Requirements

Connecting Inlet Hoses

Connecting Inlet Hoses

By hand until firmly seated

Tools YOU will Need

Materials YOU will Need

Dryer GAS Supply Connection

Installation Instructions Connecting a GAS Dryer

GAS Requirements

GAS Supply

Attach the flexible metal gas line connector to the adapter

Connecting the Dryer To the GAS Supply

Connecting the Dryer

To prevent twisting the inlet

Electrical Connection Information for GAS Dryers

Test for Leaks

Electrical Requirements For GAS Dryers

Ensure proper ground exists before use

Materials YOU will Need For Your Safety

Electrical Connection Information for Electric Dryers

Grounding Instructions

Installation Instructions Connecting AN Electric Dryer

Electrical Requirements For Electric Dryers

Connecting Dryer Using 3-WIRE Connection

Exhausting the Dryer

Exhaust System Checklist

Tools and Materials YOU will Need to Install Exhaust Duct

For Transition Venting Dryer to WALL, do

Using Flexible Metal Duct for Transition Venting

Do not

Do not set dryer on duct

Responsibility

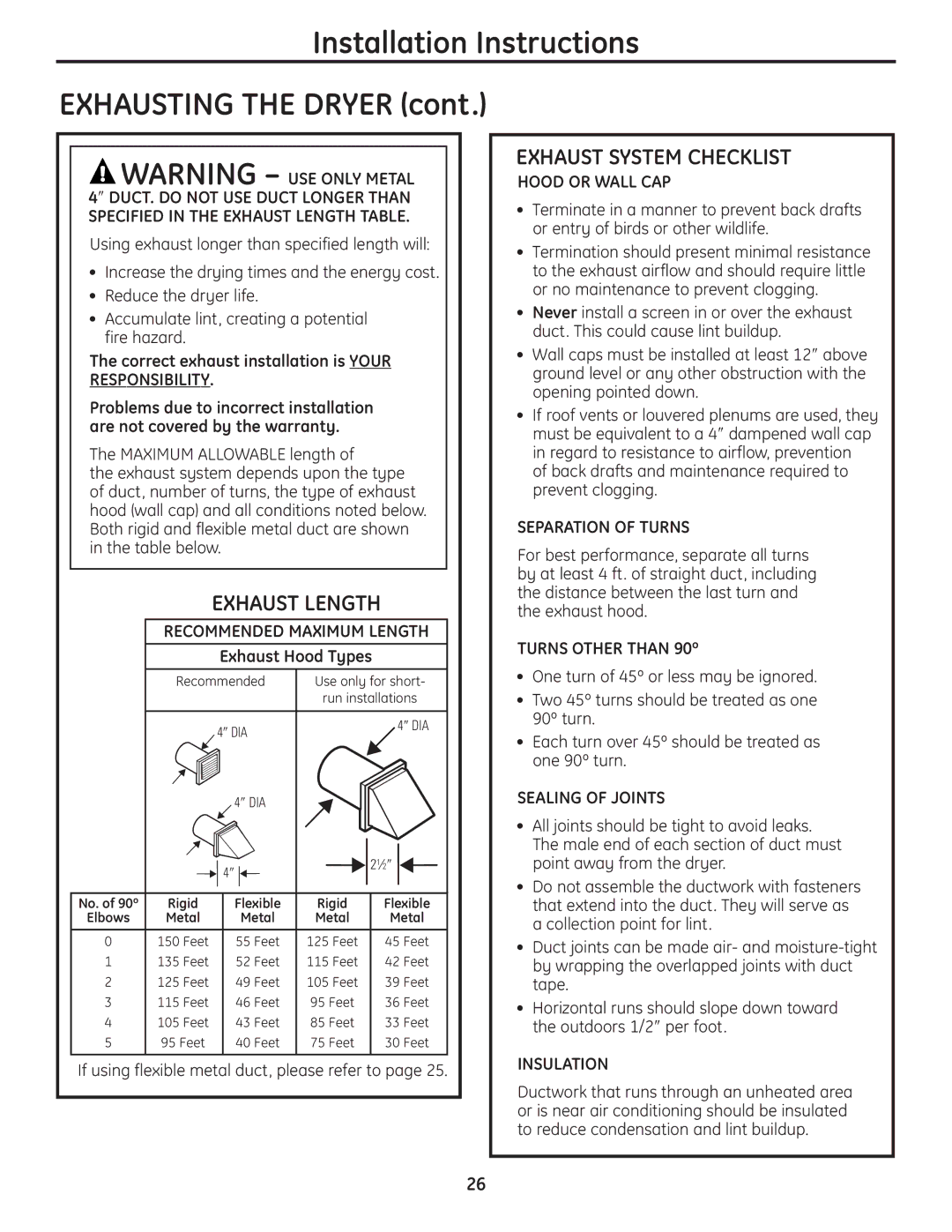

Exhaust Length

Specified in the Exhaust Length Table

Recommended Maximum Length

Standard Rear Exhaust

Recommended Configuration to Minimize Exhaust Blockage

Using duct elbows will prevent duct kinking and collapsing

Remove any lint from the wall exhaust opening

TAB Location

Installation Instructions Exhausting the Dryer

Side Venting

Adding a NEW Duct

Bottom Venting

Adding Cover Plate to Rear of Cabinet Side Exhaust

Portion a Duct to the blower

Adding Cover Plate to Rear of Cabinet Bottom Exhaust

Reconnect the cut

Bottom opening

Final Setup

To the left and right

Important Notes

Standard Reversibility KIT

Chrome door cap Chrome door hinge cap Inner door cap

Door Parts

Unplug the dryer from its electrical outlet

Remove the Door Assembly

Before YOU Start

Remove the side hinge cap by opening

Reverse Door Handle and Caps

Reverse Door Handle and Caps

Reverse Hinge and Caps

Put the chrome cover aside on a soft, protected flat surface

Reverse Front Panel Plug Buttons and Strike Plate

Reassemble Door Assembly

Reinstall Door Assembly

Screws #10 x 0.75″ tapping screws

Before YOU Begin

Install Rubber Pads to Dryer Base

KIT Contents

Installation Preparation

Finalize the Installation

Install Bracket to Dryer

Install Dryer and Bracket on Washer

Set the dryer upright

Phillips-head

Remove the Leveling Legs

Support pads Drawer divider Mounting screws

Screwdriver

For Dryers only

Install the Pedestal to the Washer or Dryer

Prepare the Pedestal

Remove Shipping Screws

Reinstall the Drawer

Level the Washer or Dryer

Check to Be sure the slides are closed Slide the drawer

Before you call for service…

Possible Causes What To Do

Time Remaining

Power button was activated

Replace both fuses or reset both breakers. Your dryer

This is normal

Clothes shrink

When washed. Others can be

Procedures before drying

To avoid shrinkage, follow garment care labels exactly

Select a shorter cycle. Manually reduce cycle time

Install rubber washer provided with hose

Small amount of water

Tighten connection

Page

For The Period Of We Will Replace

What Is Not Covered in the United States

Safety Instructions

Warrantor General Electric Company. Louisville, KY

For The Period

What Is Not Covered in Canada

We Will Replace

Modèle N Série N

Conduit d’évacuation

’installation et les réparations doivent

Qualifié, une entreprise de réparation

Gardez tous les produits pour la lessive comme

Ne montez jamais sur le dessus de la sécheuse

Ne trafiquez pas les commandes de l’appareil

Et le chargement en

Démarrage

Timed Dry séchage minuté

Propos du panneau de contrôle de la sécheuse

Dry Cycles cycles de séchage

Sensor Dry Level détection du niveau d’humidité

Statut du cycle spécial OU Grill

Dry Temp température de séchage

Display affichage

De séchage OU Séchage minuté

Literie et salle de bain

Specialty Cycles cycles spéciaux

Cycles reliés à la laveuse

Autres articles spéciaux

Drum Light Lumière du tambour

Delay Start Mise en marche différée

Options de cycle

Lock Verrouillage

Lumière de tambour

Settings Réglage

Propos des caractéristiques de la sécheuse

« Built-In Rack Dry System »

Reverse TumbleMC

Sélectionnez le temps désiré Appuyez sur la touche

Étiquettes de séchage

Utilisation de la sécheuse

Étiquettes d’entretien de tissu

Entretien et nettoyage

Pour Votre Sécurité

DPVH890 et UPVH890

Avant DE Commencer

Pour LES Modèles À GAZ Uniquement

Dimensions DE LA Sécheuse

Instructions d’installation

Emplacement DE Votre Sécheuse

Déballage DE Votre Sécheuse

Installation Dans UNE Salle DE Bain OU UNE Chambre

Exigences Relatives UNE Installation Encastrée

Installation Dans UNE Maison Mobile OU Préfabriquée

M2 120 po carrés

Branchement DES Boyaux D’ARRIVÉE

Exigences DE L’ALIMENTATION D’EAU

Niveau Clé à tuyau 8 po Pince à joint coulissant

Outils Nécessaires

Matériel Nécessaire Pour Votre Sécurité

Lunettes de protection

Dans LE Commonwealth DU Massachusetts

Exigences Relatives AU GAZ

Alimentation EN GAZ

Raccordement DE L’ALIMENTATION EN GAZ DE LA Sécheuse

Raccordement DE LA Sécheuse À L’ALIMENTATION EN GAZ

Raccordement DE LA Sécheuse À L’ALIMENTATION EN GAZ Suite

Détection DES Fuites

La procédure de détection de fuites

Si nécessaire Gants ’event d’évacuation Ruban adhésif

Tournevis à tête plate Niveau

Lunettes de protection Tuyau métallique

La prise murale de votre domicile avant d’acheter le cordon

NE Laissez Jamais LE Couvercle Enlevé

Instructions DE Mise À LA Terre

La borne de mise à la terre sur la sécheuse

DE LA Plaque À Bornes

Raccordement DE LA Sécheuse À L’AIDE D’UN Câble À 3 Fils

NE Laissez Jamais LE Couvercle Enlevé DE LA Plaque À Bornes

Séparations DES Coudes

Le risque d’incendie et de blessure

Évent Mural

Étanchéité DES Joints

Coupez

’INSTALLEZ PAS

NE Faites PAS

’ÉCRASEZ PAS

QUE DES Conduits DE Métal

Instructions d’installation Évacuation DE LA Sécheuse suite

LONGUEURDUTUYAUD’ÉCHAPPEMENT

Typesdecouvertsdetuyaud’échappement

De ruban en toile

Évacuation Arrière Standard

Enlevez toute charpie de l’ouverture d’évacuation murale

Évacuation Latérale

Emplacement DE LA Languette

Avant DE Procéder À L’INSTALLATION

Ajouter UN Nouveau Conduit

Ajouter UNE Plaque D’OBTURATION

Avant DE Procéder a L’INSTALLATION

Évacuation PAR LE Dessous

DE Gants

’intérieur de la sécheuse lors de l’insertion du conduit

Installation Finale

Toutes les vis doivent être vissées à la main

Remarques Importantes

Ensemble D’INVERSION Standard

Capuchons

#8 x 0,375 po

Pièces DE LA Porte

Couvre-charnière Couvercle de porte chromé

11 #8 x 0,625 po

Débranchez la sécheuse de sa prise électrique

Comment Retirer LA Porte

Comment Démonter LA Porte

Sur une surface plane, lisse et protégée

Comment Inverser LA Poignée ET LES Couvercles DE LA Porte

Vis taraudeuses #8 x 0,75 po

Comment Inverser LA Charnière ET LES Couvercles

Mastic ou un tournevis à fine lame

Comment Inverser

Comment Réinstaller LA Porte

Comment Réinstaller LA Porte

LES Capuchons ET LA Gâche DU Panneau Avant

Comment Superposer LA Sécheuse À LA Laveuse optionnel

Contenu DE L’ENSEMBLE

Tournevis cruciforme Gants Clé à fourche

Ne pas masquer le panneau de contrôle de la laveuse

Comment Installer LE Support SUR LA Sécheuse

Comment Installer LA Sécheuse ET LE Support SUR LA Laveuse

Corporelle potentielle. Ne poussez pas sur

’INSTALLATION Doit Être Effectuée PAR Deux Personnes

Instructions d’installation Installation DU Socle optionnel

Comment Préparer L’INSTALLATION

Contenu D’ENSEMBLE

Pour LES Sécheuses Uniquement

Comment Installer LE Socle SUR LA Laveuse OU LA Sécheuse

Comment Préparer LE Socle

Saisissez-vous des 4 cales de support

Comment Mettre LA Laveuse OU LA Sécheuse DE Niveau

Comment Réinstaller LE Tiroir

Comment Terminer L’INSTALLATION

Vérifiez si

Avant d’appeler un réparateur…

Problème Causes possibles Correctifs

Restant n’est pas affiché. L’option de culbutage

La sécheuse émet Temperature ou l’OPTION Un double bip

Mais 00 est le temps

Chauffe lorsque l’alimentation en gaz est restaurée

Avant le séchage

’autres peuvent être lavés

La machine ou ne le séchez pas dans la sécheuse

Par exemple

Une rondelle de caoutchouc

’eau sont retrouvées

La durée du cycle pour ledit cycle

Garant General Electric Company. Louisville, KY

Nous remplacerons

Ce qui n’est pas couvert au les États-Unis

Pour une période de

Ce qui n’est pas couvert

Garantie de la sécheuse GE. Pour des clients au Canada

Pour une période de Nous remplacerons

Fonctionnement

Soutien au consommateur

De bureau

Modelo # Serie #

La instalación y servicio técnico deben

Vapores o líquidos inflamables cerca

De este o cualquier otro artefacto

Salida al exterior/Conductos

De funcionamiento

Nunca se suba o pare sobre la secadora

Un cable o enchufe dañados

Se encuentran cubiertos por la garantía de este artefacto

El botón START/PAUSE

Sobre el panel de control de la secadora

Inicio rápido

Soporte al consumidor

Dry Cycles ciclos de secado

START/PAUSE inicio/pausa

Clean Lint Filter message limpiar filtro de pelusas mensaje

Dry Temp temperatura de secado

My Cycle mi ciclo en algunos modelos

Los ciclos especiales Specialty Cycles incluyen Prendas

Specialty Cycles ciclos especiales

Ciclos con comunicación con la lavadora

Cama y baño

Drum Light luz del tambor

Sobre las opciones de ciclo

Damp Alert alerta de humedad

Lock bloqueo

Lámpara del tambor

Settings configuraciones

Sobre las características de la secadora

Built-In Rack Dry System sistema de tendedero incorporado

Reverse Tumble Secado reverso

Secado por tendedero accesorio opcional

Cómo usar el gancho incorporado para colgar prendas

Calor bajo

Etiquetas sobre cuidado

Cómo usar la secadora

Consejos de clasificación y carga

De las telas

Antes DE Comenzar

DPVH890 y UPVH890

Advertencia

Para SU Seguridad

Cómo Desempacar LA Secadora

Dimensiones DE LA Secadora

Instrucciones de instalación

27″″ 68.,6 cm

Requerimientos Para Instalación EN Nichos O Armarios

Instalación EN Baños Dormitorios

Instalación EN Casas Móviles Prefabricadas

El material del conducto de ventilación

Requisitos DE Suministro DE Agua

Cómo Conectar Mangueras DE Entrada

Cómo Conectar Mangueras DE Entrada

Materiales Necesarios Para SU Seguridad

Cómo Conectar UNA Secadora a GAS

Herramientas Necesarias

Suministro DE GAS

Requerimientos DE GAS

Conexión DE Suministro DE GAS DE LA Secadora

EN LA Mancomunidad DE Massachusetts

Cómo Conectar LA Secadora AL Suministro DE GAS

Cierre la válvula de apagado del gas

Advertencia Nunca utilice

Cómo Conectar UNA Secadora Electrica

Si se cuenta con una secadora a gas, saltear este paso

Advertencia Para reducir

Clasificado UL De 120/240V, 30A con

Destornillador de lados

Planos

Requerimientos Eléctricos Para Secadoras Eléctricas

123

Salida AL Exterior DE LA Secadora

Lista DE Control DEL Sistema DE Salida

No Haga LO Siguiente

Codos

Tipos de campana de salida

Advertencia Sólo USE

Longitud DE Salida

Giros QUE no SON DE 90º

Recomendamos instalar la secadora antes

Salida Trasera Estándar

Quite las pelusas de la abertura de salida de la pared

Cómo Agregar UN Conducto Nuevo

Ventilación Lateral

Ubicación DE LA Lengüeta

Corte el conducto como puede verse y conserve la porción a

Ventilación Lateral

Salida POR LA Parte Inferior

De seguridad

Configuración Final

Notas Importantes

KIT Estándar DE Reversibilidad

Pequeño

Piezas DE LA Puerta

Tapa de la bisagra Cubierta de puerta de cromo

Tapa de puerta de cromo

Desenchufe la secadora del tomacorriente

Quite EL Montaje DE LA Puerta

Desarme EL Montaje DE LA Puerta

Sostenga la puerta y quite los 2 tornillos

Cómo Invertir LA Manija Y LAS Tapas DE LA Puerta

Tornillos tornillos auto-roscantes #8 x 0.625″

Cómo Invertir LA Manija LAS Tapas DE LA Puerta

Cómo Invertir LAS Bisagras Y Tapas

Coloque la puerta en el panel frontal

Cómo Volver a Colocar EL Montaje DE LA Puerta

Cómo Reinstalar EL Montaje DE LA Puerta

Tornillos tornillos auto-roscantes #10 x 0.75″

EN Otros Espacios QUE no Sean Instalaciones EN Nichos

Espacio Libre Mínimo

Armarios

Lesiones personales potenciales

Cómo Quitar LAS Patas Niveladoras DE LA Secadora

Contenidos DEL KIT

Instale Almohadillas DE Goma EN LA Base DE LA Secadora

Cómo Instalar LA Secadora Y EL Soporte EN LA Lavadora

Finalice LA Instalación

Cómo Instalar EL Soporte EN LA Secadora

Coloque la secadora en posición vertical

Preparación Para LA Instalación

Cómo Quitar LAS Patas

Niveladoras

SE Necesitan DOS Personas Para Realizar

Cómo Instalar EL Pedestal EN LA Lavadora O Secadora

Prepare EL Pedestal

Sólo Para Secadoras

Cómo Volver a Instalar EL Cajón

Cómo Nivelar LA Lavadora O Secadora

Quite LOS Tornillos DE Empaque

Del cajón

Problema Causas posibles Solución

Antes de llamar al servicio de asistencia técnica…

La carga sigue húmeda

Clean Lint Filter

Secado DRY seco pero

No se ven números

146

Puerta y sobre el filtro

No pueden verse las

Se ve agua dentro de la

Húmedas después del

Notas

No se encuentra cubierto en Canadá

Garantía de la secadora GE. Para clientes de Canadá

Por el período de Reemplazaremos

Garante General Electric Company. Louisville, KY

Período Se sustituirá

Exclusiones de la garantía

El período de tiempo más breve permitido por la ley

Apoyo al cliente

Programe una reparación

Consumer Support

Canada, contact Manager, Consumer Relations, Mabe Canada Inc