—If the wheels are properly aligned, the straightedge will touch both inside gauge blocks and there will be a

Figure 46. Overhead view of straightedge on

blade wheel gauge blocks.

—If the wheels are not positioned as shown above, determine which direction they need to move in order to be correct, then proceed to Step 7 to begin the adjustment process.

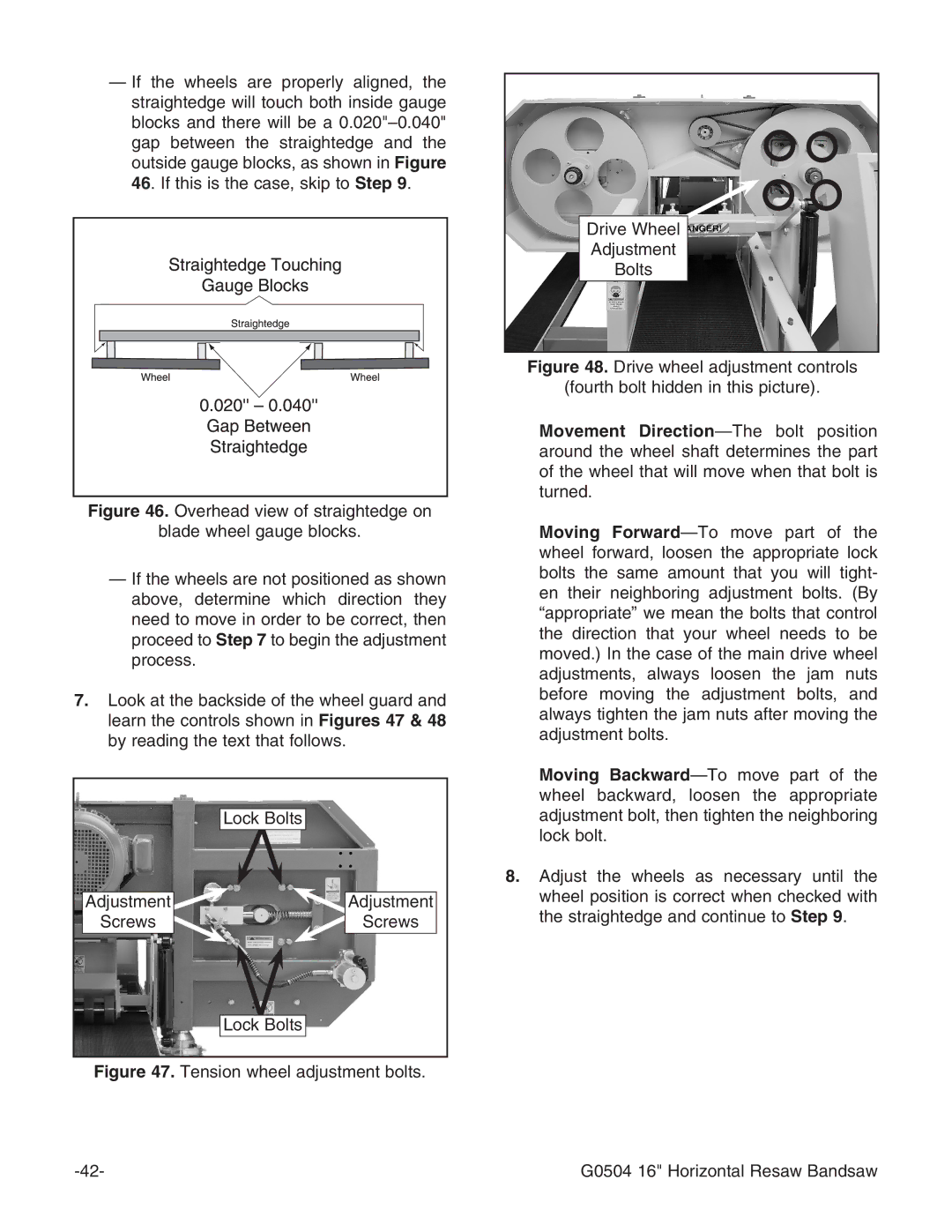

7.Look at the backside of the wheel guard and learn the controls shown in Figures 47 & 48 by reading the text that follows.

Drive Wheel

Adjustment

Bolts

Figure 48. Drive wheel adjustment controls

(fourth bolt hidden in this picture).

Movement Direction—The bolt position around the wheel shaft determines the part of the wheel that will move when that bolt is turned.

Moving Forward—To move part of the wheel forward, loosen the appropriate lock bolts the same amount that you will tight- en their neighboring adjustment bolts. (By “appropriate” we mean the bolts that control the direction that your wheel needs to be moved.) In the case of the main drive wheel adjustments, always loosen the jam nuts before moving the adjustment bolts, and always tighten the jam nuts after moving the adjustment bolts.

| Lock Bolts |

| 8. |

Adjustment | Adjustment |

Screws | Screws |

| Lock Bolts |

Figure 47. Tension wheel adjustment bolts.

Moving Backward—To move part of the wheel backward, loosen the appropriate adjustment bolt, then tighten the neighboring lock bolt.

Adjust the wheels as necessary until the wheel position is correct when checked with the straightedge and continue to Step 9.

G0504 16" Horizontal Resaw Bandsaw |