Lubrication

Bearings: The bearings are sealed and pre- lubricated; they require no lubrication.

Trunnions: Use

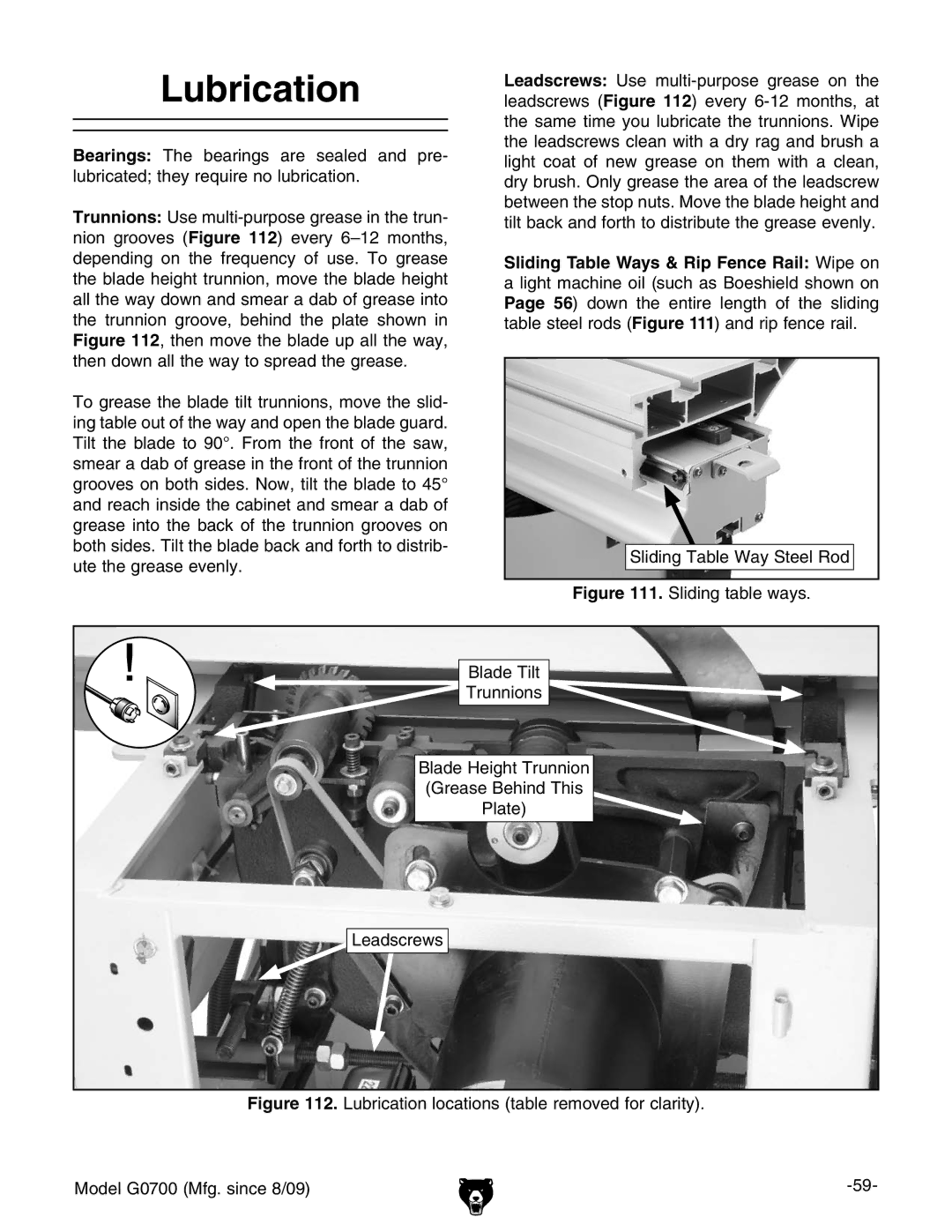

To grease the blade tilt trunnions, move the slid- ing table out of the way and open the blade guard. Tilt the blade to 90°. From the front of the saw, smear a dab of grease in the front of the trunnion grooves on both sides. Now, tilt the blade to 45° and reach inside the cabinet and smear a dab of grease into the back of the trunnion grooves on both sides. Tilt the blade back and forth to distrib- ute the grease evenly.

Leadscrews: Use

Sliding Table Ways & Rip Fence Rail: Wipe on a light machine oil (such as Boeshield shown on Page 56) down the entire length of the sliding table steel rods (Figure 111) and rip fence rail.

Sliding Table Way Steel Rod

Figure 111. Sliding table ways.

Blade Tilt |

Trunnions |

Blade Height Trunnion |

(Grease Behind This |

Plate) |

Leadscrews |

Figure 112. Lubrication locations (table removed for clarity).

Model G0700 (Mfg. since 8/09) |