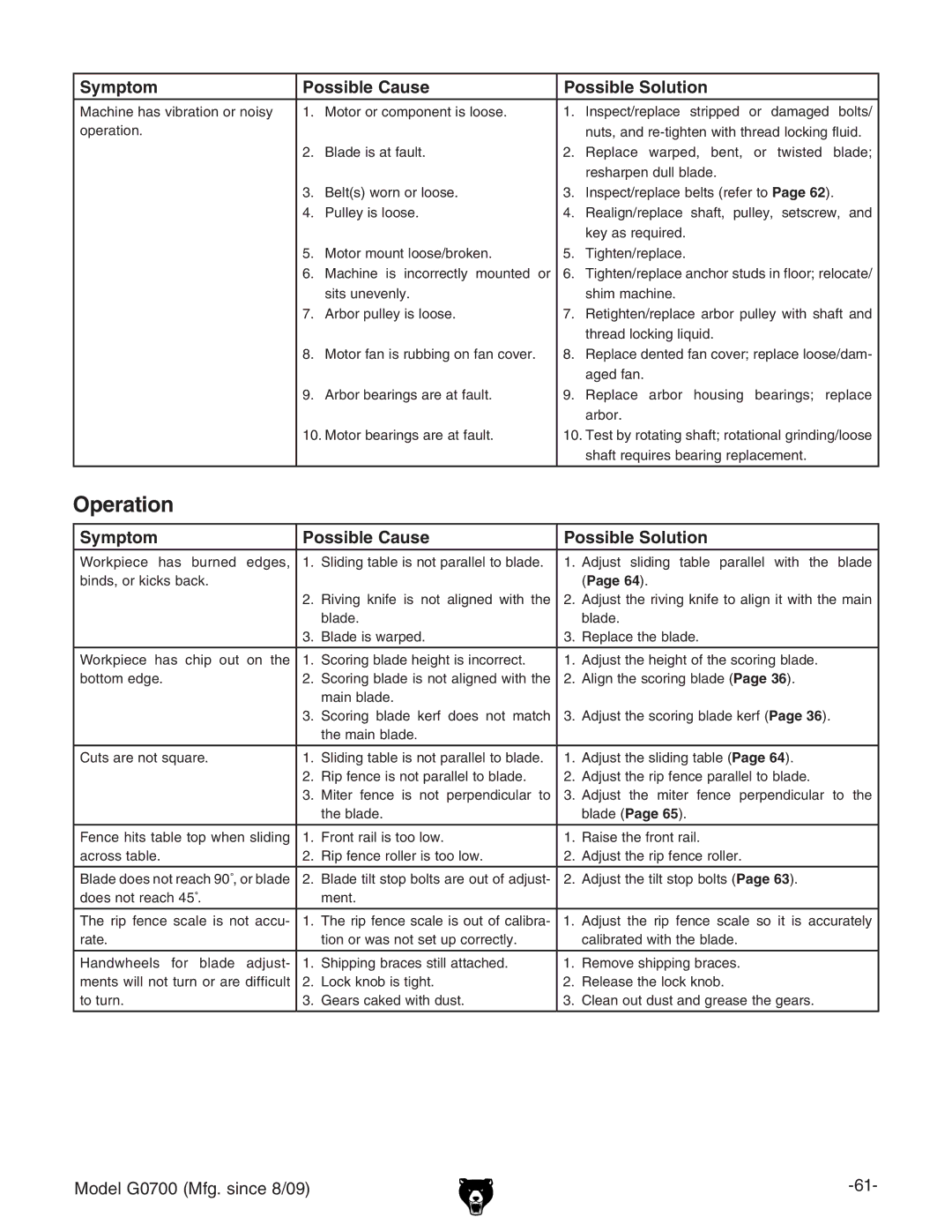

Symptom | Possible Cause | Possible Solution | ||

Machine has vibration or noisy | 1. | Motor or component is loose. | 1. | Inspect/replace stripped or damaged bolts/ |

operation. |

|

|

| nuts, and |

| 2. | Blade is at fault. | 2. | Replace warped, bent, or twisted blade; |

|

|

|

| resharpen dull blade. |

| 3. | Belt(s) worn or loose. | 3. | Inspect/replace belts (refer to Page 62). |

| 4. | Pulley is loose. | 4. | Realign/replace shaft, pulley, setscrew, and |

|

|

|

| key as required. |

| 5. | Motor mount loose/broken. | 5. | Tighten/replace. |

| 6. | Machine is incorrectly mounted or | 6. | Tighten/replace anchor studs in floor; relocate/ |

|

| sits unevenly. |

| shim machine. |

| 7. | Arbor pulley is loose. | 7. | Retighten/replace arbor pulley with shaft and |

|

|

|

| thread locking liquid. |

| 8. | Motor fan is rubbing on fan cover. | 8. | Replace dented fan cover; replace loose/dam- |

|

|

|

| aged fan. |

| 9. | Arbor bearings are at fault. | 9. | Replace arbor housing bearings; replace |

|

|

|

| arbor. |

| 10. Motor bearings are at fault. | 10. Test by rotating shaft; rotational grinding/loose | ||

|

|

|

| shaft requires bearing replacement. |

|

|

|

|

|

Operation

Symptom | Possible Cause | Possible Solution | ||

Workpiece has burned edges, | 1. | Sliding table is not parallel to blade. | 1. | Adjust sliding table parallel with the blade |

binds, or kicks back. |

|

|

| (Page 64). |

| 2. | Riving knife is not aligned with the | 2. | Adjust the riving knife to align it with the main |

|

| blade. |

| blade. |

| 3. | Blade is warped. | 3. | Replace the blade. |

|

|

|

|

|

Workpiece has chip out on the | 1. | Scoring blade height is incorrect. | 1. | Adjust the height of the scoring blade. |

bottom edge. | 2. | Scoring blade is not aligned with the | 2. | Align the scoring blade (Page 36). |

|

| main blade. |

|

|

| 3. | Scoring blade kerf does not match | 3. | Adjust the scoring blade kerf (Page 36). |

|

| the main blade. |

|

|

|

|

|

|

|

Cuts are not square. | 1. | Sliding table is not parallel to blade. | 1. | Adjust the sliding table (Page 64). |

| 2. | Rip fence is not parallel to blade. | 2. | Adjust the rip fence parallel to blade. |

| 3. | Miter fence is not perpendicular to | 3. | Adjust the miter fence perpendicular to the |

|

| the blade. |

| blade (Page 65). |

|

|

|

|

|

Fence hits table top when sliding | 1. | Front rail is too low. | 1. | Raise the front rail. |

across table. | 2. | Rip fence roller is too low. | 2. | Adjust the rip fence roller. |

|

|

|

|

|

Blade does not reach 90˚, or blade | 2. | Blade tilt stop bolts are out of adjust- | 2. | Adjust the tilt stop bolts (Page 63). |

does not reach 45˚. |

| ment. |

|

|

|

|

|

| |

The rip fence scale is not accu- | 1. | The rip fence scale is out of calibra- | 1. Adjust the rip fence scale so it is accurately | |

rate. |

| tion or was not set up correctly. |

| calibrated with the blade. |

|

|

|

| |

Handwheels for blade adjust- | 1. | Shipping braces still attached. | 1. Remove shipping braces. | |

ments will not turn or are difficult | 2. | Lock knob is tight. | 2. | Release the lock knob. |

to turn. | 3. | Gears caked with dust. | 3. Clean out dust and grease the gears. | |

|

|

|

|

|

Model G0700 (Mfg. since 8/09) |