4.Rout a

![]()

![]()

Figure 81. Slot routed in featherboard.

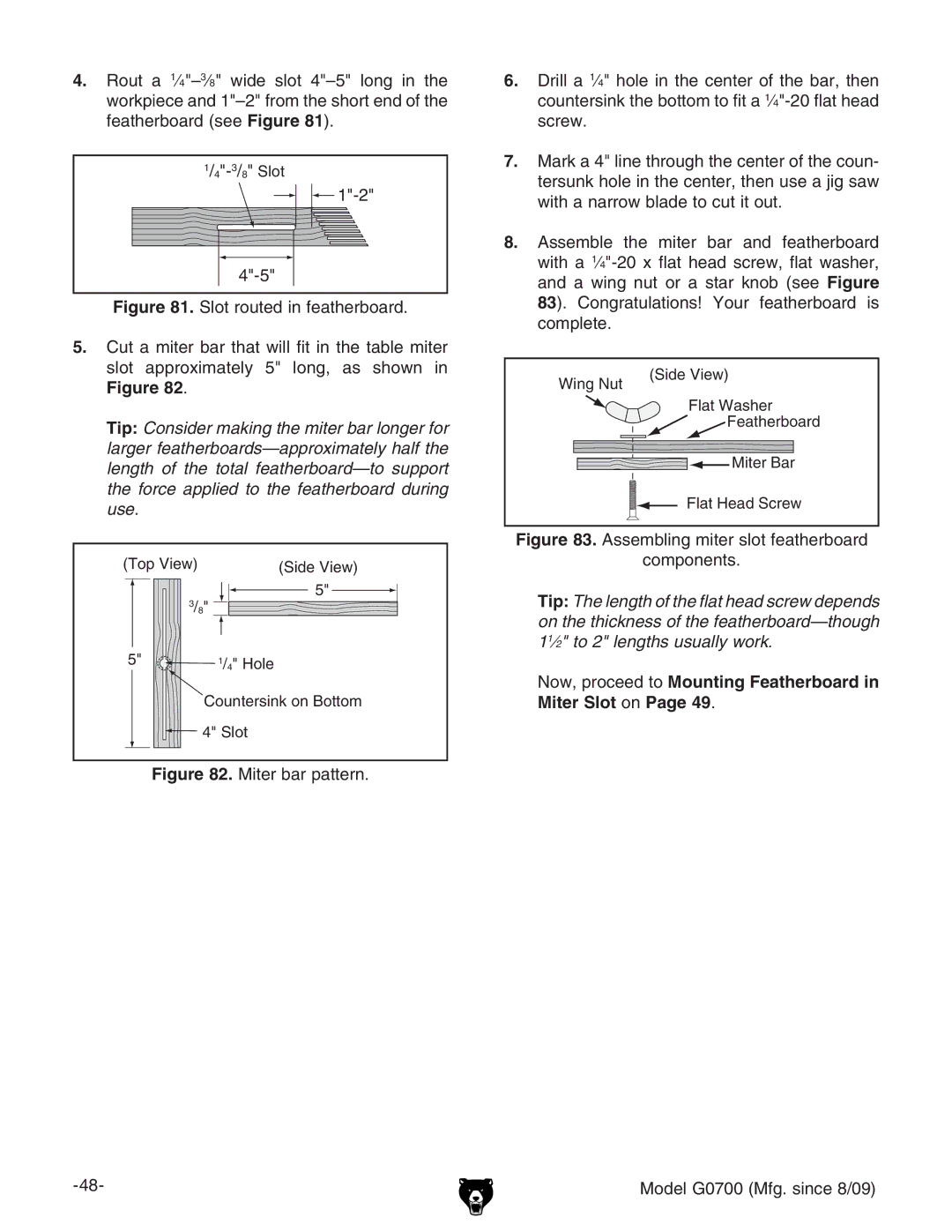

5.Cut a miter bar that will fit in the table miter slot approximately 5" long, as shown in

Figure 82.

Tip: Consider making the miter bar longer for larger

(Top View) |

| (Side View) |

3/8" |

| 5" |

|

| |

5" | 1 | /4" Hole |

|

|

Countersink on Bottom

![]() 4" Slot

4" Slot

Figure 82. Miter bar pattern.

6.Drill a 1⁄4" hole in the center of the bar, then countersink the bottom to fit a 1⁄4"-20 flat head screw.

7.Mark a 4" line through the center of the coun- tersunk hole in the center, then use a jig saw with a narrow blade to cut it out.

8.Assemble the miter bar and featherboard with a 1⁄4"-20 x flat head screw, flat washer, and a wing nut or a star knob (see Figure 83). Congratulations! Your featherboard is complete.

Wing Nut | (Side View) |

| |

| Flat Washer |

| Featherboard |

| Miter Bar |

| Flat Head Screw |

Figure 83. Assembling miter slot featherboard

components.

Tip: The length of the flat head screw depends on the thickness of the

Now, proceed to Mounting Featherboard in Miter Slot on Page 49.

Model G0700 (Mfg. since 8/09)