End Gears

Grease Type | T23964 or NLGI#2 Equivalent |

Lubrication | Every 50 Operating Hours |

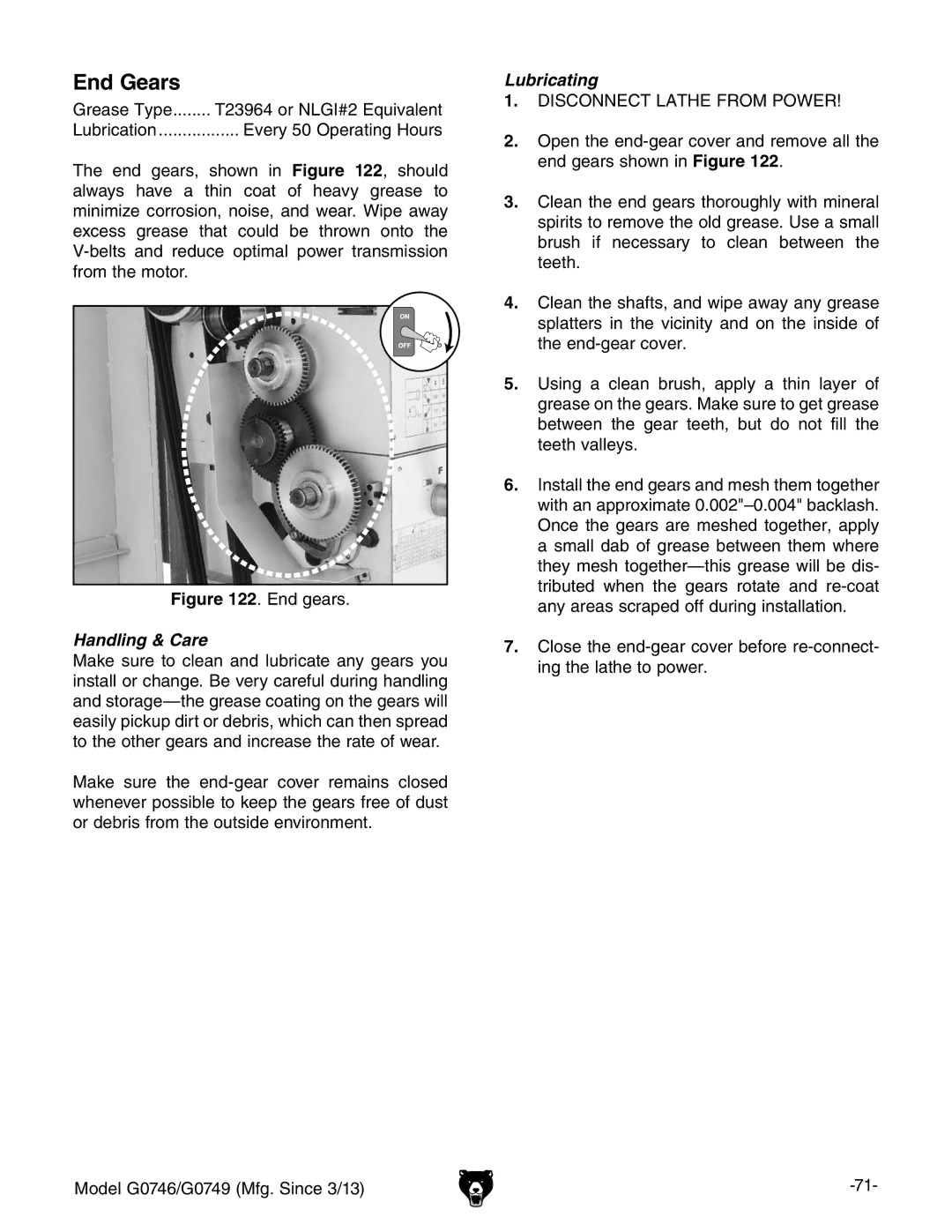

The end gears, shown in Figure 122, should always have a thin coat of heavy grease to minimize corrosion, noise, and wear. Wipe away excess grease that could be thrown onto the

Figure 122. End gears.

Handling & Care

Make sure to clean and lubricate any gears you install or change. Be very careful during handling and

Make sure the

Model G0746/G0749 (Mfg. Since 3/13)

Lubricating

1.DISCONNECT LATHE FROM POWER!

2.open the

3.Clean the end gears thoroughly with mineral spirits to remove the old grease. Use a small brush if necessary to clean between the teeth.

4.Clean the shafts, and wipe away any grease splatters in the vicinity and on the inside of the

5.Using a clean brush, apply a thin layer of grease on the gears. Make sure to get grease between the gear teeth, but do not fill the teeth valleys.

6.install the end gears and mesh them together with an approximate

7.Close the