Replacing Brake

1. DISCONNECT LATHE FROM POWER!

2.Open the

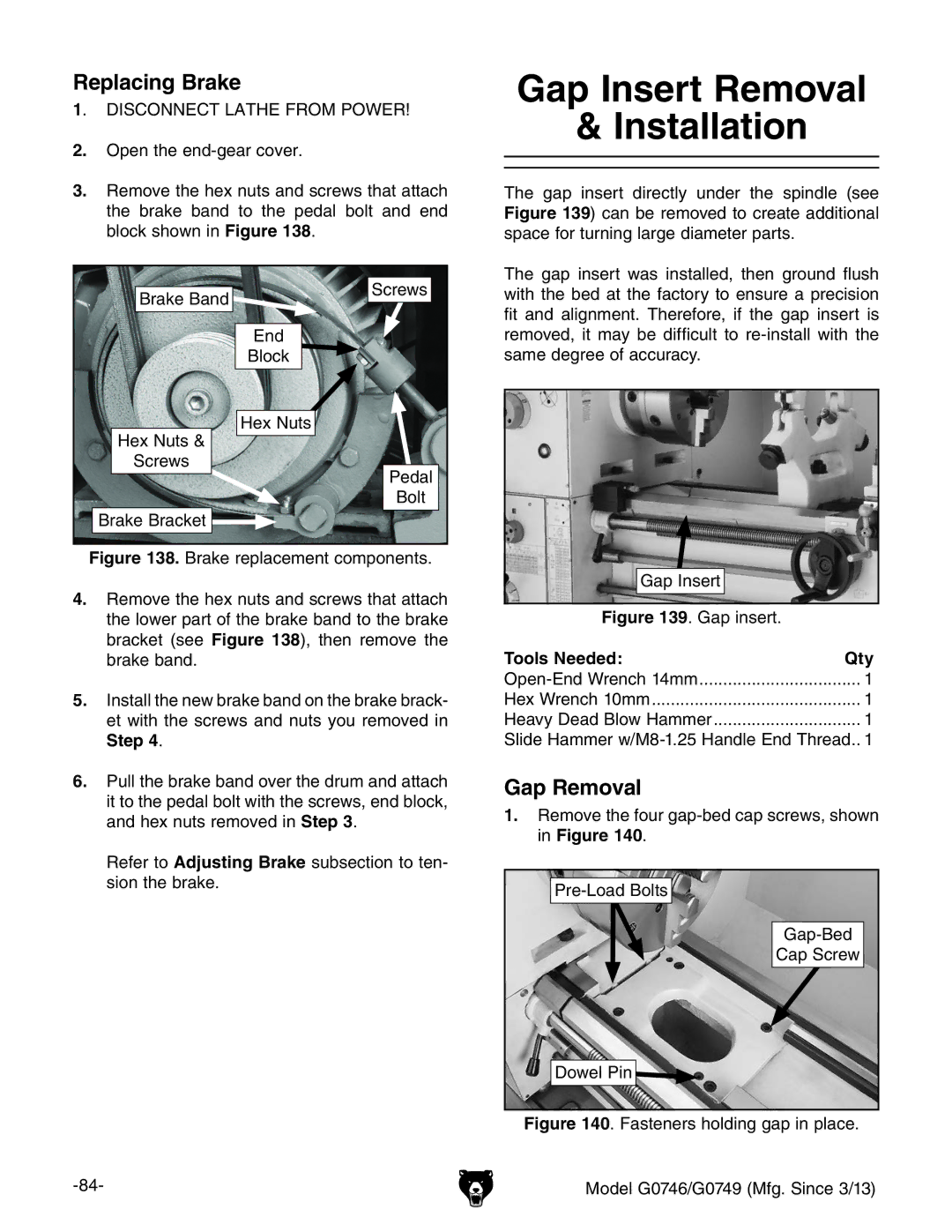

3.Remove the hex nuts and screws that attach the brake band to the pedal bolt and end block shown in Figure 138.

Brake Band | Screws |

| |

| End |

| Block |

Hex Nuts & | Hex Nuts |

| |

Screws | Pedal |

| |

| Bolt |

Brake Bracket |

|

Figure 138. Brake replacement components.

4.Remove the hex nuts and screws that attach the lower part of the brake band to the brake bracket (see Figure 138), then remove the brake band.

5.install the new brake band on the brake brack- et with the screws and nuts you removed in Step 4.

6.pull the brake band over the drum and attach it to the pedal bolt with the screws, end block, and hex nuts removed in Step 3.

Refer to Adjusting Brake subsection to ten- sion the brake.

Gap Insert Removal

& Installation

The gap insert directly under the spindle (see Figure 139) can be removed to create additional space for turning large diameter parts.

The gap insert was installed, then ground flush with the bed at the factory to ensure a precision fit and alignment. Therefore, if the gap insert is removed, it may be difficult to

Gap Insert |

|

Figure 139. Gap insert. |

|

Tools Needed: | Qty |

1 | |

Hex Wrench 10mm | 1 |

Heavy Dead Blow Hammer | 1 |

Slide Hammer | |

Gap Removal

1.Remove the four

Cap Screw

Dowel Pin![]()