Leadscrew End-Play

Adjustment

After a long period of time, you may find that the leadscrew develops excessive end play. This lathe is designed so that end play can be removed with a simple adjustment.

Items Needed | Qty |

Spanner Wrench | 1 |

To remove leadscrew end play: |

|

1.disCONNECT LATHE FROM POWER.

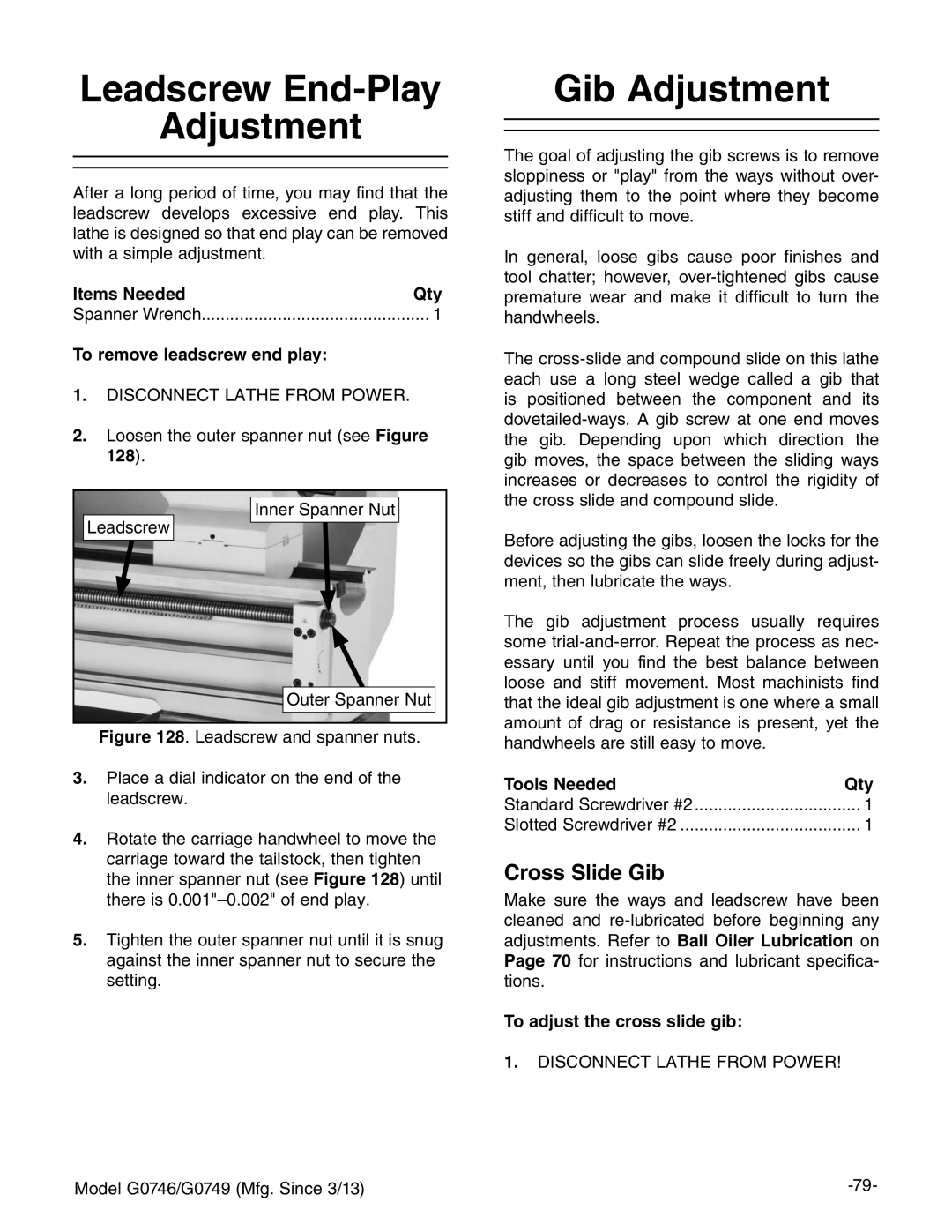

2.loosen the outer spanner nut (see Figure 128).

Inner Spanner Nut

Leadscrew

Outer Spanner Nut

Figure 128. Leadscrew and spanner nuts.

3.place a dial indicator on the end of the leadscrew.

4.Rotate the carriage handwheel to move the carriage toward the tailstock, then tighten the inner spanner nut (see Figure 128) until there is 0.001"–0.002" of end play.

5.tighten the outer spanner nut until it is snug against the inner spanner nut to secure the setting.

Model G0746/G0749 (Mfg. Since 3/13)

Gib Adjustment

The goal of adjusting the gib screws is to remove sloppiness or "play" from the ways without over- adjusting them to the point where they become stiff and difficult to move.

In general, loose gibs cause poor finishes and tool chatter; however,

The

Before adjusting the gibs, loosen the locks for the devices so the gibs can slide freely during adjust- ment, then lubricate the ways.

The gib adjustment process usually requires some

Tools Needed | Qty |

Standard Screwdriver #2 | ................................... 1 |

Slotted Screwdriver #2 | 1 |

Cross Slide Gib

Make sure the ways and leadscrew have been cleaned and

To adjust the cross slide gib:

1.disCONNECT LATHE FROM POWER!