8.Use calipers to measure both ends of the workpiece.

the lathe 1⁄2 the distance of the amount of taper, as shown in the figure below.

Move tailstock toward |

front of lathe 1/2 the |

amount of taper. |

Looking down from above. |

Figure 53. Adjust tailstock toward the operator.

—if the test stock is thinner at the tailstock end, move the tailstock toward the back of the lathe 1⁄2 the distance of the amount of taper, as shown in the figure below.

Looking down from above. |

Move tailstock toward |

back of lathe 1/2 the |

amount of taper. |

Figure 54. Adjust tailstock away from the

operator.

9.repeat Steps 6–8 until the desired accuracy is achieved.

Model G0746/G0749 (Mfg. Since 3/13)

Centers

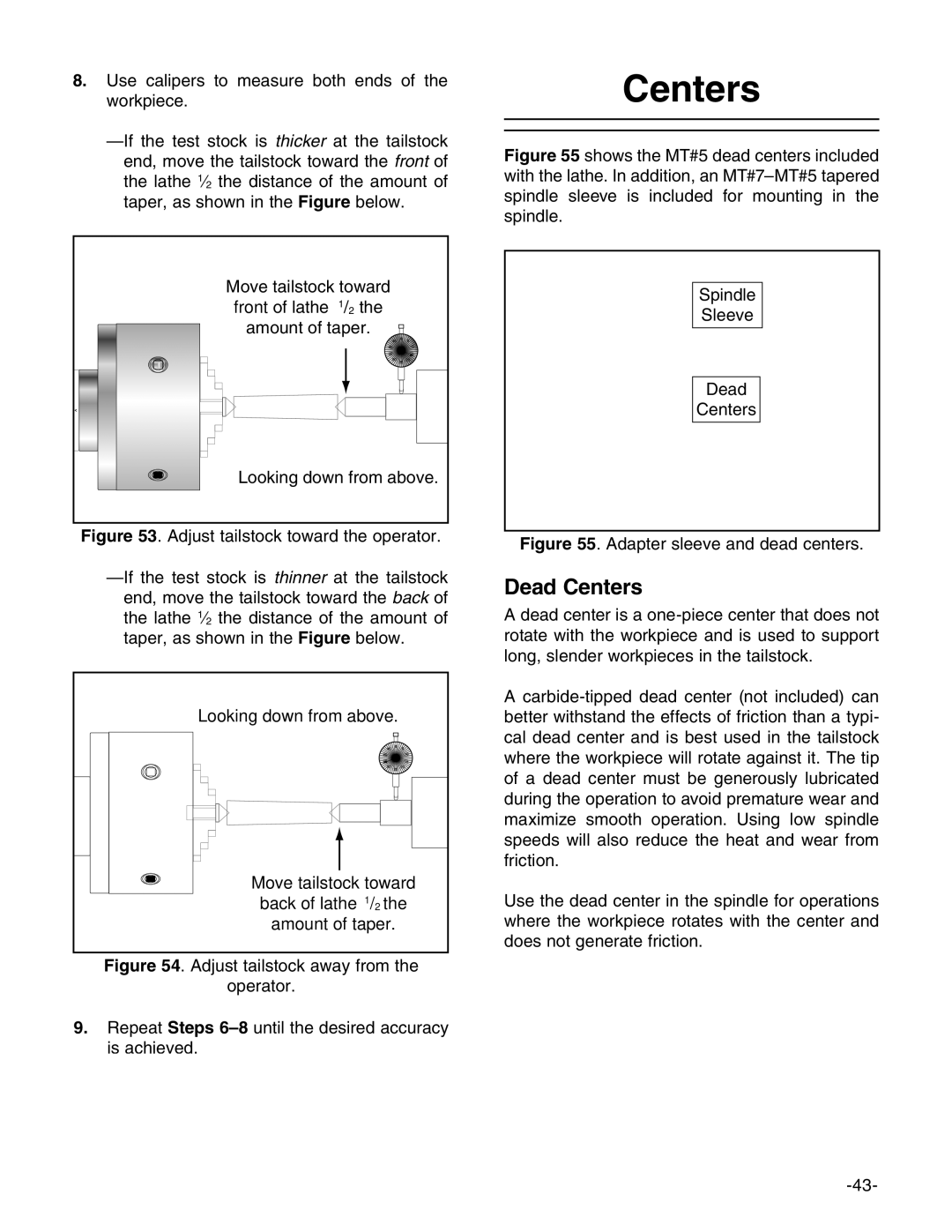

Figure 55 shows the MT#5 dead centers included with the lathe. In addition, an MT#7–MT#5 tapered spindle sleeve is included for mounting in the spindle.

Spindle

Sleeve

Dead

Centers

Figure 55. Adapter sleeve and dead centers.

Dead Centers

A dead center is a

A

Use the dead center in the spindle for operations where the workpiece rotates with the center and does not generate friction.