Anchoring to Floor |

| Leveling |

|

|

|

|

|

|

anchoring machinery to the floor prevents tipping or shifting and reduces vibration that may occur during operation, resulting in a machine that runs slightly quieter and feels more solid.

if the machine will be installed in a commercial or workplace setting, or if it is permanently connect- ed (hardwired) to the power supply, local codes may require that it be anchored to the floor.

if not required by any local codes, fastening the machine to the floor is an optional step. if you choose not to do this with your machine, we rec- ommend placing it on machine mounts, as these provide an easy method for leveling and they have

Anchoring to Concrete Floors

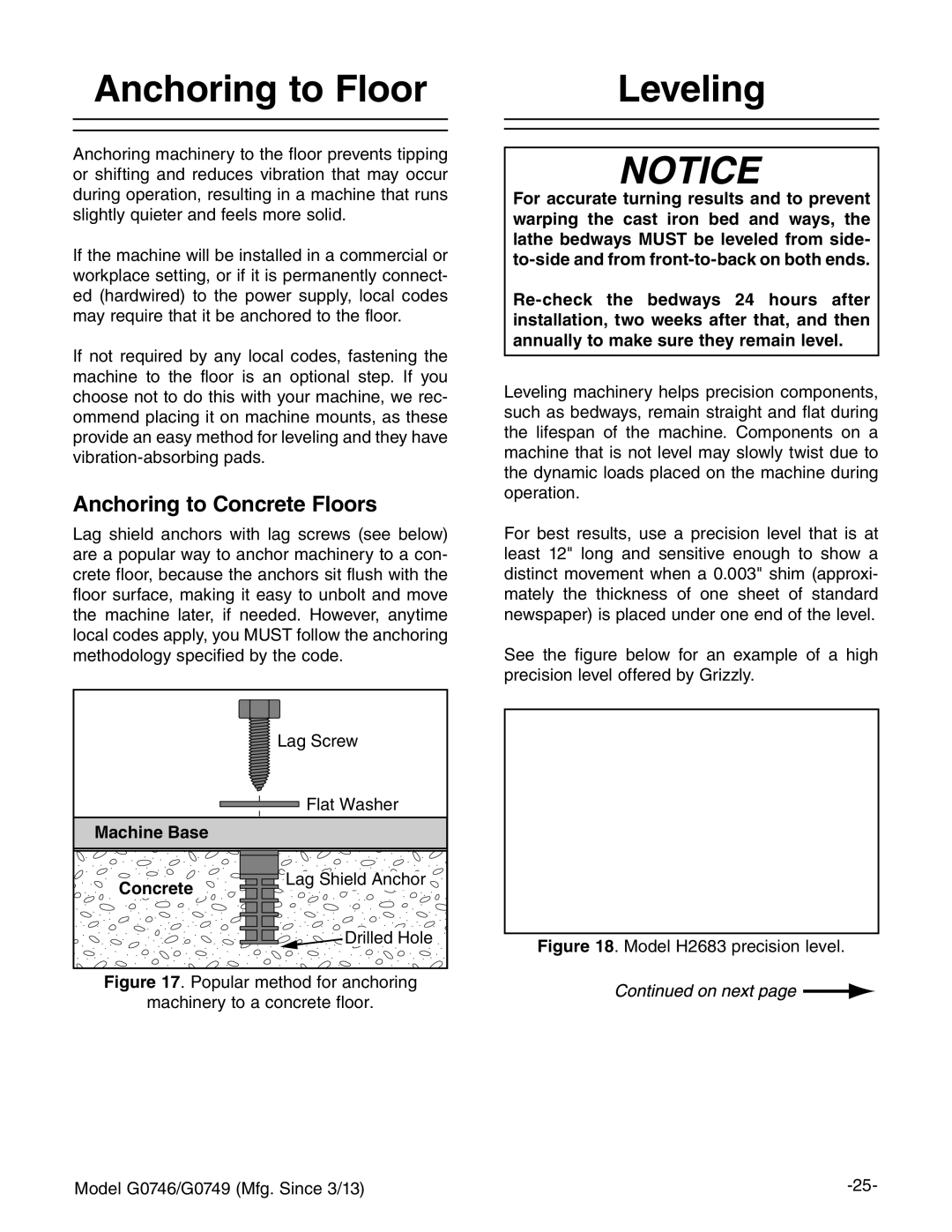

Lag shield anchors with lag screws (see below) are a popular way to anchor machinery to a con- crete floor, because the anchors sit flush with the floor surface, making it easy to unbolt and move the machine later, if needed. However, anytime local codes apply, you MUST follow the anchoring methodology specified by the code.

| Lag Screw |

| Flat Washer |

Machine Base |

|

Concrete | Lag Shield Anchor |

| |

| Drilled Hole |

Figure 17. Popular method for anchoring

machinery to a concrete floor.

Model G0746/G0749 (Mfg. Since 3/13)

For accurate turning results and to prevent warping the cast iron bed and ways, the lathe bedways MUST be leveled from side-

Leveling machinery helps precision components, such as bedways, remain straight and flat during the lifespan of the machine. Components on a machine that is not level may slowly twist due to the dynamic loads placed on the machine during operation.

For best results, use a precision level that is at least 12" long and sensitive enough to show a distinct movement when a 0.003" shim (approxi- mately the thickness of one sheet of standard newspaper) is placed under one end of the level.

See the figure below for an example of a high precision level offered by Grizzly.