Apron

Oil Type | Grizzly T23962 or ISO 68 Equivalent | |

Oil Amount | 6.5 Quarts | |

Check/Add Frequency | Daily | |

Change | Every 1000 Operating Hours | |

Checking Oil Level

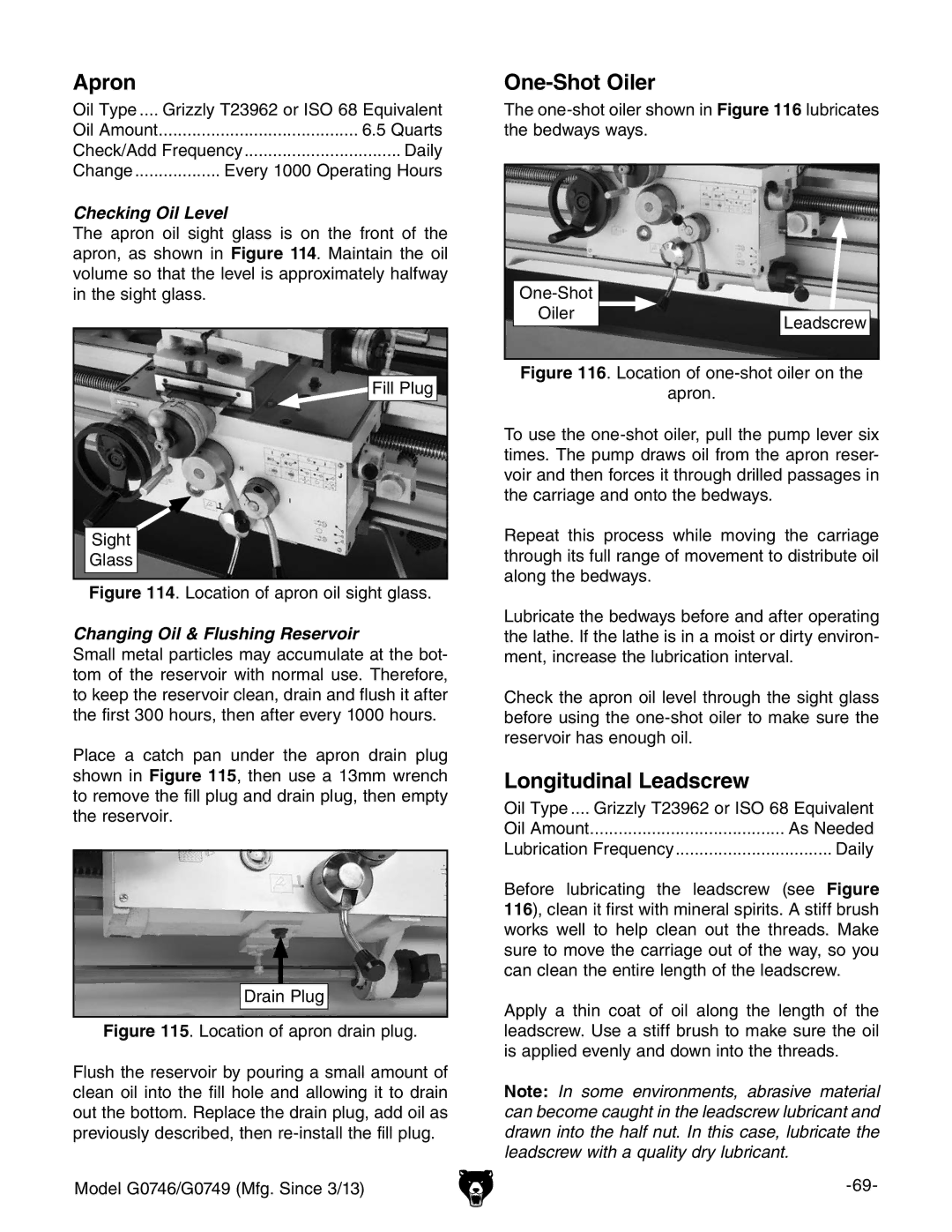

The apron oil sight glass is on the front of the apron, as shown in Figure 114. Maintain the oil volume so that the level is approximately halfway in the sight glass.

Fill Plug

Sight

Glass

Figure 114. Location of apron oil sight glass.

Changing Oil & Flushing Reservoir

Small metal particles may accumulate at the bot- tom of the reservoir with normal use. Therefore, to keep the reservoir clean, drain and flush it after the first 300 hours, then after every 1000 hours.

Place a catch pan under the apron drain plug shown in Figure 115, then use a 13mm wrench to remove the fill plug and drain plug, then empty the reservoir.

Drain Plug

Figure 115. Location of apron drain plug.

Flush the reservoir by pouring a small amount of clean oil into the fill hole and allowing it to drain out the bottom. Replace the drain plug, add oil as previously described, then re-install the fill plug.

Model G0746/G0749 (Mfg. Since 3/13)

One-Shot Oiler

The

| |

Oiler | Leadscrew |

|

Figure 116. Location of one-shot oiler on the

apron.

To use the one-shot oiler, pull the pump lever six times. The pump draws oil from the apron reser- voir and then forces it through drilled passages in the carriage and onto the bedways.

Repeat this process while moving the carriage through its full range of movement to distribute oil along the bedways.

Lubricate the bedways before and after operating the lathe. If the lathe is in a moist or dirty environ- ment, increase the lubrication interval.

Check the apron oil level through the sight glass before using the one-shot oiler to make sure the reservoir has enough oil.

Longitudinal Leadscrew

Oil Type..... Grizzly T23962 or ISO 68 Equivalent

Oil Amount | As Needed |

Lubrication Frequency | Daily |

Before lubricating the leadscrew (see Figure 116), clean it first with mineral spirits. A stiff brush works well to help clean out the threads. Make sure to move the carriage out of the way, so you can clean the entire length of the leadscrew.

Apply a thin coat of oil along the length of the leadscrew. Use a stiff brush to make sure the oil is applied evenly and down into the threads.

Note: In some environments, abrasive material can become caught in the leadscrew lubricant and drawn into the half nut. In this case, lubricate the leadscrew with a quality dry lubricant.