4-Jaw Chuck

refer to the chuck installation or chuck Removal sections for instructions on installing or removing the

the

because of the dynamic forces involved in machining a

Mounting Workpiece

1.disCoNNECt lathE FroM poWEr!

2.place a chuck cradle or plywood on the bed- way below the chuck to protect the bedway surfaces.

3.Use the chuck key to open each jaw so the workpiece will lay flat against the chuck face, jaw steps, or into the spindle opening.

4.With help from another person or a holding device, position the workpiece so it is cen- tered in the chuck.

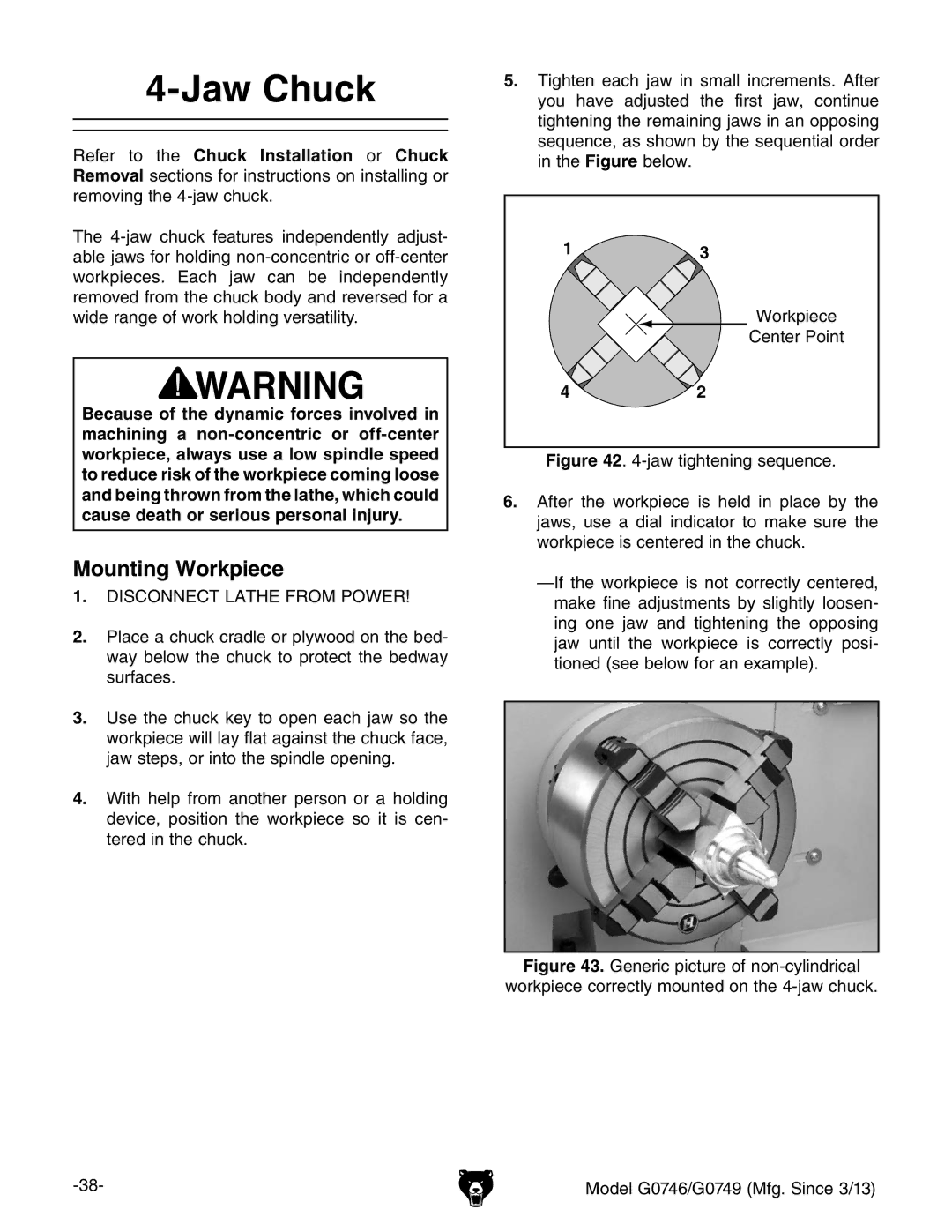

5.tighten each jaw in small increments. after you have adjusted the first jaw, continue tightening the remaining jaws in an opposing sequence, as shown by the sequential order in the figure below.

13

Workpiece

Center Point

42