5.incrementally tighten the camlocks in a criss- cross or star pattern to ensure that the chuck seats evenly against the spindle.

6.When the chuck is fully seated and all the camlocks are tight, verify that the cam line is between the two “V” marks on the spindle nose, as shown in the following figure.

Cam line between “V”s

Figure 34. Cam line positioned between the "V" marks after the camlocks are fully tightened.

—if the cam line is Not between the "V" marks when the camlock is tight, the stud may be installed at the incorrect height. to fix this, adjust the stud height as shown in the following figure. Make sure to re-install the stud cap screw afterward.

—if adjusting the stud height does not correct the problem, try swapping stud positions on the chuck.

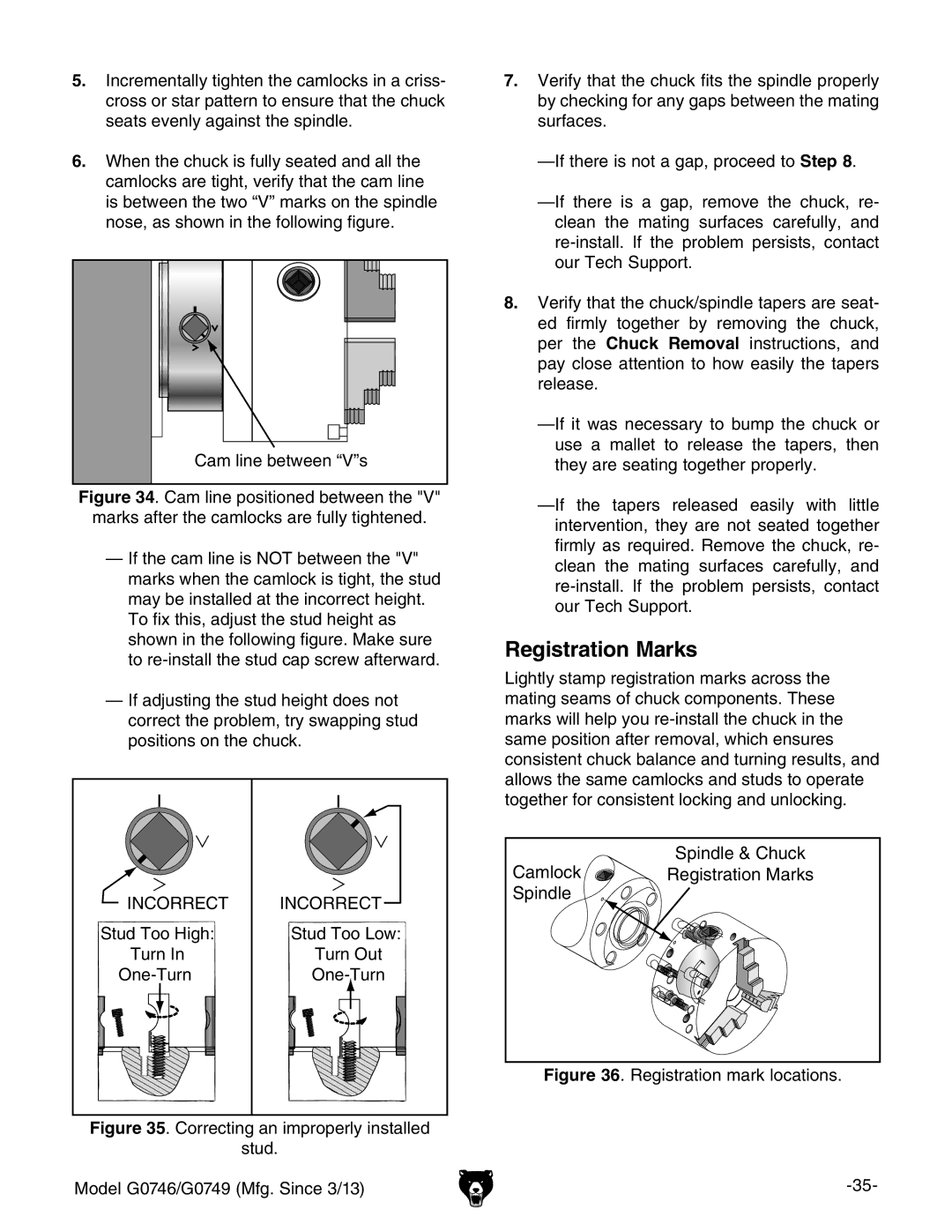

INCORRECT | INCORRECT |

Stud Too High: | Stud Too Low: |

Turn In | Turn Out |

Figure 35. Correcting an improperly installed

stud.

Model G0746/G0749 (Mfg. Since 3/13)

7.Verify that the chuck fits the spindle properly by checking for any gaps between the mating surfaces.

—if there is not a gap, proceed to Step 8.

—if there is a gap, remove the chuck, re- clean the mating surfaces carefully, and re-install. if the problem persists, contact our tech support.

8.Verify that the chuck/spindle tapers are seat- ed firmly together by removing the chuck, per the chuck Removal instructions, and pay close attention to how easily the tapers release.

—if it was necessary to bump the chuck or use a mallet to release the tapers, then they are seating together properly.

—if the tapers released easily with little intervention, they are not seated together firmly as required. remove the chuck, re- clean the mating surfaces carefully, and re-install. if the problem persists, contact our tech support.

Registration Marks

lightly stamp registration marks across the mating seams of chuck components. these marks will help you

Camlock | Spindle & Chuck |

Registration Marks | |

Spindle |

|