End-Gear Configuration Example

Follow the example below to better understand how to configure the end gears for inch threading.

Tools Needed | Qty |

Hex Wrench 6mm | 1 |

1 |

To configure end gears for threading 16 TPI:

1.Locate 16 TPI and the primary gear configu- ration on the thread chart (see Figure 83).

|

|

|

|

|

|

|

|

|

| Primary Gear |

|

|

|

|

| 16 TPI |

| |||

|

|

| Configuration |

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Figure 83. Locating change gears for 16 TPI.

2.disCONNECT LATHE FROM POWER!

3.remove the cap screw that secures the end- gear cover, then open it.

4.While holding the 36T and 72T change gears, loosen the arm support hex nut (see Figure 84).

Z1 | 72T Change | |

Combination | ||

Gear | ||

Gear | ||

| ||

36T Change | Z2 | |

Gear | Combination | |

| Gear | |

|

| |

Arm Support | Arm | |

Hex Nut | ||

Support | ||

|

Figure 84. Arm support and gear locations.

5.slowly let the gears pivot down until they rest against the V-belt guard (see Figure 84).

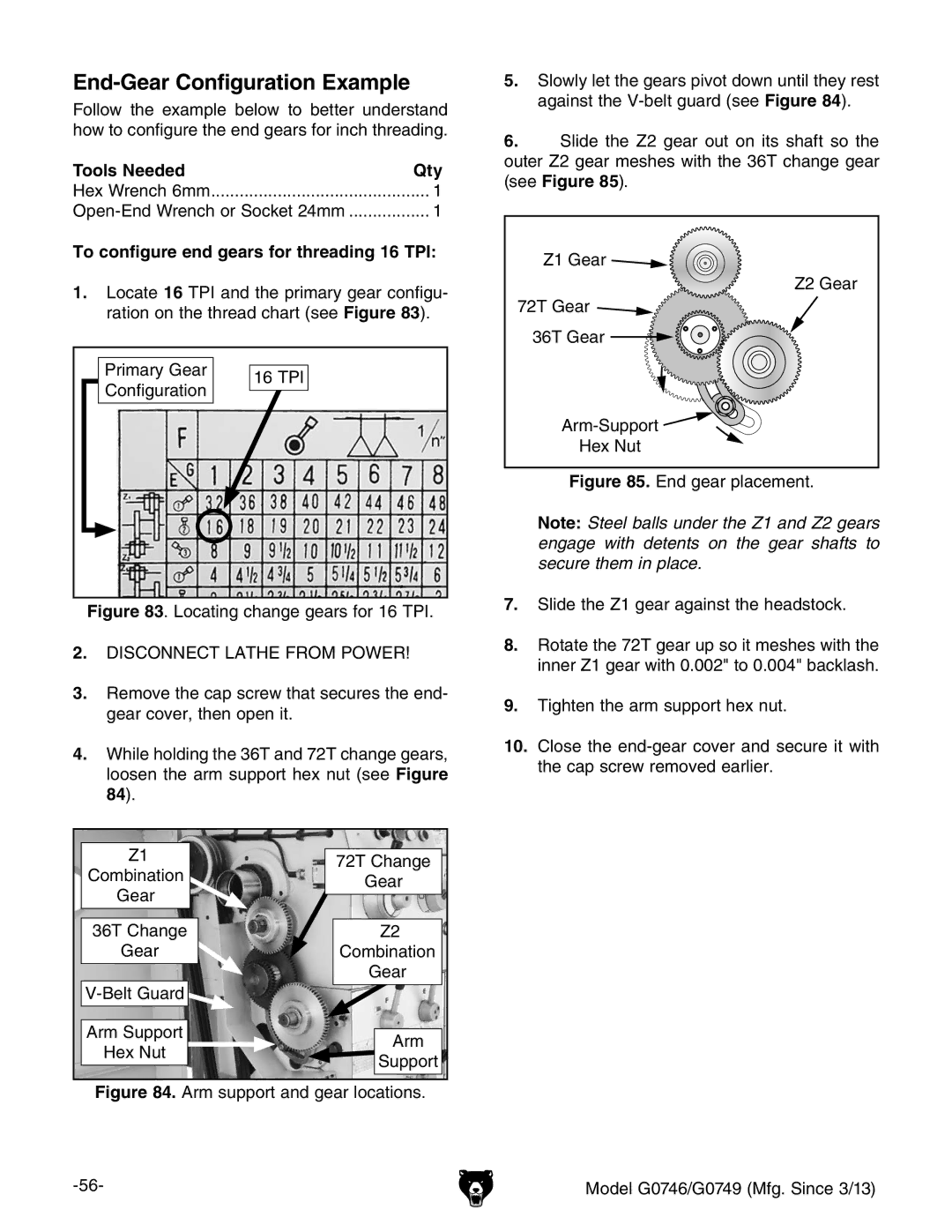

6.Slide the Z2 gear out on its shaft so the outer Z2 gear meshes with the 36T change gear (see Figure 85).

Z1 Gear

Z2 Gear

72T Gear

36T Gear

Arm-Support

Hex Nut

Figure 85. End gear placement.

Note: Steel balls under the Z1 and Z2 gears engage with detents on the gear shafts to secure them in place.

7.Slide the Z1 gear against the headstock.

8.rotate the 72T gear up so it meshes with the inner Z1 gear with 0.002" to 0.004" backlash.

9.tighten the arm support hex nut.

10.Close the end-gear cover and secure it with the cap screw removed earlier.

Model G0746/G0749 (Mfg. Since 3/13) |