Steady Rest

the steady rest supports long shafts and can be mounted anywhere along the length of the bed- way.

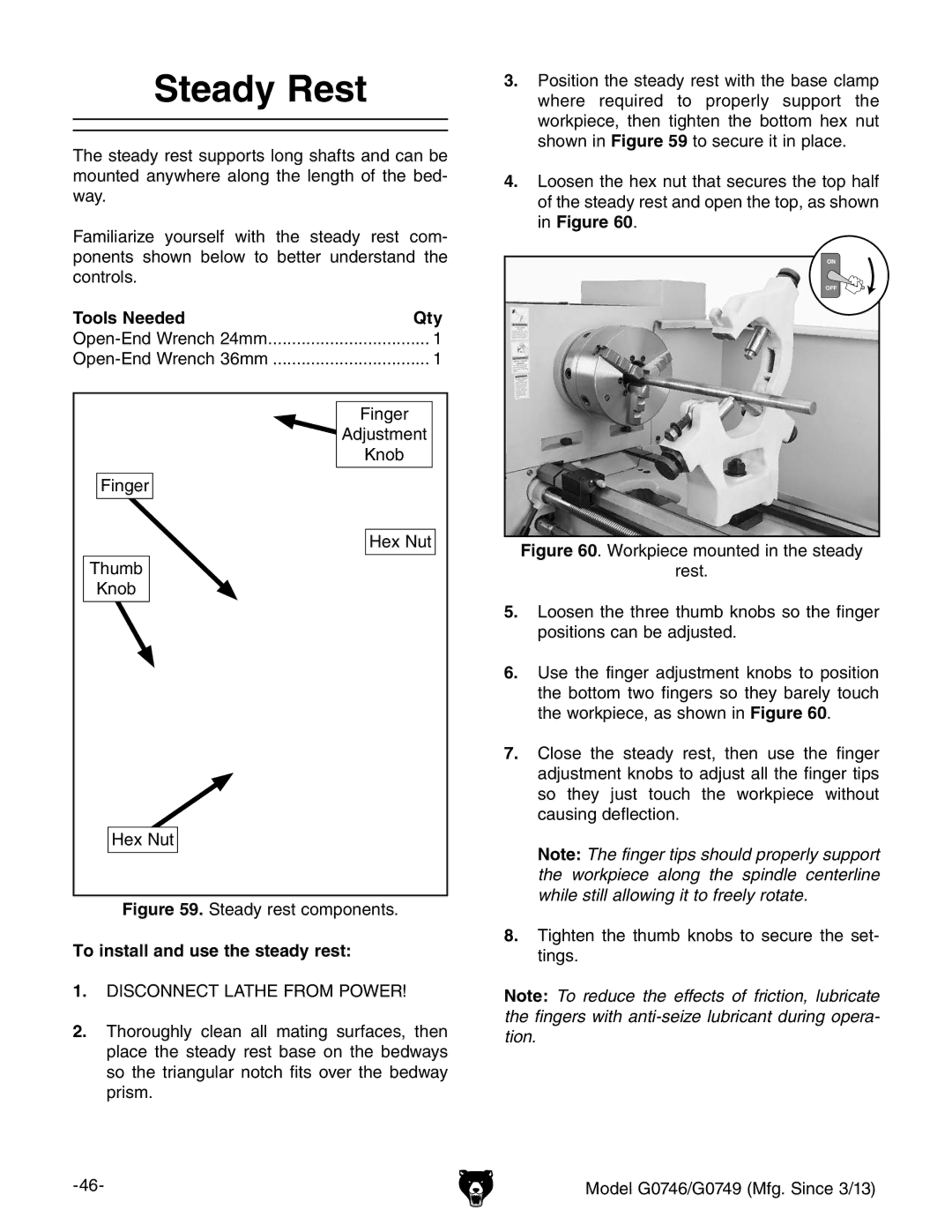

Familiarize yourself with the steady rest com- ponents shown below to better understand the controls.

Tools Needed | Qty |

................................. 1 | |

1 |

Finger |

Adjustment |

Knob |

Finger |

Hex Nut |

Thumb |

Knob |

Hex Nut |

Figure 59. Steady rest components.

To install and use the steady rest:

1.disCONNECT LAthE FROM POWER!

2.Thoroughly clean all mating surfaces, then place the steady rest base on the bedways so the triangular notch fits over the bedway prism.

3.Position the steady rest with the base clamp where required to properly support the workpiece, then tighten the bottom hex nut shown in Figure 59 to secure it in place.

4.loosen the hex nut that secures the top half of the steady rest and open the top, as shown in Figure 60.

Figure 60. Workpiece mounted in the steady

rest.

5.Loosen the three thumb knobs so the finger positions can be adjusted.

6.Use the finger adjustment knobs to position the bottom two fingers so they barely touch the workpiece, as shown in Figure 60.

7.Close the steady rest, then use the finger adjustment knobs to adjust all the finger tips so they just touch the workpiece without causing deflection.

Note: The finger tips should properly support the workpiece along the spindle centerline while still allowing it to freely rotate.

8.Tighten the thumb knobs to secure the set- tings.

Note: To reduce the effects of friction, lubricate the fingers with