Half Nut | Carriage Controls | |

|

|

|

|

|

|

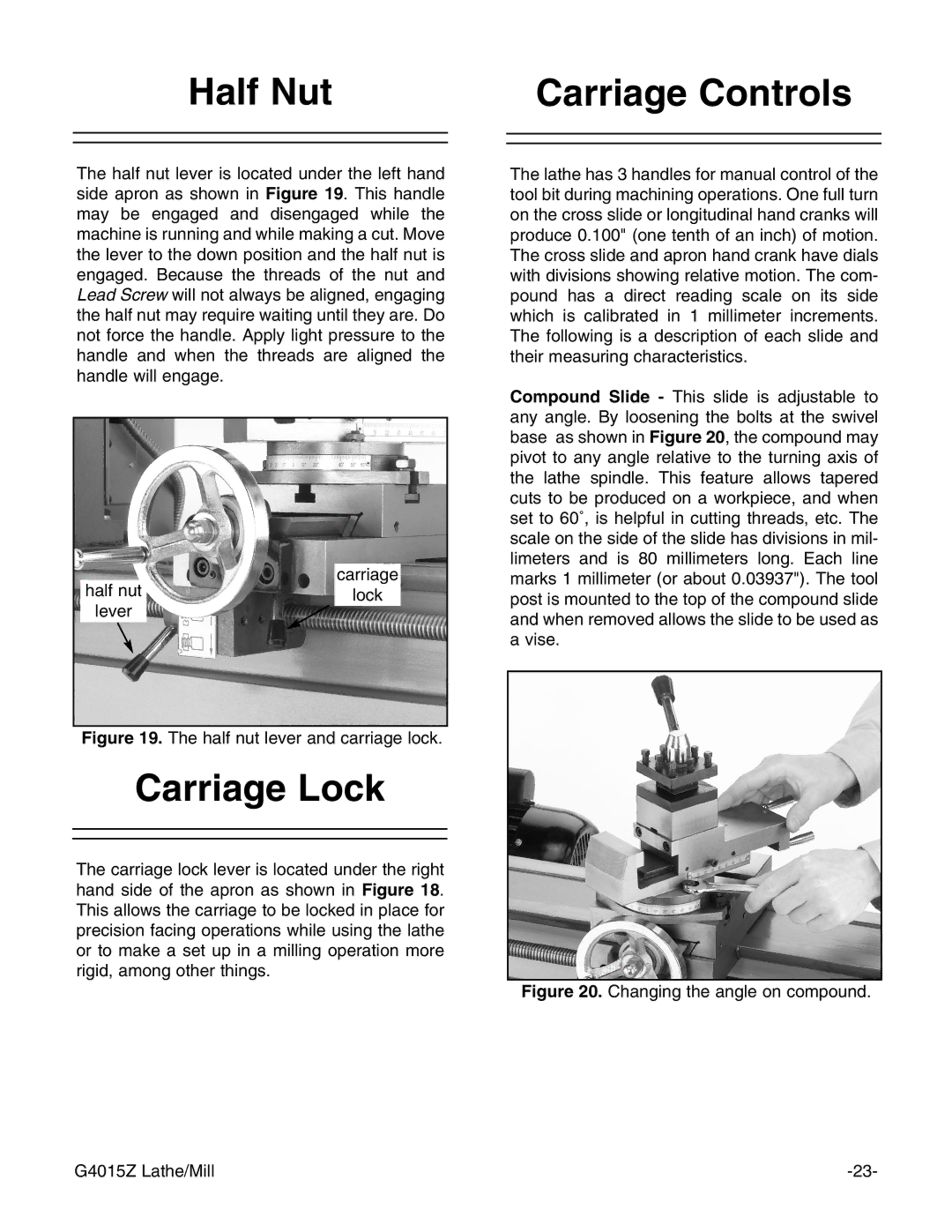

The half nut lever is located under the left hand side apron as shown in Figure 19. This handle may be engaged and disengaged while the machine is running and while making a cut. Move the lever to the down position and the half nut is engaged. Because the threads of the nut and Lead Screw will not always be aligned, engaging the half nut may require waiting until they are. Do not force the handle. Apply light pressure to the handle and when the threads are aligned the handle will engage.

carriage

half nutlock lever

The lathe has 3 handles for manual control of the tool bit during machining operations. One full turn on the cross slide or longitudinal hand cranks will produce 0.100" (one tenth of an inch) of motion. The cross slide and apron hand crank have dials with divisions showing relative motion. The com- pound has a direct reading scale on its side which is calibrated in 1 millimeter increments. The following is a description of each slide and their measuring characteristics.

Compound Slide - This slide is adjustable to any angle. By loosening the bolts at the swivel base as shown in Figure 20, the compound may pivot to any angle relative to the turning axis of the lathe spindle. This feature allows tapered cuts to be produced on a workpiece, and when set to 60˚, is helpful in cutting threads, etc. The scale on the side of the slide has divisions in mil- limeters and is 80 millimeters long. Each line marks 1 millimeter (or about 0.03937"). The tool post is mounted to the top of the compound slide and when removed allows the slide to be used as a vise.

Figure 19. The half nut lever and carriage lock.

Carriage Lock

The carriage lock lever is located under the right hand side of the apron as shown in Figure 18. This allows the carriage to be locked in place for precision facing operations while using the lathe or to make a set up in a milling operation more rigid, among other things.

Figure 20. Changing the angle on compound.

G4015Z Lathe/Mill |