Metric Threading

The metric threading gear chart is illustrated in Figure 49. The layout is listed below to help iden- tify gears for cutting threads with metric pitches. The chart below lists threads in millimeters or the theoretical amount of space one thread occupies.

| 1 |

|

|

|

| mm |

|

| 4 |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |

2 | D |

|

| I |

|

|

| II |

|

A | 24 | 25 | 30 | 60 | 24 | 30 | 60 | B=120 | |

|

| ||||||||

| 24 |

|

|

| 0.4 |

| 0.4 | 0.2 |

|

| 27 |

|

|

|

|

| 0.45 |

|

|

| 30 |

|

|

| 0.5 |

|

| 0.25 |

|

| 36 | 1.5 |

|

| 0.6 | 0.75 |

| 0.3 |

|

3 | 42 | 1.75 |

|

| 0.7 |

|

| 0.35 |

|

| 60 | 2.5 |

| 2 |

| 1.25 | 1 |

|

|

| 75 |

| 3 |

|

|

|

|

|

|

Figure 49. Rates given in millimeters and inches.

Please note that charts reflect approximate apron movement per revolution.

1.The column of numbers below D represent the number of teeth on gears used in position D.

2.The numbers to the right of A represent the number of teeth on gears used in position A.

3.Field of possible thread pitches.

4.This gear will always have 120 teeth and will be intermediate to gears A and D.

Example:

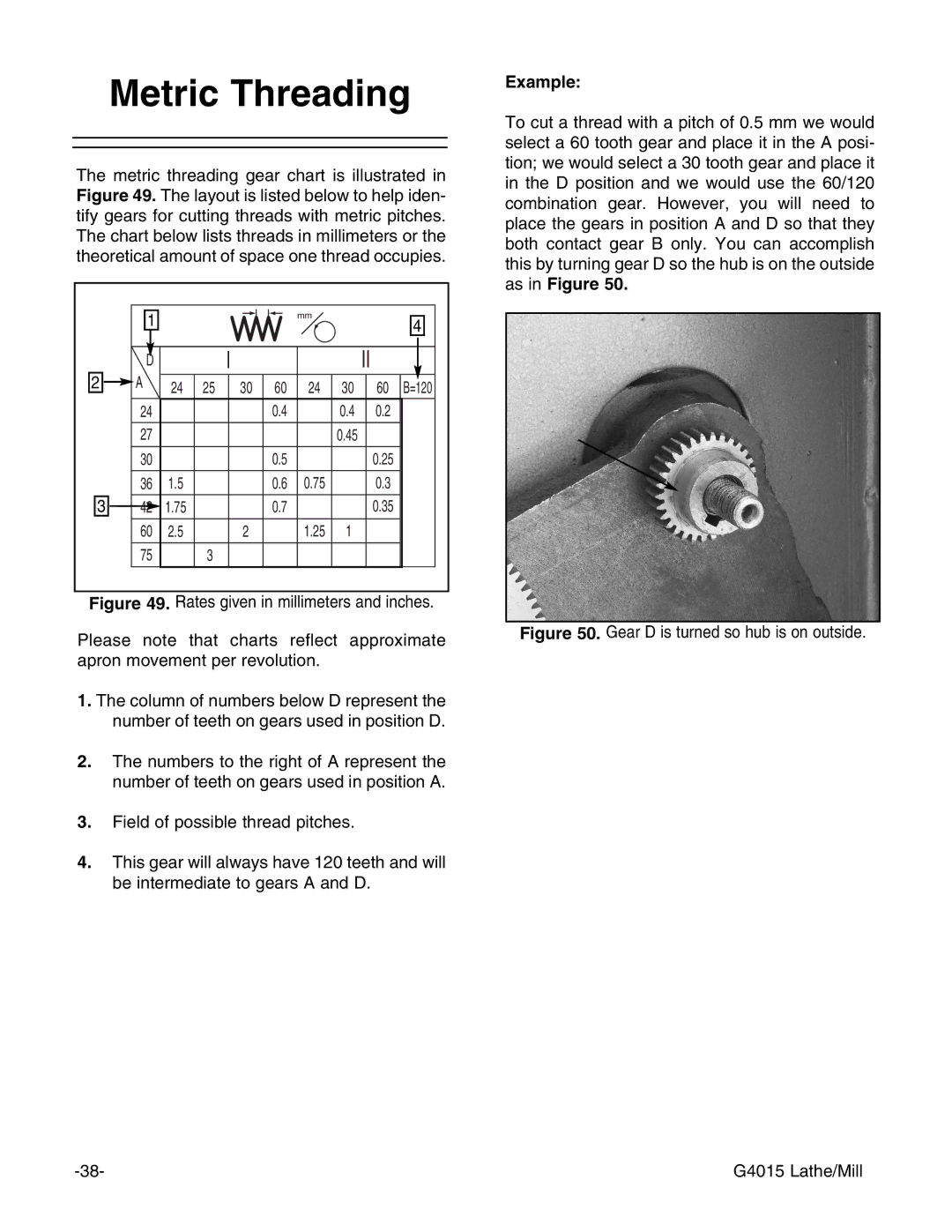

To cut a thread with a pitch of 0.5 mm we would select a 60 tooth gear and place it in the A posi- tion; we would select a 30 tooth gear and place it in the D position and we would use the 60/120 combination gear. However, you will need to place the gears in position A and D so that they both contact gear B only. You can accomplish this by turning gear D so the hub is on the outside as in Figure 50.

Figure 50. Gear D is turned so hub is on outside.

G4015 Lathe/Mill |