SECTION 8: ADJUSTMENTS

Gibs

There are three gib adjustments for the Model G4015Z. They are: the

The gib is held in place by the setscrews. Do not over tighten. The gib is properly adjusted when a slight drag is detected while turning the hand crank. This drag should be evenly distributed among the 4 setscrews, so adjust each so a slight drag is detected while the hand crank is turned. The large setscrew in the middle of the slide can be tightened to lock the slide in place.

NOTICE

When adjusting gibs, keep in mind that the goal of gib adjustment is to remove unneces- sary sloppiness from the slides movement without causing them to bind. Loose gibs may cause poor finishes on the workpiece and undue wear on the slide. Over tightening may cause premature wear on the slide, Lead Screw and nut.

Compound Gib - The gib on the compound has 2 setscrews to maintain tension on the slide. These setscrews are held in place with retaining nuts. To adjust, loosen the retaining nuts and then tighten the setscrews as needed. When proper tension has been detected by turning the hand crank on the compound, tighten the retain- ing nuts while maintaining the position of the setscrew with an Allen® wrench as in Figure 29.

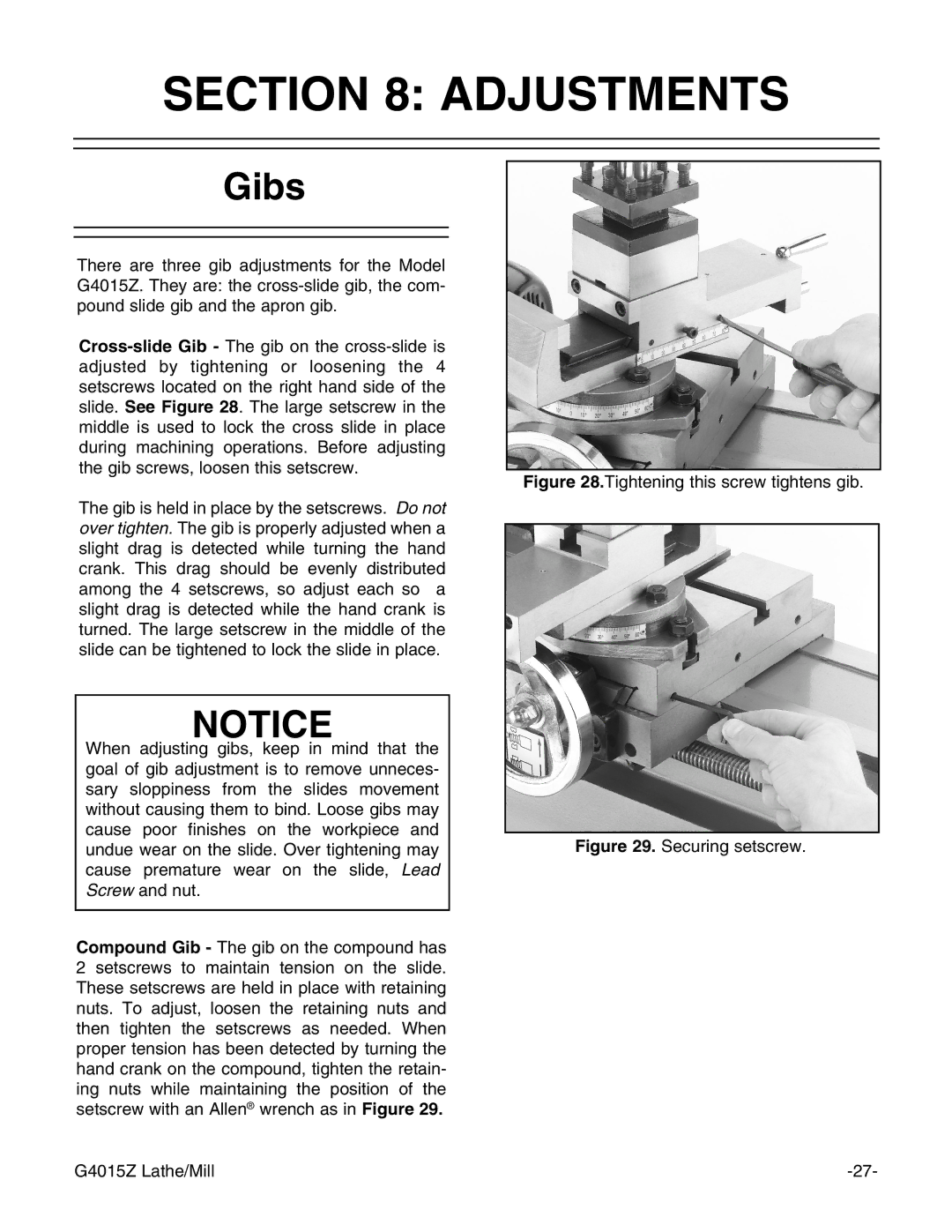

Figure 28.Tightening this screw tightens gib.

Figure 29. Securing setscrew.

G4015Z Lathe/Mill |