SECTION 10: MAINTENANCE

Disconnect power to the machine when perform- ing any adjustments or maintenance. Failure to do this may result in seri- ous personal injury.

Lubrication

Your Model G4015Z will function best when it is clean and well lubricated. Take the time to wipe down and oil the machine before each use. We recommend using ISO 68 or SAE 20W non- detergent oil unless otherwise specified. Ball fit- tings will require the use of an oil gun. Depress the ball with the tip of the gun and squirt a little oil under pressure. Make sure to clean the machine after each use.

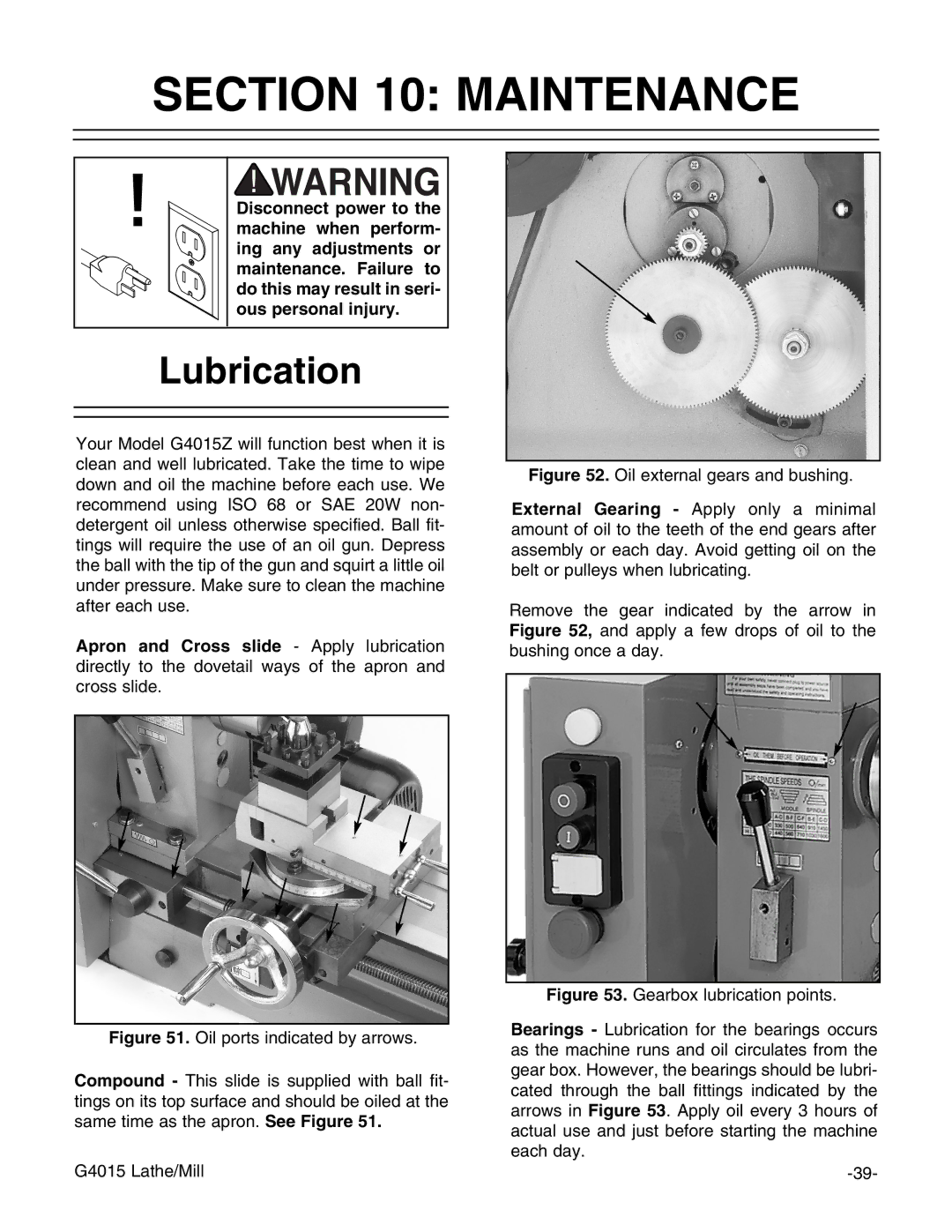

Apron and Cross slide - Apply lubrication directly to the dovetail ways of the apron and cross slide.