Inch Threading

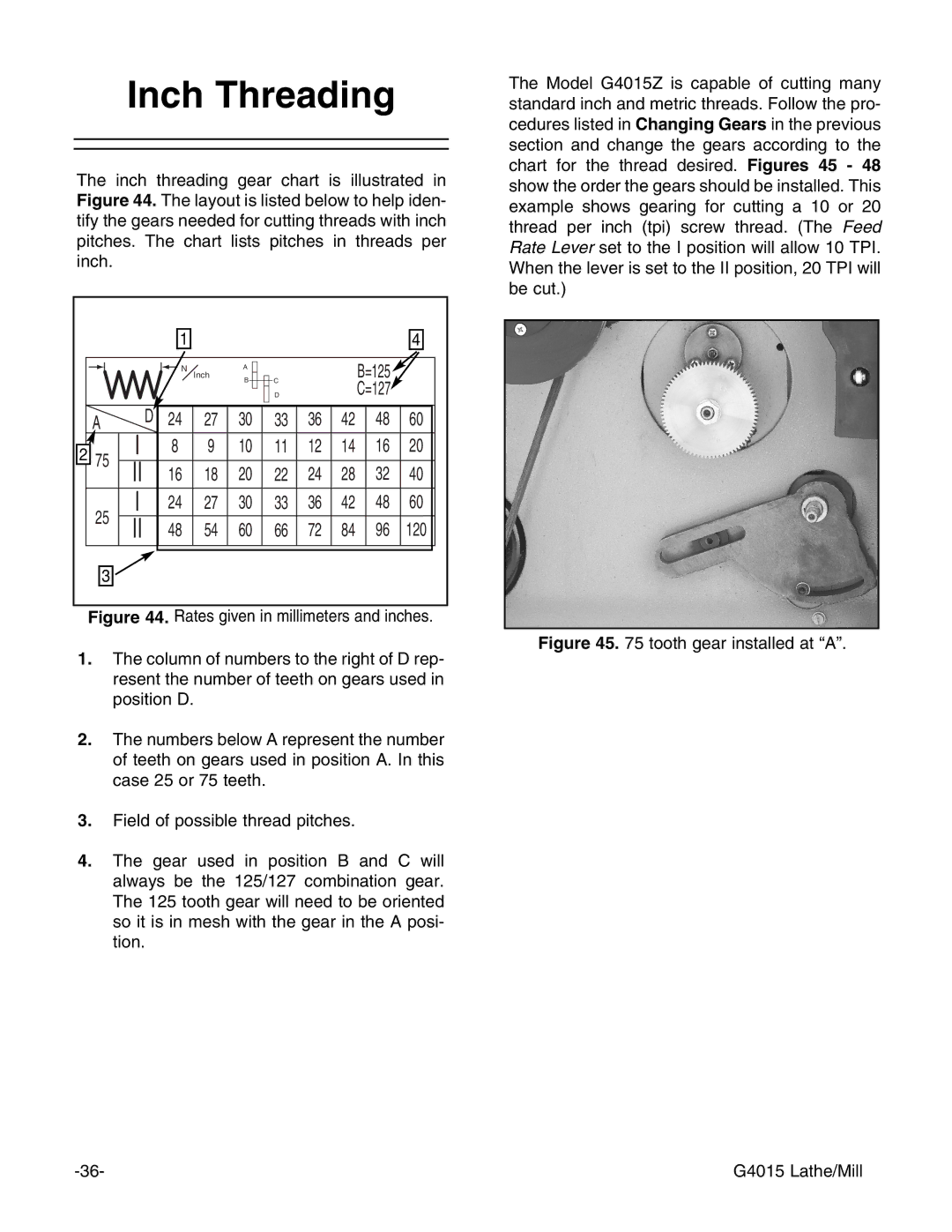

The inch threading gear chart is illustrated in Figure 44. The layout is listed below to help iden- tify the gears needed for cutting threads with inch pitches. The chart lists pitches in threads per inch.

|

| 1 |

|

|

|

|

|

| 4 |

|

| N | Inch | A |

|

|

| B=125 |

|

|

|

| B | C |

|

|

| ||

|

|

|

|

|

| C=127 |

| ||

|

|

|

|

| D |

|

|

| |

A | D | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 60 |

2 75 | I | 8 | 9 | 10 | 11 | 12 | 14 | 16 | 20 |

II | 16 | 18 | 20 | 22 | 24 | 28 | 32 | 40 | |

25 | I | 24 | 27 | 30 | 33 | 36 | 42 | 48 | 60 |

II | 48 | 54 | 60 | 66 | 72 | 84 | 96 | 120 | |

3 |

|

|

|

|

|

|

|

|

|

Figure 44. Rates given in millimeters and inches.

1.The column of numbers to the right of D rep- resent the number of teeth on gears used in position D.

2.The numbers below A represent the number of teeth on gears used in position A. In this case 25 or 75 teeth.

3.Field of possible thread pitches.

4.The gear used in position B and C will always be the 125/127 combination gear. The 125 tooth gear will need to be oriented so it is in mesh with the gear in the A posi- tion.

The Model G4015Z is capable of cutting many standard inch and metric threads. Follow the pro- cedures listed in Changing Gears in the previous section and change the gears according to the chart for the thread desired. Figures 45 - 48 show the order the gears should be installed. This example shows gearing for cutting a 10 or 20 thread per inch (tpi) screw thread. (The Feed Rate Lever set to the I position will allow 10 TPI. When the lever is set to the II position, 20 TPI will be cut.)

Figure 45. 75 tooth gear installed at “A”.

G4015 Lathe/Mill |