Motor - The bearings used in the motor are shielded and lubricated for life, therefore, no lubrication is necessary.

Lead Screw - Be sure to clean and lubricate the Lead Screw. There is also a bearing on the tail stock end that will require oil.

Headstock Gearbox - The oil in the headstock should be changed after the first 2 hours of use, then every 6 months, depending on usage. We recommend that a light weight, non detergent oil be used. Viscosity can range from 10W to 30W and may include

To remove the oil in the gear box, remove the change gear directly under the spindle, remove the cap screw indicated in Figure 55 and place a can under the drain hole to collect the waste oil.

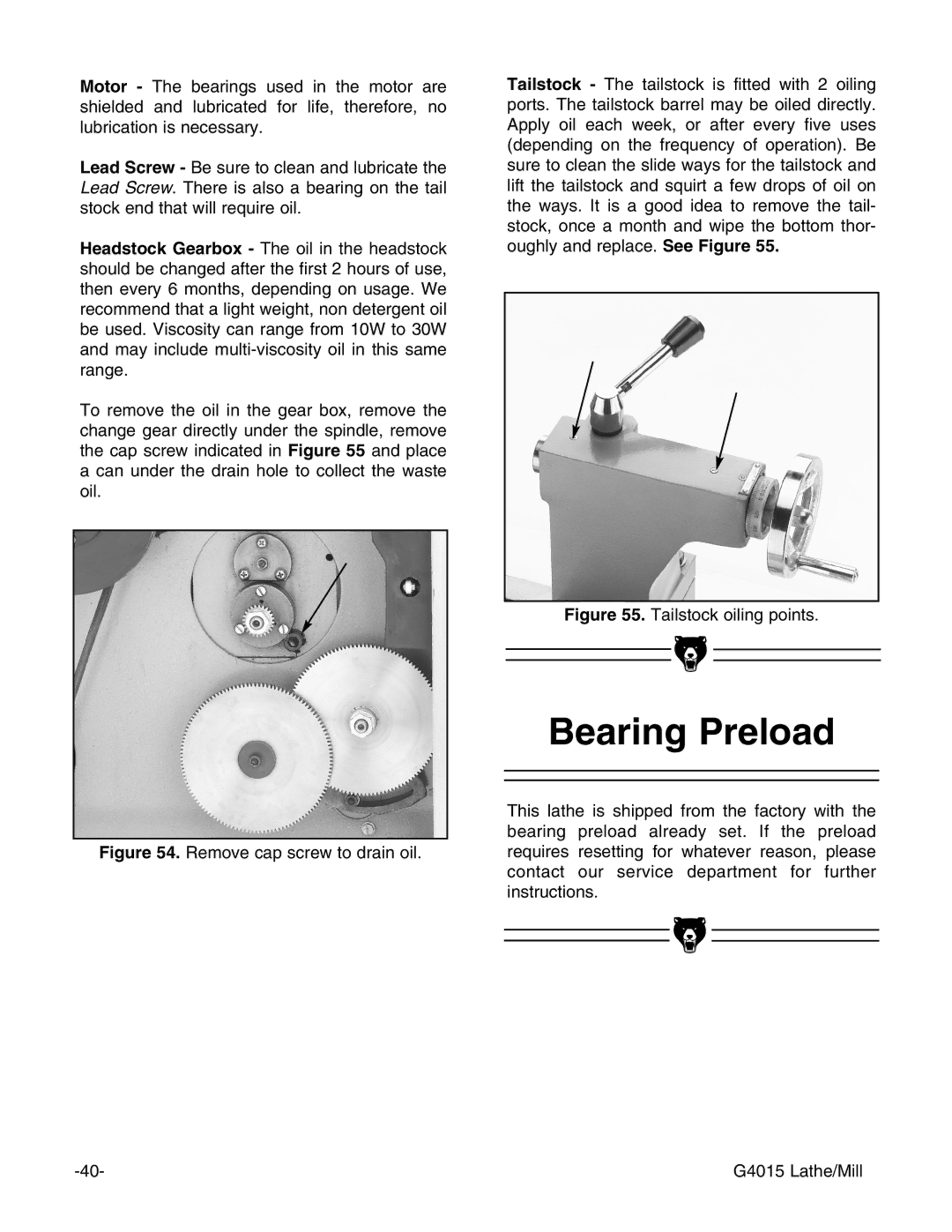

Tailstock - The tailstock is fitted with 2 oiling ports. The tailstock barrel may be oiled directly. Apply oil each week, or after every five uses (depending on the frequency of operation). Be sure to clean the slide ways for the tailstock and lift the tailstock and squirt a few drops of oil on the ways. It is a good idea to remove the tail- stock, once a month and wipe the bottom thor- oughly and replace. See Figure 55.

Figure 55. Tailstock oiling points.

Bearing Preload

Figure 54. Remove cap screw to drain oil.

This lathe is shipped from the factory with the bearing preload already set. If the preload requires resetting for whatever reason, please contact our service department for further instructions.

|

|

|

|

|

|

|

|

|

| G4015 Lathe/Mill | |

|

|