Fan And Heater | FAN SERVICE |

|

|

Motors used in GSI fan units are all standard NEMA frame motors and are specially designed for use in crop drying applications. Most of the replace- ment parts for these motors are handled by authorized service stations of the various motor manufacturers.

1.Always disconnect and lock out power before working on or around fan motor and electrical components.

2.Malfunctioning electrical components should be checked by a qualified electrician.

3.For extra motor life, any electric motor should be run for 30 minutes, once a month. This will help eliminate any damaging mois- ture

4.If excess vibration shows up at some point when the fan has been running smoothly, check the blade for these conditions:

a.Fans setting idle in the summer offer an excellent place for mud dobbers to build their nests. A mud dobber nest on the back of the fan blade will cause the fan to be out of balance and vibrate.

b. | Also, mice have been | known to |

nest in | the back | of a blade. |

When the fan is

started the centrifugal force kills the mice, but throws the blade out of balance.

|

|

|

|

| Lubrication |

|

| |

This is a ball bearing motor. |

|

|

|

|

|

| ||

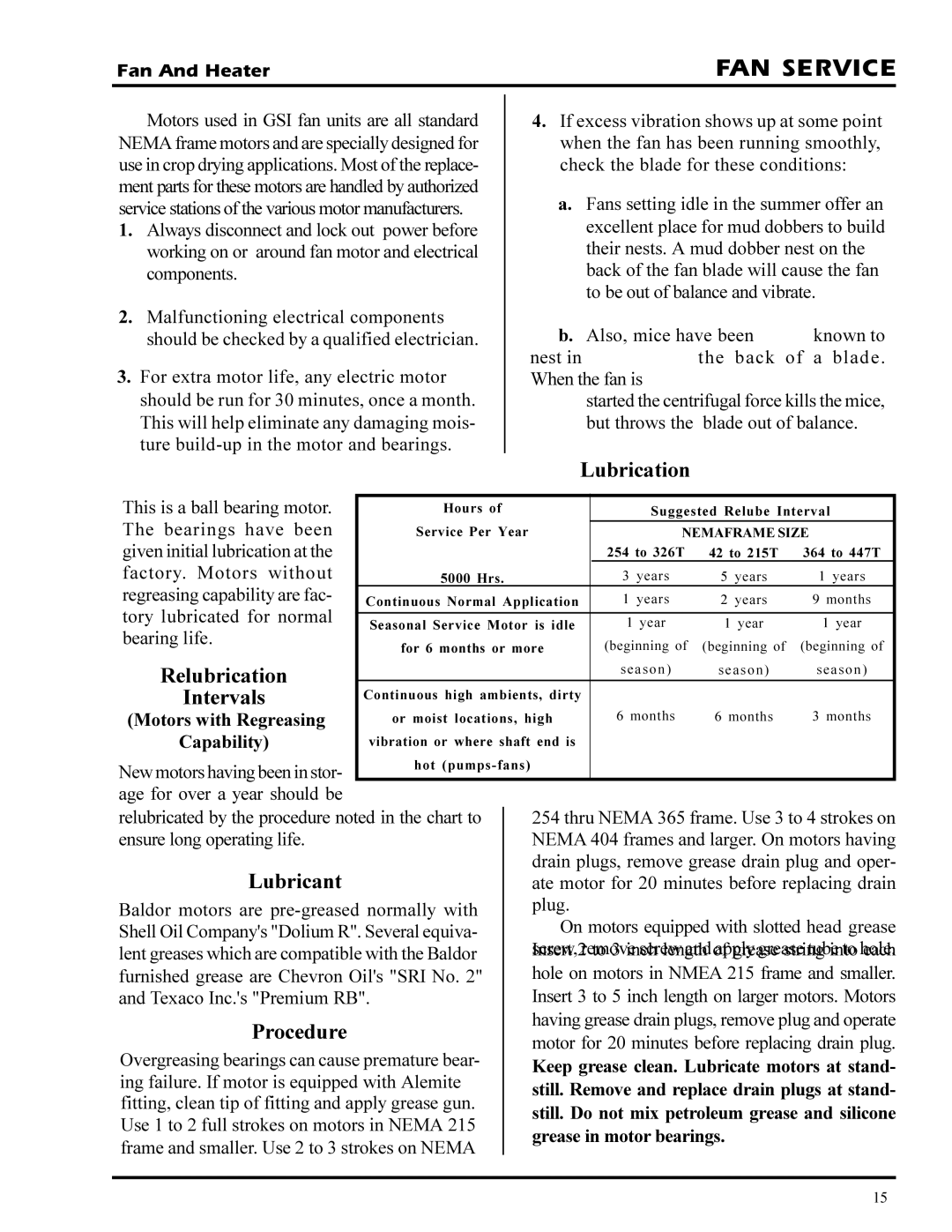

Hours of |

|

| Suggested Relube Interval | |||||

The bearings have been | Service Per Year |

|

|

| ||||

|

| NEMAFRAME SIZE | ||||||

given initial lubrication at the |

|

|

|

|

| 254 to 326T | 42 to 215T | 364 to 447T |

factory. Motors without | 5000 Hrs. |

|

| 3 years | 5 years | 1 years | ||

regreasing capability are fac- | Continuous Normal Application |

| 1 years | 2 years | 9 months | |||

tory lubricated for normal |

|

|

|

|

|

|

|

|

Seasonal Service Motor is idle |

| 1 year | 1 year | 1 year | ||||

bearing life. |

| |||||||

for 6 months or more |

| (beginning of | (beginning of | (beginning of | ||||

|

| |||||||

Relubrication |

|

|

|

|

| season) | season) | season) |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

Intervals | Continuous high ambients, dirty | 6 months | 6 months | 3 months | ||||

(Motors with Regreasing | or moist locations, high |

| ||||||

Capability) | vibration or where shaft end is |

|

|

|

| |||

New motors having been in stor- | hot |

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

age for over a year should be |

|

|

|

|

|

|

|

|

relubricated by the procedure noted in the chart to |

|

| 254 thru NEMA 365 frame. Use 3 to 4 strokes on | |||||

| ||||||||

ensure long operating life. |

|

|

| NEMA 404 frames and larger. On motors having | ||||

Lubricant |

|

|

| drain plugs, remove grease drain plug and oper- | ||||

|

|

| ate motor for 20 minutes before replacing drain | |||||

Baldor motors are |

|

| plug. |

|

|

|

| |

Shell Oil Company's "Dolium R". Several equiva- |

|

| On motors equipped with slotted head grease | |||||

lent greases which are compatible with the Baldor |

|

| Insscrew,rt 2removeto 3 inchscrewlengthandofapplygreasegreasestringtubeinto holeeach. | |||||

furnished grease are Chevron Oil's "SRI No. 2" |

|

| hole on motors in NMEA 215 frame and smaller. | |||||

and Texaco Inc.'s "Premium RB". |

|

| Insert 3 to 5 inch length on larger motors. Motors | |||||

Procedure |

|

|

| having grease drain plugs, remove plug and operate | ||||

|

|

| motor for 20 minutes before replacing drain plug. | |||||

Overgreasing bearings can cause premature bear- |

|

| ||||||

|

| Keep grease clean. Lubricate motors at stand- | ||||||

ing failure. If motor is equipped with Alemite |

|

| ||||||

|

| still. Remove and replace drain plugs at stand- | ||||||

fitting, clean tip of fitting and apply grease gun. |

|

| ||||||

|

| still. Do not mix petroleum grease and silicone | ||||||

Use 1 to 2 full strokes on motors in NEMA 215 |

|

| ||||||

|

| grease in motor bearings. |

| |||||

frame and smaller. Use 2 to 3 strokes on NEMA |

|

|

| |||||

|

|

|

|

|

|

| ||

15