Fan and Heater

FENWAL-SERIES 05-14

Operation continued

This manual reset button can be located on the ignitor board or remotely on a control panel. (Consult factory for remove mounting agency approvals). Should the flame not be established during the trial for ignition period, the system will

Flame Sensing

The Series

Electrode Application

(Burner Manufacturer only)

1.Manually ignite burner flame to observe flame characteristics.

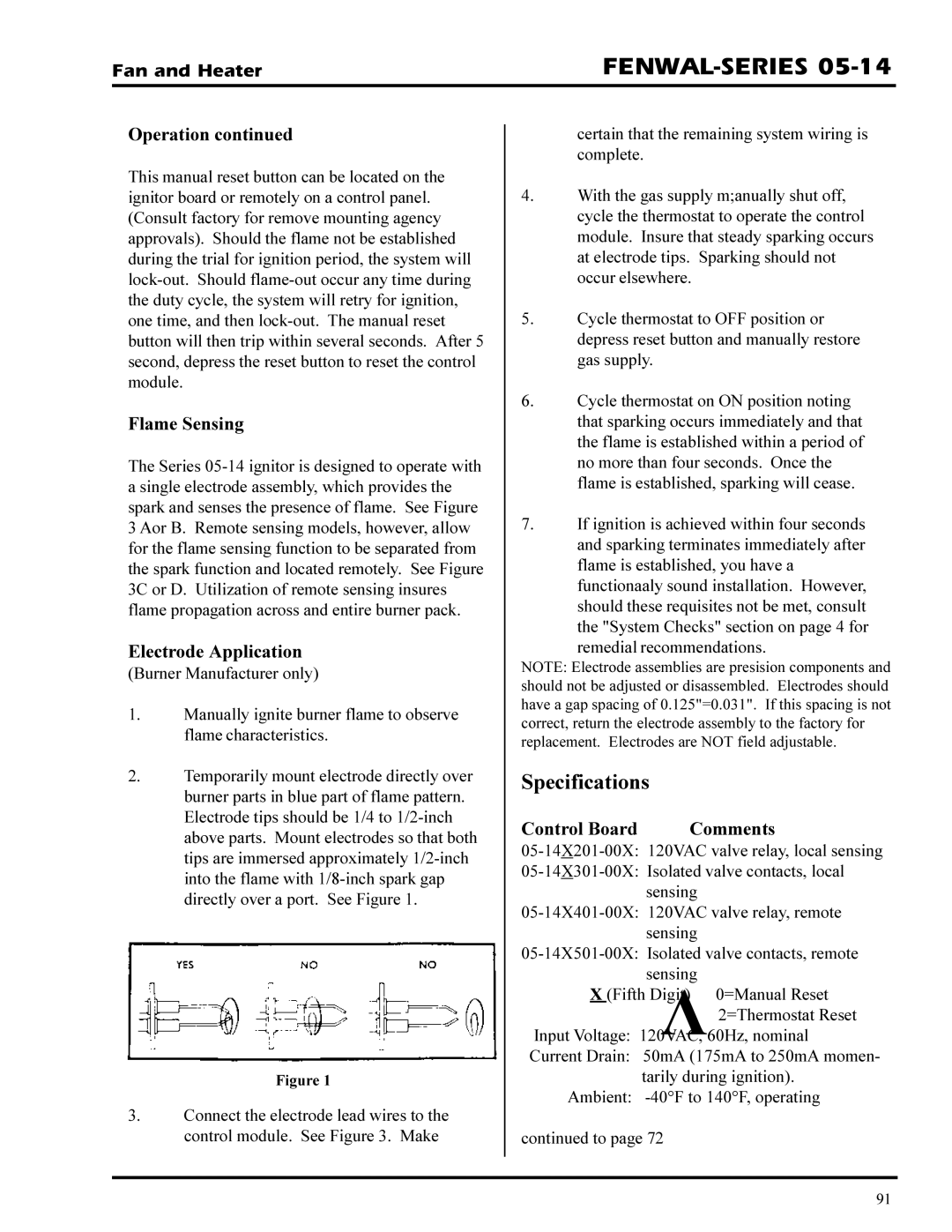

2.Temporarily mount electrode directly over burner parts in blue part of flame pattern. Electrode tips should be 1/4 to

Figure 1

3.Connect the electrode lead wires to the control module. See Figure 3. Make

certain that the remaining system wiring is complete.

4.With the gas supply m;anually shut off, cycle the thermostat to operate the control module. Insure that steady sparking occurs at electrode tips. Sparking should not occur elsewhere.

5.Cycle thermostat to OFF position or depress reset button and manually restore gas supply.

6.Cycle thermostat on ON position noting that sparking occurs immediately and that the flame is established within a period of no more than four seconds. Once the flame is established, sparking will cease.

7.If ignition is achieved within four seconds and sparking terminates immediately after flame is established, you have a functionaaly sound installation. However, should these requisites not be met, consult the "System Checks" section on page 4 for

remedial recommendations.

NOTE: Electrode assemblies are presision components and should not be adjusted or disassembled. Electrodes should have a gap spacing of 0.125"=0.031". If this spacing is not correct, return the electrode assembly to the factory for replacement. Electrodes are NOT field adjustable.

Specifications

Control Board Comments

X (Fifth Digit) 0=Manual Reset | |

V | 2=Thermostat Reset |

| |

Input Voltage: 120 AC, 60Hz, nominal

Current Drain: 50mA (175mA to 250mA momen- tarily during ignition).

Ambient:

91