GTO PRO SL-1000 SERIES TECHNICAL SPECIFICATIONS

DRIVE

•Powered by a 12 V motor with integral case hardened steel gear reduction to 90 rpm. Generates 155 in. lb. of torque at 12 V. Motor temperature range

•Gate velocity: 1 ft/s.

POWER

•The PRO

•Battery charge for PRO

NOTE: The transformer should not be connected directly to any battery. Transformer must be connected with a

minimum of 16 gauge,

•Battery charge maintained by GTO Solar Panel Charger: float voltage 14.5 Vdc output from a

193/8” x 151/4” silicon alloy panel. Generates minimum of 10 W at 600 mA. Gated diode on the control board prevents battery discharge.

CONTROL

•GTO microprocessor controlled board with temperature compensated circuits.

•GTO

•Limit controls are mechanical. Normally open contact.

•Adjustable

•Power terminal block accommodates a transformer and solar panels.

•Operator terminal blocks accommodate safety edges and photoelectric sensors for opening and closing modes.

•Fully compatible accessory terminal block provides connections for safety loops, wands, intercoms, card readers, phone systems, etc.

•DIP switches simplify setup of gate operator.

•audio entrapment alarm sounds if unit obstructs twice while opening or closing.

OPERATIONAL CAPACITY

•The GTO/PRO

•The GTO/PRO

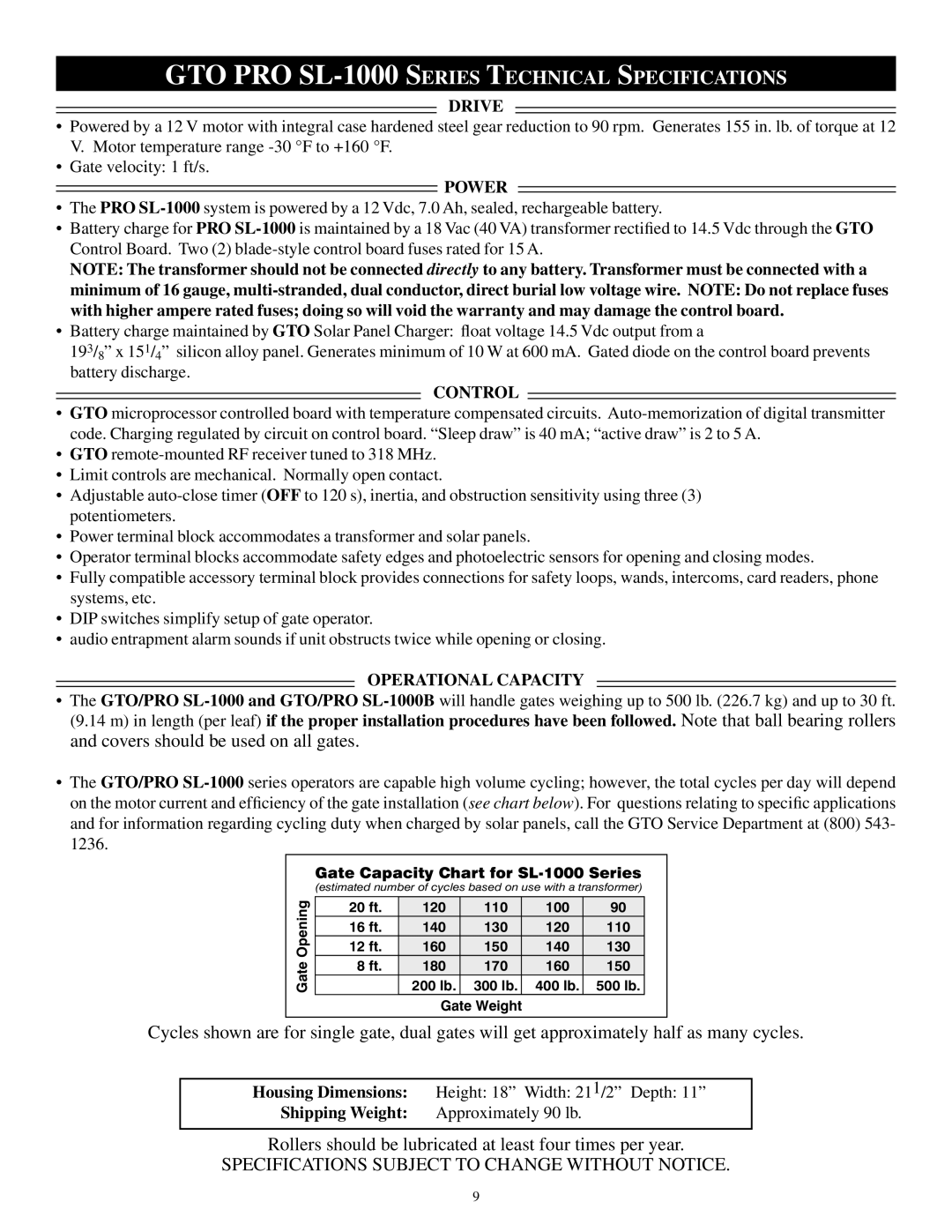

Gate Capacity Chart for SL-1000 Series

(estimated number of cycles based on use with a transformer)

Gate Opening

20 ft. | 120 | 110 | 100 | 90 |

16 ft. | 140 | 130 | 120 | 110 |

12 ft. | 160 | 150 | 140 | 130 |

8 ft. | 180 | 170 | 160 | 150 |

200 lb. 300 lb. 400 lb. 500 lb.

Gate Weight

Cycles shown are for single gate, dual gates will get approximately half as many cycles.

Housing Dimensions: | Height: 18” Width: 211/2” Depth: 11” |

Shipping Weight: | Approximately 90 lb. |

|

|

Rollers should be lubricated at least four times per year.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

9