|

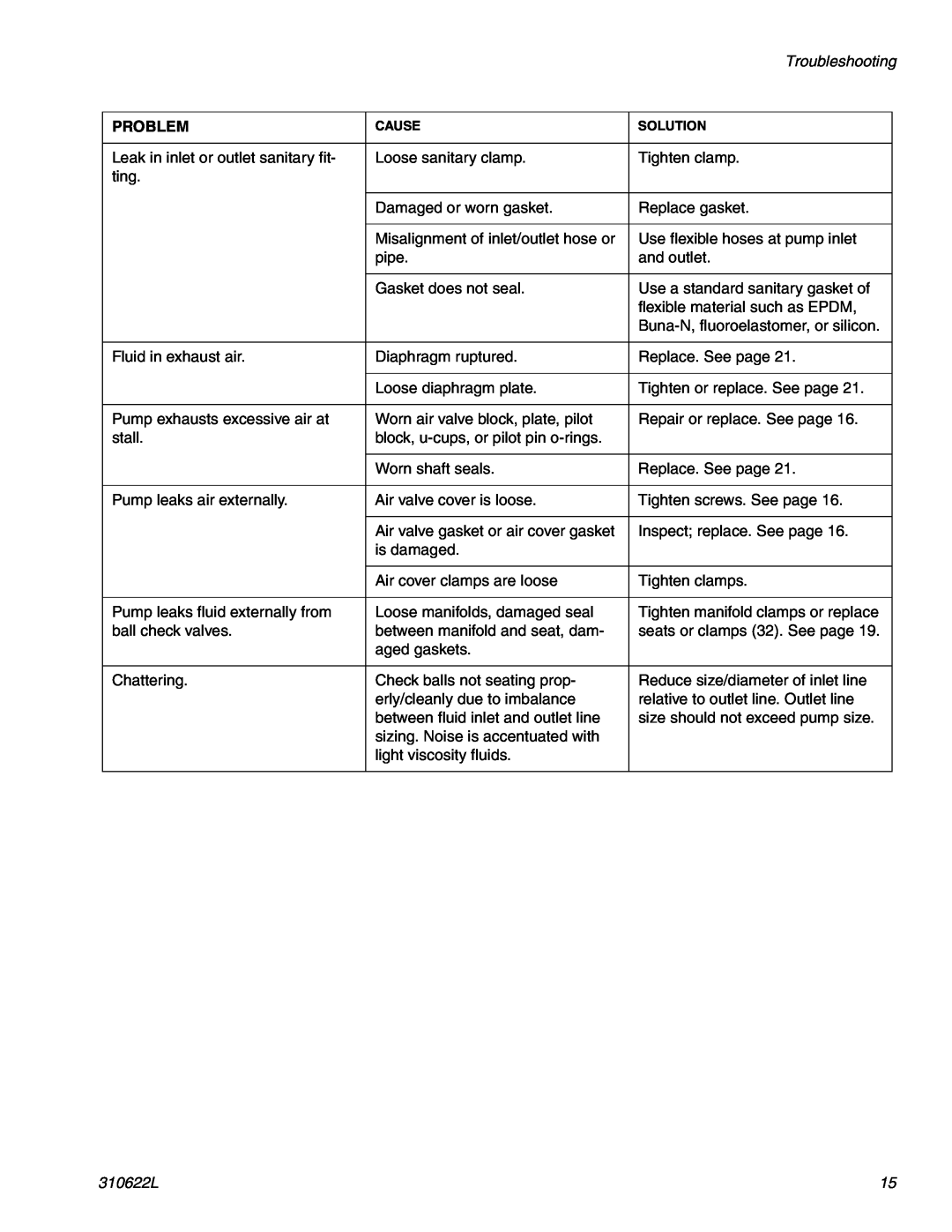

| Troubleshooting | |

|

|

|

|

PROBLEM | CAUSE | SOLUTION |

|

|

|

|

|

Leak in inlet or outlet sanitary fit- | Loose sanitary clamp. | Tighten clamp. |

|

ting. |

|

|

|

|

|

|

|

| Damaged or worn gasket. | Replace gasket. |

|

|

|

|

|

| Misalignment of inlet/outlet hose or | Use flexible hoses at pump inlet |

|

| pipe. | and outlet. |

|

|

|

|

|

| Gasket does not seal. | Use a standard sanitary gasket of |

|

|

| flexible material such as EPDM, |

|

|

|

|

|

|

|

|

|

Fluid in exhaust air. | Diaphragm ruptured. | Replace. See page 21. |

|

|

|

|

|

| Loose diaphragm plate. | Tighten or replace. See page 21. |

|

|

|

|

|

Pump exhausts excessive air at | Worn air valve block, plate, pilot | Repair or replace. See page 16. |

|

stall. | block, |

|

|

|

|

|

|

| Worn shaft seals. | Replace. See page 21. |

|

|

|

|

|

Pump leaks air externally. | Air valve cover is loose. | Tighten screws. See page 16. |

|

|

|

|

|

| Air valve gasket or air cover gasket | Inspect; replace. See page 16. |

|

| is damaged. |

|

|

|

|

|

|

| Air cover clamps are loose | Tighten clamps. |

|

|

|

|

|

Pump leaks fluid externally from | Loose manifolds, damaged seal | Tighten manifold clamps or replace |

|

ball check valves. | between manifold and seat, dam- | seats or clamps (32). See page 19. |

|

| aged gaskets. |

|

|

|

|

|

|

Chattering. | Check balls not seating prop- | Reduce size/diameter of inlet line |

|

| erly/cleanly due to imbalance | relative to outlet line. Outlet line |

|

| between fluid inlet and outlet line | size should not exceed pump size. |

|

| sizing. Noise is accentuated with |

|

|

| light viscosity fluids. |

|

|

|

|

|

|

310622L | 15 |