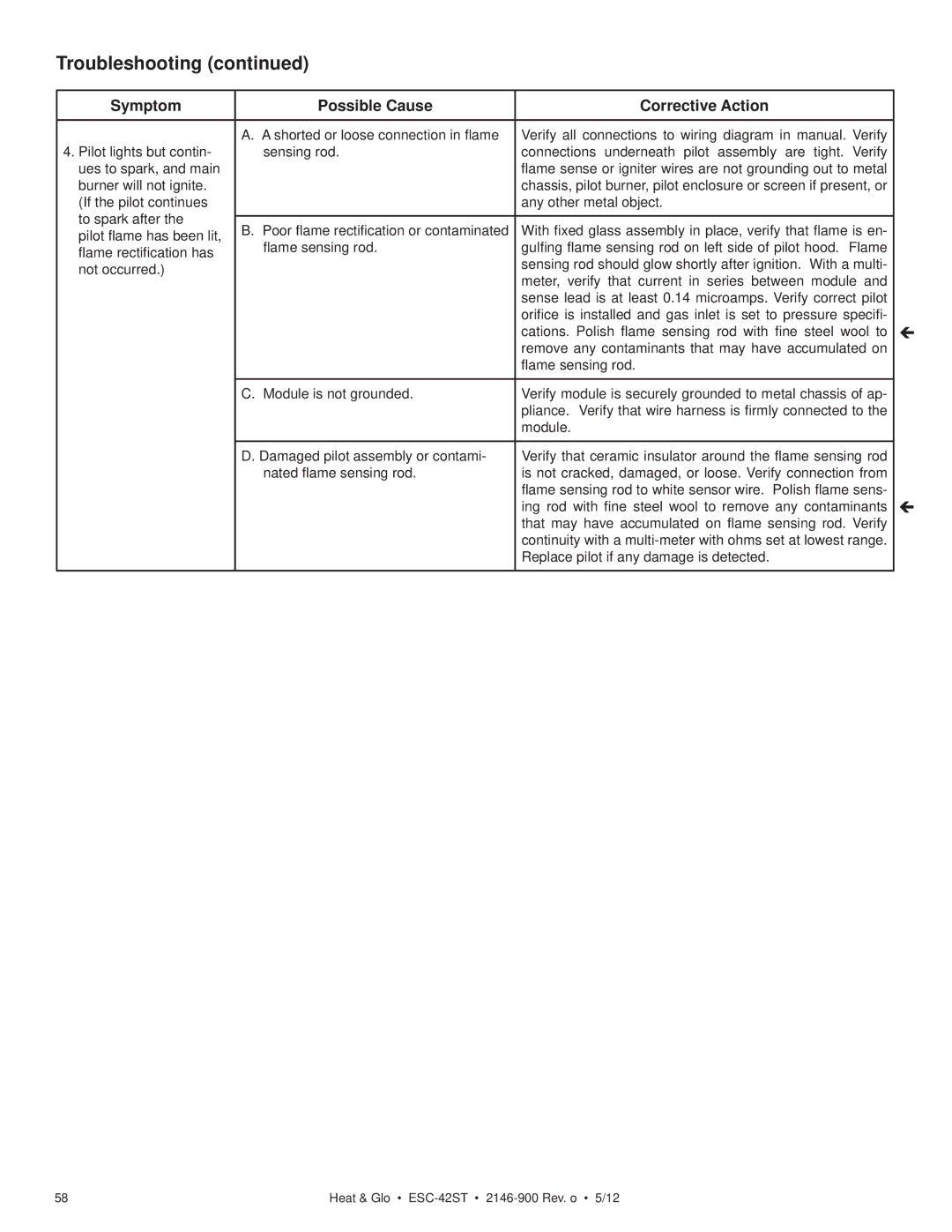

Troubleshooting (continued)

Symptom | Possible Cause | Corrective Action |

|

|

|

|

|

| A. A shorted or loose connection in flame | Verify all connections to wiring diagram in manual. Verify |

|

4. Pilot lights but contin- | sensing rod. | connections underneath pilot assembly are tight. Verify |

|

ues to spark, and main |

| flame sense or igniter wires are not grounding out to metal |

|

burner will not ignite. |

| chassis, pilot burner, pilot enclosure or screen if present, or |

|

(If the pilot continues |

| any other metal object. |

|

to spark after the |

|

|

|

B. Poor flame rectification or contaminated | With fixed glass assembly in place, verify that flame is en- |

| |

pilot flame has been lit, |

| ||

flame sensing rod. | gulfing flame sensing rod on left side of pilot hood. Flame |

| |

flame rectification has |

| ||

| sensing rod should glow shortly after ignition. With a multi- |

| |

not occurred.) |

|

| |

| meter, verify that current in series between module and |

| |

|

|

| |

|

| sense lead is at least 0.14 microamps. Verify correct pilot |

|

|

| orifice is installed and gas inlet is set to pressure specifi- | |

|

| cations. Polish flame sensing rod with fine steel wool to | |

|

| remove any contaminants that may have accumulated on |

|

|

| flame sensing rod. |

|

|

|

|

|

| C. Module is not grounded. | Verify module is securely grounded to metal chassis of ap- |

|

|

| pliance. Verify that wire harness is firmly connected to the |

|

|

| module. |

|

|

|

|

|

| D. Damaged pilot assembly or contami- | Verify that ceramic insulator around the flame sensing rod |

|

| nated flame sensing rod. | is not cracked, damaged, or loose. Verify connection from |

|

|

| flame sensing rod to white sensor wire. Polish flame sens- | |

|

| ing rod with fine steel wool to remove any contaminants | |

|

| that may have accumulated on flame sensing rod. Verify |

|

|

| continuity with a |

|

|

| Replace pilot if any damage is detected. |

|

|

|

|

|

58 | Heat & Glo • |