H-IM-79E specifications

Heatcraft Refrigeration Products has long been a leader in eco-friendly and efficient cooling solutions, and the H-IM-79E is a prime example of their commitment to innovation and sustainability. Designed for commercial use, the H-IM-79E is a high-performance refrigeration unit ideal for supermarkets, convenience stores, and restaurants, where reliable temperature control is essential.One of the standout features of the H-IM-79E is its energy efficiency. This unit employs advanced compressor technology that optimizes power consumption without sacrificing cooling performance. In addition, it is designed to minimize operational costs, making it an attractive option for businesses looking to reduce their energy bills while maintaining high standards of refrigeration.

The H-IM-79E integrates a robust refrigerant management system that uses environmentally friendly refrigerants, aligning with Heatcraft's commitment to reducing the carbon footprint of their products. This not only helps businesses comply with environmental regulations but also promotes a healthier planet for future generations.

Another key characteristic of the H-IM-79E is its superior temperature stability. The unit is equipped with precision temperature control technology that ensures consistent cooling performance, preventing temperature fluctuations that can compromise food quality and safety. This reliability is crucial in commercial settings where maintaining optimal storage conditions is essential.

The design of the H-IM-79E is also noteworthy. It features a compact footprint, allowing it to fit seamlessly into various commercial environments without taking up valuable floor space. Additionally, the unit is built with durable materials, ensuring longevity and minimizing maintenance needs.

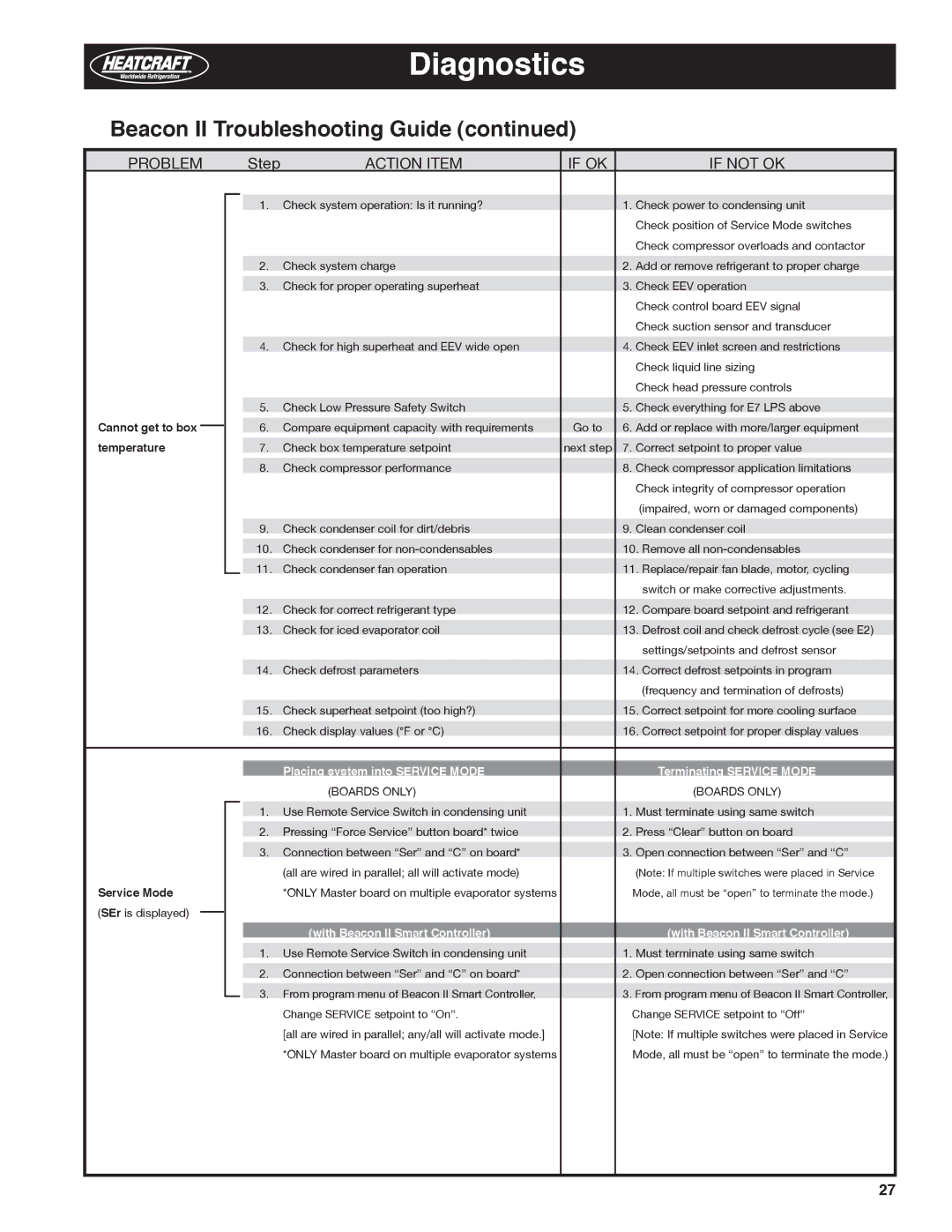

User-friendly interfaces make the H-IM-79E easy to operate. It includes advanced monitoring and diagnostics capabilities, allowing business owners to track performance in real-time and address potential issues before they escalate. The incorporation of smart technologies means that operators can remotely monitor and control the system, providing flexibility and peace of mind.

In summary, the Heatcraft Refrigeration Products H-IM-79E stands out for its energy efficiency, eco-friendly refrigerant use, reliable temperature control, compact design, and user-friendly features. This combination of attributes makes it an ideal choice for businesses that prioritize both sustainability and performance in their refrigeration needs.