5)Disconnect the gauge manifold hose from the vacuum pump and attach it to a refrigerant service cylinder. Remember to loosen the connection and purge the air from the hose. See the nameplate inside the appliance for the required refrigerant charge. Hoshizaki recommends only virgin refrigerant or reclaimed refrigerant which meets ARI Standard 700 (latest edition) be used.

6)A liquid charge is required for charging an

7)Allow the system to charge with liquid until the proper charge weight is met.

8)If necessary, add any remaining charge to the system through the

NOTICE! To prevent compressor damage, use a throttling valve or liquid dispensing device to add the remaining liquid charge through the

9)Close the high and

10)Cap the access valves to prevent a possible leak.

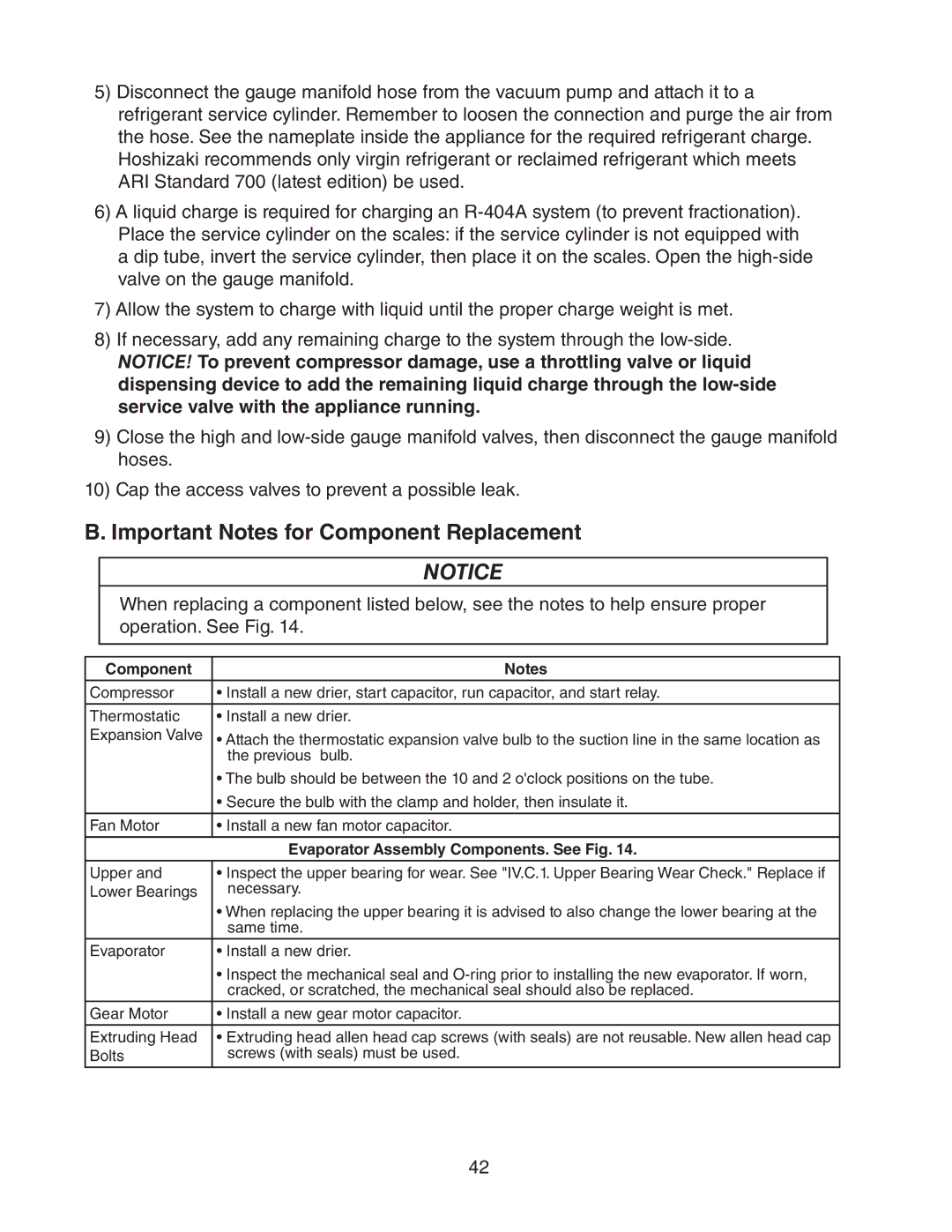

B.Important Notes for Component Replacement

NOTICE

When replacing a component listed below, see the notes to help ensure proper operation. See Fig. 14.

Component | Notes |

|

|

Compressor | • Install a new drier, start capacitor, run capacitor, and start relay. |

|

|

Thermostatic | • Install a new drier. |

Expansion Valve | • Attach the thermostatic expansion valve bulb to the suction line in the same location as |

| the previous bulb. |

| • The bulb should be between the 10 and 2 o'clock positions on the tube. |

| • Secure the bulb with the clamp and holder, then insulate it. |

|

|

Fan Motor | • Install a new fan motor capacitor. |

|

|

| Evaporator Assembly Components. See Fig. 14. |

|

|

Upper and | • Inspect the upper bearing for wear. See "IV.C.1. Upper Bearing Wear Check." Replace if |

Lower Bearings | necessary. |

| • When replacing the upper bearing it is advised to also change the lower bearing at the |

| same time. |

Evaporator | • Install a new drier. |

| • Inspect the mechanical seal and |

| cracked, or scratched, the mechanical seal should also be replaced. |

Gear Motor | • Install a new gear motor capacitor. |

|

|

Extruding Head | • Extruding head allen head cap screws (with seals) are not reusable. New allen head cap |

Bolts | screws (with seals) must be used. |

|

|

42