INPUT STOP/START

10A FUSE

00 0 0 0 1/10

TOTAL HOURS

BATT.

CHRG.

11

1

2

10

3

4

5

6

NOTE

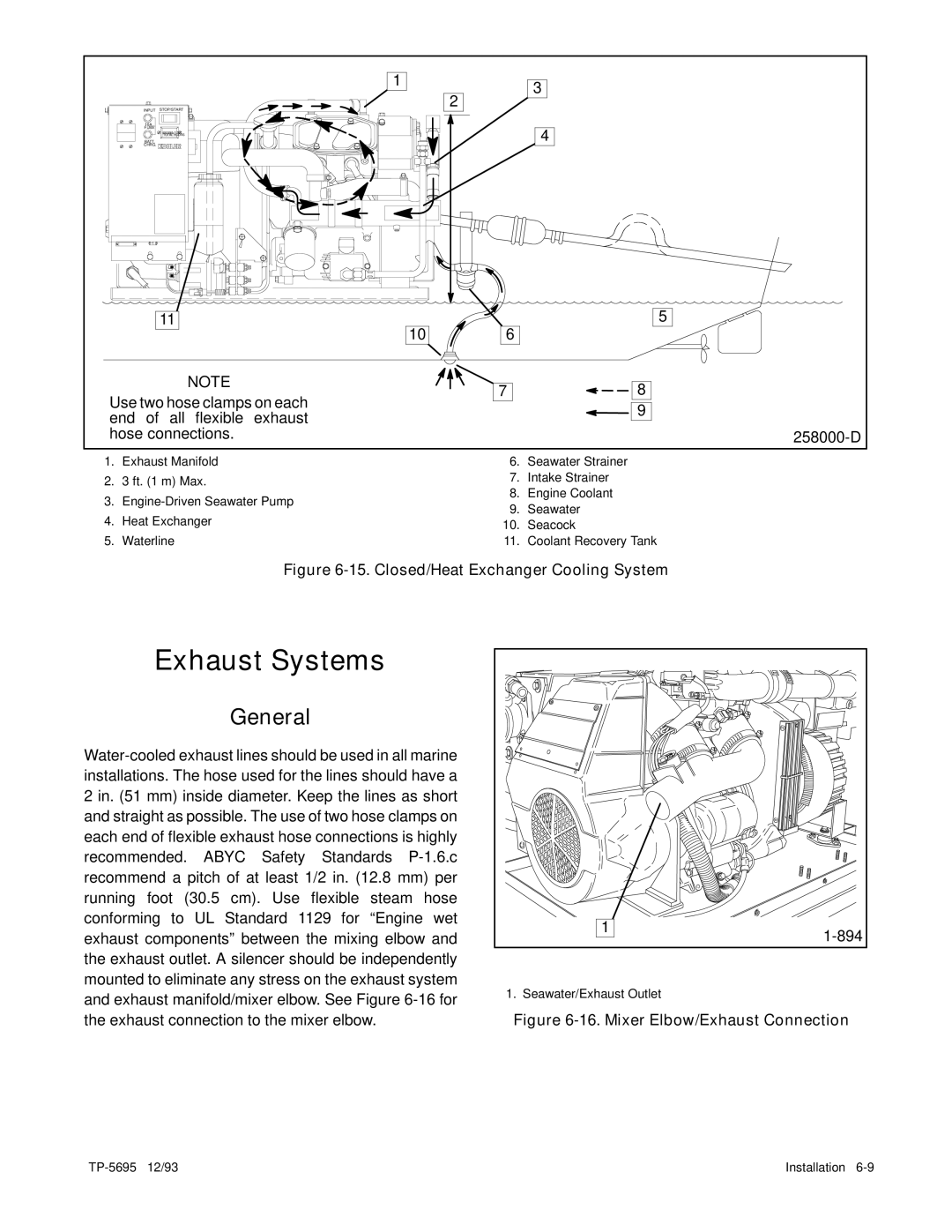

Use two hose clamps on each end of all flexible exhaust hose connections.

7

![]()

![]()

![]()

![]() 8

8

![]()

![]() 9

9

1. | Exhaust Manifold | 6. | Seawater Strainer | |

2. | 3 ft. (1 m) Max. | 7. | Intake Strainer | |

3. | 8. | Engine Coolant | ||

9. | Seawater | |||

4. | Heat Exchanger | |||

10. | Seacock | |||

5. | Waterline | 11. | Coolant Recovery Tank |

Figure 6-15. Closed/Heat Exchanger Cooling System

Exhaust Systems

General

1 | |

| |

1. Seawater/Exhaust Outlet |

|

Figure 6-16. Mixer Elbow/Exhaust Connection

Installation |